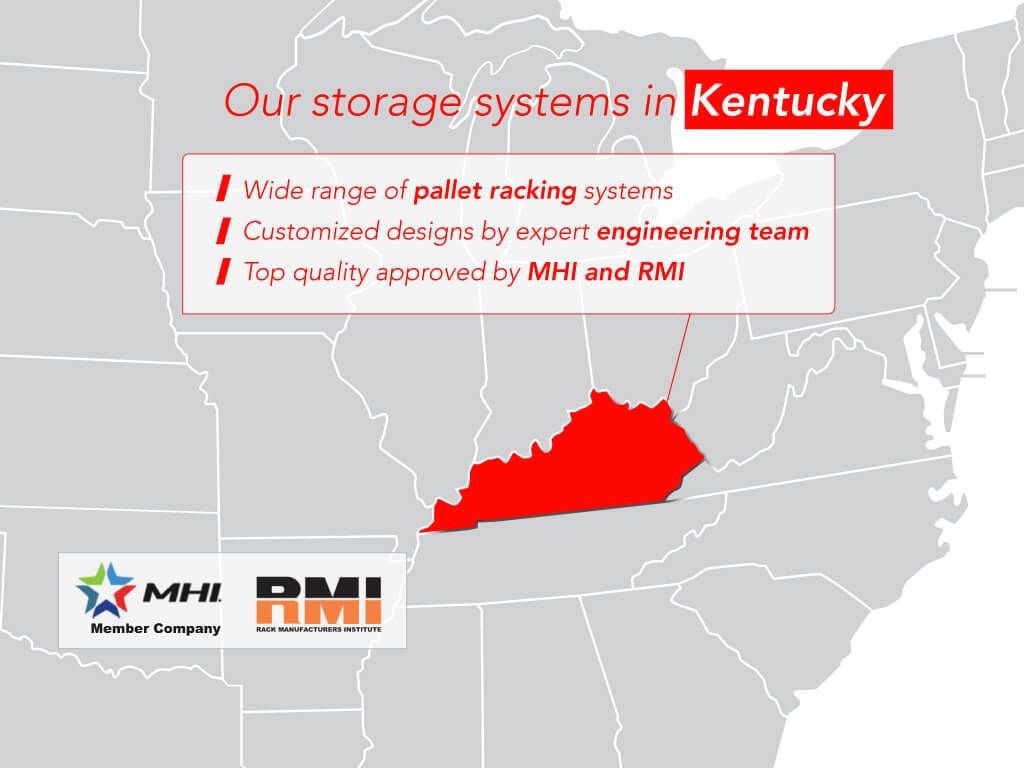

Pallet Racking systems in Kentucky

We create and produce pallet racking solutions for warehouses and distribution centers in Kentucky. Check out our high-quality racks that meet MHI and RMI standards.

Our Racking Systems for Warehouses

AR Racking, operating from its office in Charlotte, North Carolina, extends its comprehensive solutions to meet storage needs across Kentucky..

Catering to a spectrum of industries including food and chemicals, cold storage, retail, construction, and more, we offer tailored solutions for businesses of all sizes.

Our team of experts will advise you to choose the most suitable storage system for your warehouse.

Choosing the right pallet racking system depends on your available space, product type, and stock management needs

We offer all types of industrial storage systems:

|

|

Why choose AR Racking solutions?

AR Racking's warehouse racking is the preferred choice for businesses in Kentucky aiming to maximize storage capacity and enhance operational efficiency. With its versatility and dependability, AR Racking provides unparalleled solutions customized to address the distinct requirements of businesses across diverse industries.

Racking Solutions for all businesses

From heavy-duty to light-duty loads, we offer racks tailored to fit the diverse needs of every company.

Engineering Excellence and Innovation

At our core, we boast a full team of engineers dedicated to enhancing rack systems for peak efficiency and innovation.

Guaranteed On-Time Delivery

We take immense pride in our unwavering commitment to meeting delivery deadlines and providing exceptional service.

Durable Galvanized Racks

Built from galvanized steel, our racks deliver unmatched durability and corrosion resistance, ensuring long-lasting performance for your system.

