Warehouse Racking Systems | Pallet Racks

AR Racking Inc. is a world-renowned manufacturer of racking systems for warehouses and distribution centres. We offer our top-quality racks in line with all the strictest regulations and standards defined by the MHI and the Rack Manufacturers Institute (RMI) of which we are a full member.

Request a free quote

Why AR Racking US?

AR Racking's industrial warehouse metal racking in the US stands out as a versatile and reliable solution for any company looking to maximize its storage capacity and improve its workflow.

RACKS FOR EVERY COMPANY

Racks for small, medium-sized companies and large multinationals.

Solutions for sectors as diverse as food and beverage, automotive, cold storage, textiles, distribution, construction and mining, logistics and transport, etc.

ENGINEERING AND INNOVATION

We are proud to have a complete team of engineers who design and optimize the rack system to be more efficient.

100% COMPLIANCE WITH DELIVERY DEADLINES

We pride ourselves on delivering on time and on service throughout the country.

GALVANIZED PRODUCT FOR INCREASED DURABILITY

Our racks are made of galvanized steel that will provide the system with superior durability and corrosion resistance.

Benchmark in the US market

AR Racking is a full member of and collaborates with the following U.S. associations, with the goal of creating a logistics and material handling industry with the highest standards of quality and safety for our clients.

Excellent service and on-time delivery

At AR Racking we understand the importance of flawless planning in all processes, as well as smooth communication with our customers. This philosophy not only drives the efficiency of our company, but also contributes to the development and growth of our customers.

We are proud to say that at AR Racking, we maintain a 100% on-time delivery rate across the United States. This exceptional record reflects our commitment to reliability and customer satisfaction. Our extensive network and efficient logistics ensure that your orders arrive exactly when you need them, regardless of your location.

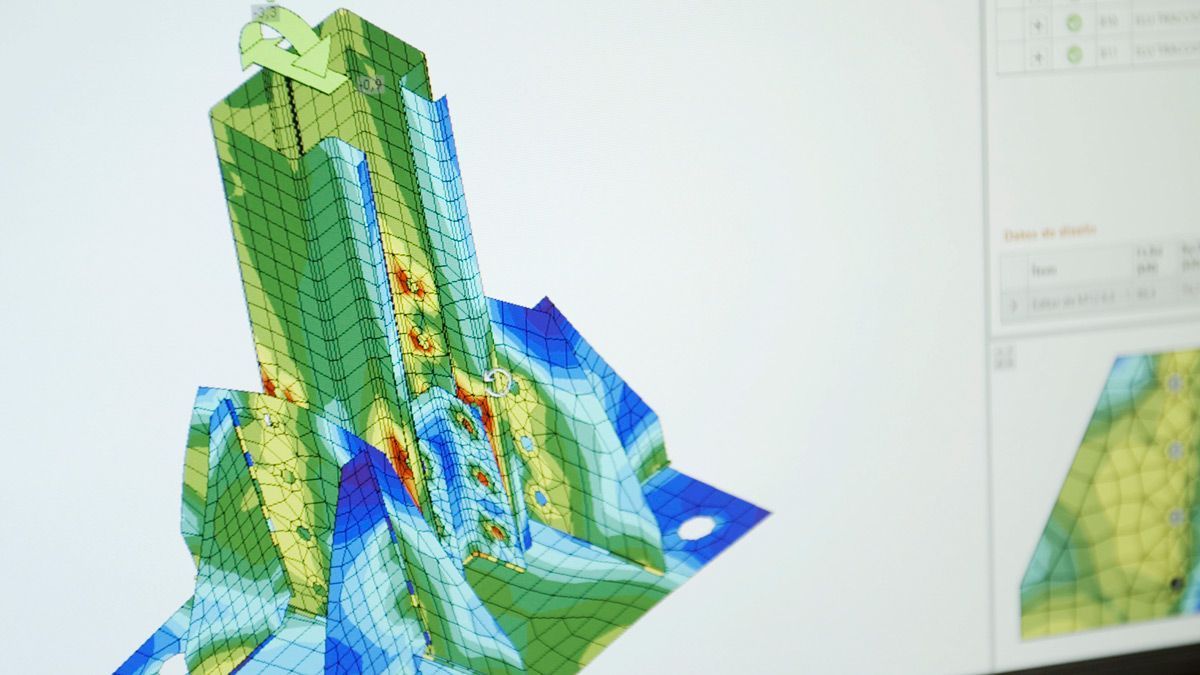

Engineering and efficiency for your warehouse

AR Racking offers a complete customized consultancy service for storage projects.

Find the storage solution which best adapts to the specific needs of the client. This is AR Racking’s main goal during the project planning and design phase. Therefore, it has a highly qualified technical team in charge of anticipating the needs of every project. This team works at a technological centre located in the AR Racking headquarters.

The AR Racking technical team starts by analysing the client’s load needs and then identifies the storage system most suited to meeting the client’s needs. Next, the engineers analyse all the environmental parameters, that is, relative to the area where the structures are to be installed, such as seismic activity and meteorology. Finally, where applicable, they integrate the different systems into one to guarantee optimum performance.

Our highly qualified human team is complemented by automated facilities fitted with state-of-the-art equipment: profile roll forming line machines with continuous cutting process and laser measurement control, welding centres, automated painting and packaging processes.

These quality standards allow AR Racking to offer a comprehensive 5-year guarantee against all manufacturing faults or non-visible defects in its products. Since the beginning of operations, AR Racking has been awarded prestigious certificates in terms of the environment, quality, and operational safety. AR Racking has also demonstrated compliance with those U.S. regulations governing the sector and is a member of its reference associations.

Research and innovation are part of AR Racking US

Research and innovation are core pillars of AR Racking’s philosophy. The company has established a robust technology center dedicated to research, development, and innovation (R&D). This technology center is the heart where we tackle the most complex storage projects for our clients.

AR Racking’s technical area is a dynamic space where advanced engineering projects are developed. Here, engineers and experts work closely together to design innovative solutions that address the most challenging demands in storage and logistics.

Additionally, AR Racking conducts continuous testing to optimize the performance of its products. These tests aim not only to improve quality and efficiency but also to ensure the safety and reliability of every solution we offer.