Benchmark in the US market

AR Racking is a full member and collaborates with the following US associations:

Our Pallet Racks throughout Kentucky

AR Racking offers extensive solutions to fulfill storage demands throughout all cities in Kentucky.

Our team is dedicated to providing rapid, technical, and expert service, guaranteeing that your storage needs are fulfilled with utmost proficiency and effectiveness.

|

|

Wide range of Pallet Racking Systems

AR Racking offers a comprehensive range of pallet racking systems tailored to diverse industrial storage demands.

Selective Pallet Racking

The Selective Pallet Racking system is designed for efficient and functional storage of pallets using forklifts. In this system, forklifts access the goods through aisles that run parallel to the racks

VNA Racking

Very Narrow Aisle Pallet Racking (VNA) is a compact version of standard adjustable pallet racking systems. It creates a high-density storage system, increasing warehouse capacity without needing more space.

Drive in Racking

The Drive in and Drive Through Racking System is a high-density storage solution that maximizes available space and height in the warehouse by reducing the forklift operating aisles.

Mobile Pallet Racking

Mobile Pallet Racking (AR Mobile) is a system where the pallet racks are placed on chassis or mobile bases guided through fixed tracks on the floor.

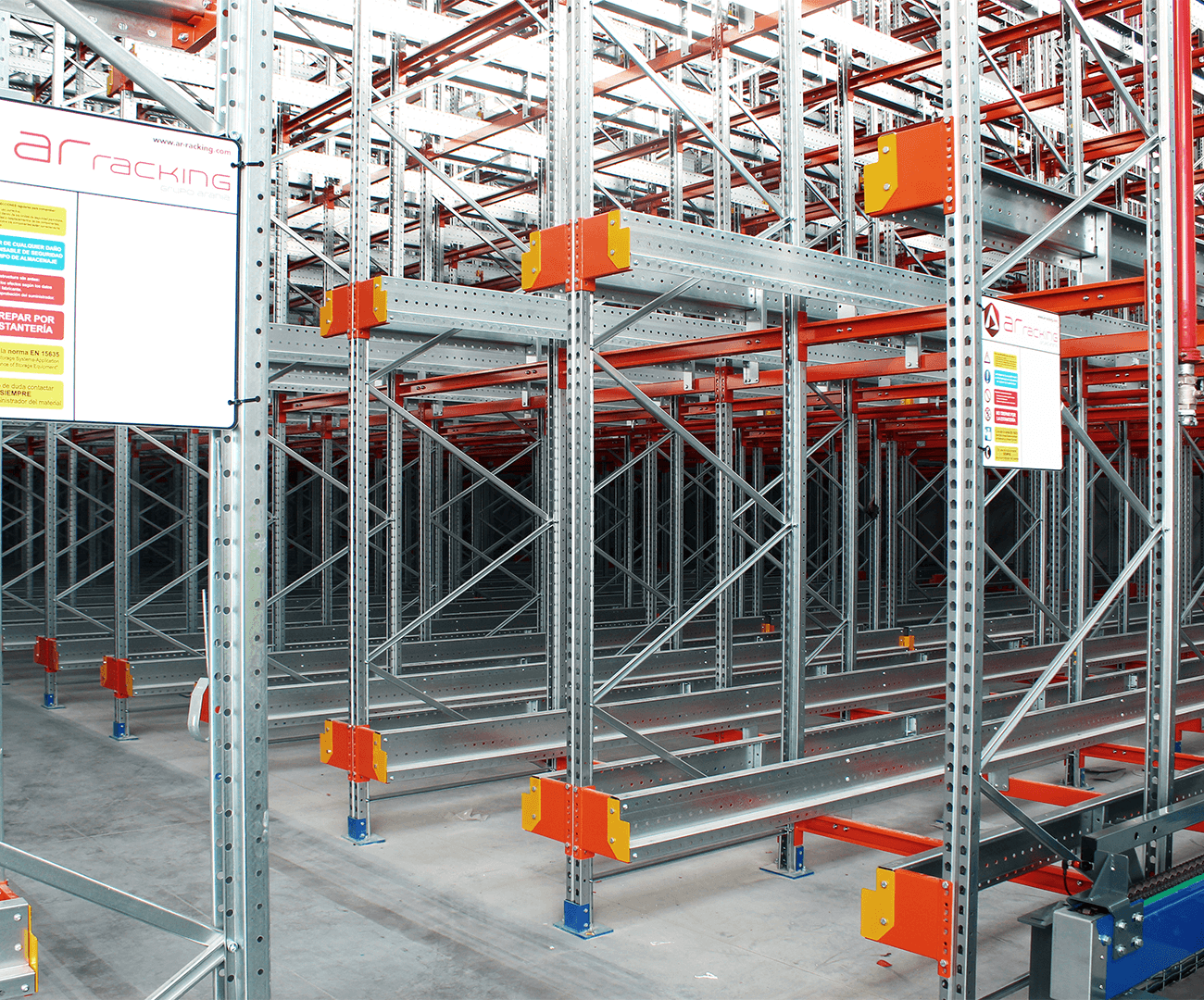

AR Pallet Shuttle

The Pallet Shuttle (AR Shuttle) is a high-density compact storage solution that uses powered shuttles to automatically carry loads into the rack. Hence, there is an optimum use of storage space and workplace accident rates are also reduced.

Pallet Flow Racking (FIFO)

Push Back Racking (LIFO)

Push-back Pallet Racking features a single loading and unloading area at the front. Pallets are stored by pushing each new load toward the back of the rack.

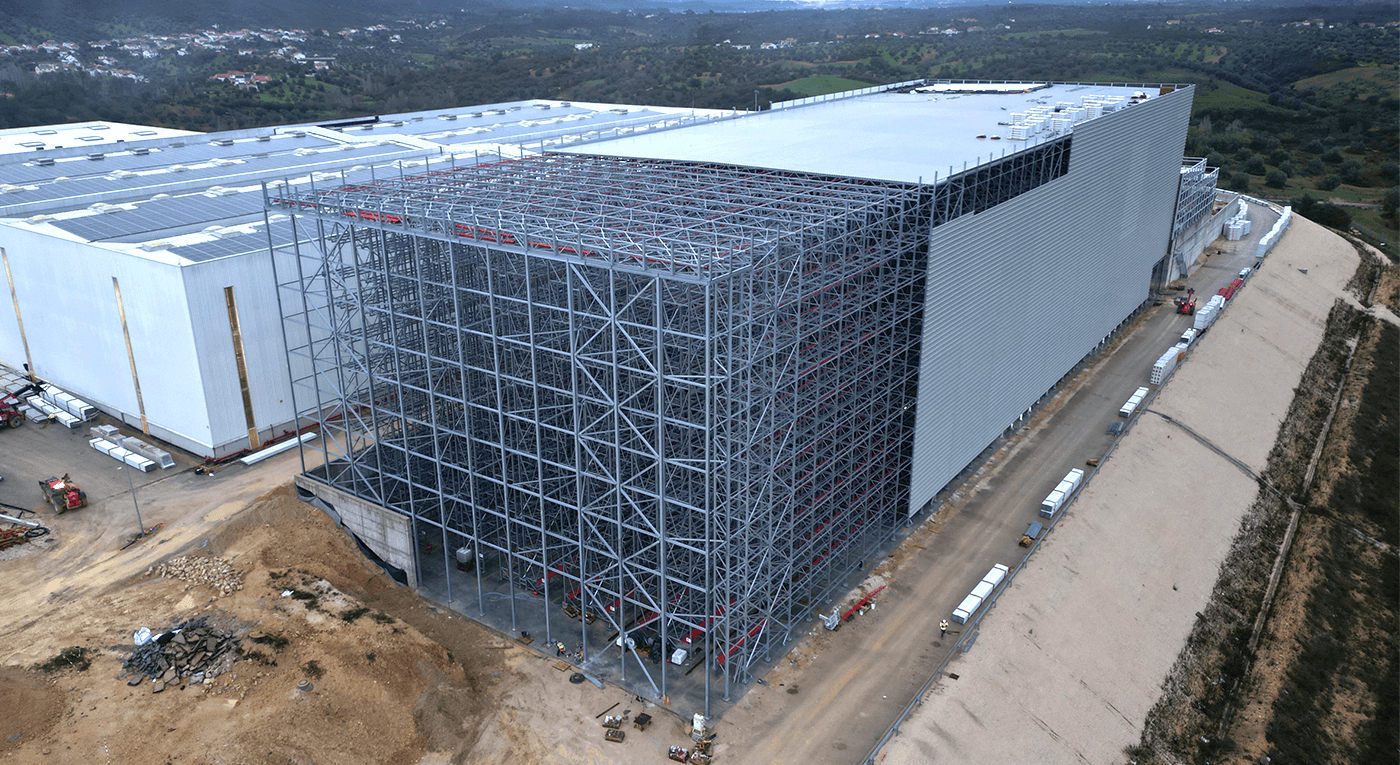

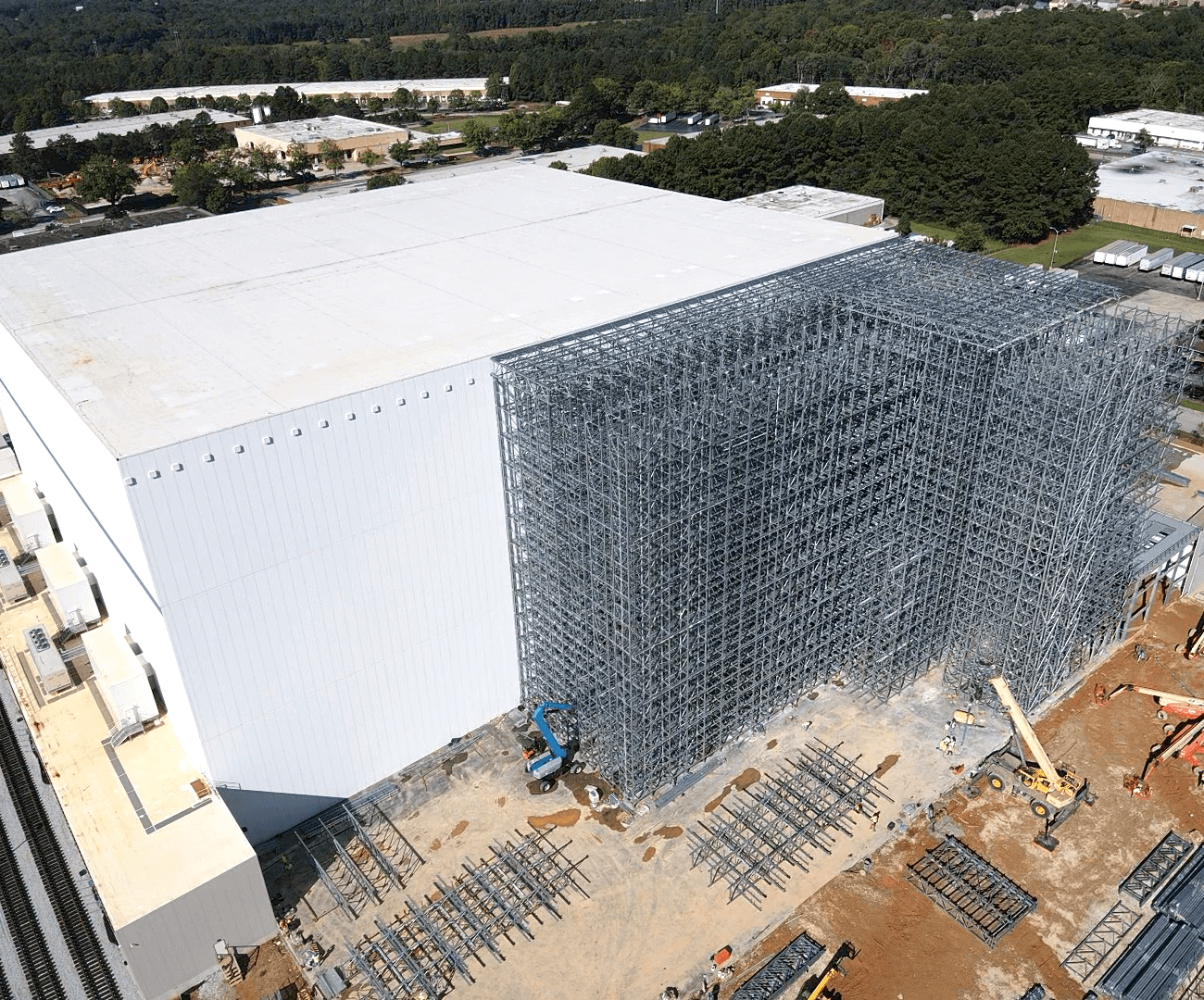

Rack Supported Building

Rack Supported Buildings integrate automated storage systems into the building’s structure, optimizing vertical space. They are versatile and can be tailored to meet specific needs.

Excellent service and on-time delivery

Engineering and efficiency in our racks

AR Racking offers a complete customized consultancy service for storage projects, ensuring that clients find the optimal storage solution to meet their specific requirements.

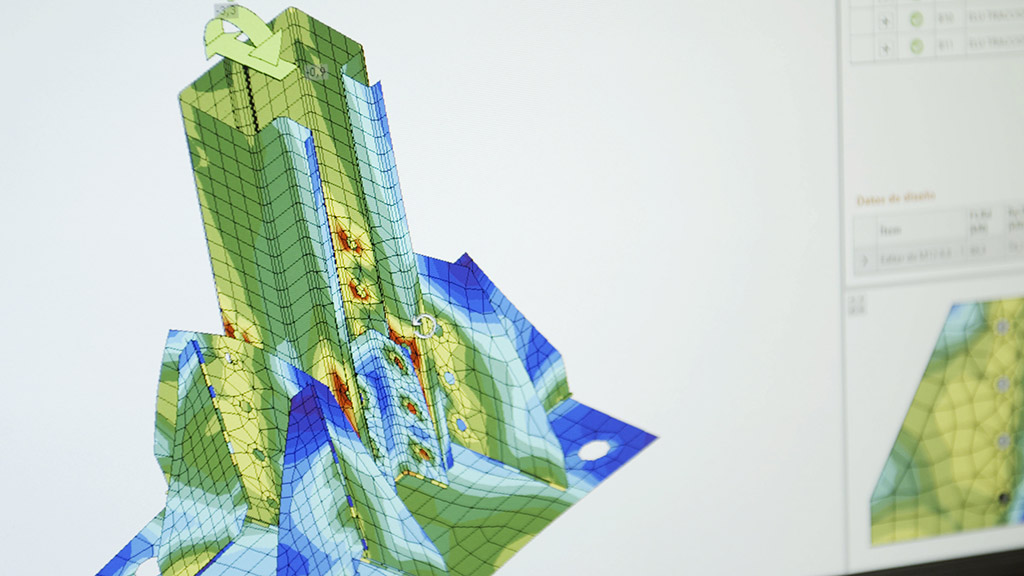

Our primary focus during the project planning and design phase is to identify the storage solution that best fits the unique needs of each client. To achieve this goal, we rely on a team of highly skilled technical experts based at our technological center within the AR Racking headquarters. This team is dedicated to anticipating the evolving needs of every project, ensuring that we deliver solutions that are both efficient and effective.

The technical team at AR Racking initiates the process by thoroughly assessing the specific load requirements of the client. Following this, they meticulously identify the storage system that aligns best with fulfilling these requirements.

Subsequently, engineers conduct a comprehensive analysis of various environmental factors pertinent to the installation site, including seismic activity and meteorological conditions. Finally, when necessary, they seamlessly integrate diverse systems into a unified solution to ensure optimal performance across the board.

Research and innovation are part of AR Racking

Research and innovation are at the core of AR Racking’s philosophy, supported by a dedicated technological center focused exclusively on research and development (R&D). Within this center, our technical team has a specialized space for developing advanced engineering projects and conducting continuous tests to improve product performance.

Our highly skilled team is complemented by automated facilities featuring state-of-the-art equipment, including profile roll forming line machines with continuous cutting processes and laser measurement control, welding centers, and automated painting and packaging processes.

Thanks to these stringent quality standards, AR Racking confidently offers a comprehensive 5-year guarantee covering all manufacturing faults and non-visible defects in our products. Since our inception, we have consistently earned prestigious certifications in environmental stewardship, quality assurance, and operational safety.

Moreover, we ensure compliance with relevant U.S. regulations and maintain membership in leading industry associations, highlighting our commitment to excellence and best practices in the field.