Racking Systems for Manufacturing industry companies

The manufacturing industry refers to the entire production life cycle, from raw materials to finished products. Some require a large number of raw materials to create the final product, so storage systems in the facilities that produce them are essential for the efficiency of the supply chain process.

It is important to select the appropriate storage method for each situation and space, reducing the time dedicated to the processes and ensuring that they are carried out correctly.

AR Racking offers these types of visibility, traceability and inventory control solutions. This ensures at all times the synchronisation between the warehouse and the production lines.

Storage systems for the manufacturing industry sector

Versatility

In the manufacturing industry sector, there are many differences between companies and products, and different storage systems are needed according to the needs and characteristics of each company. Therefore, one of the main characteristics of storage systems in the industry is their versatility and diversity according to the company.

Storage systems for heavy loads

Generally, the manufacturing industry works with heavy goods stored in pallet unit loads, so warehouse racking systems designed for the storage of pallet loads in their different sizes will be installed.

Combination of various systems

Industrial manufacturing companies may require a combination of several storage systems in their facilities to be able to cover the storage needs of their different product references, in terms of differences in size, cold needs, different supply chain, etc.

Variety of sizes

The storage systems must be designed to store products of different sizes and volumes. Also, depending on the company, they may require specific unit loads that cannot be stored on a standard pallet and that must be stored in custom systems.

Characteristics of the manufacturing industry sector

This industry has been the main economic sector for years in the leading developed countries on the planet.

Transformation into final products

The manufacturing industry is dedicated to the transformation of semi-processed goods or raw materials into final consumer goods, ready for immediate marketing through distributors and other mechanisms that bring them closer to their end customers.

Storage needs

In the manufacturing world, storage needs are infinite. Every facet of organizations can benefit from storage and saving space, as this will make all activities easier.

Recommended Industrial Racking:

Some common storage systems for the manufacturing industry sector are:

Selective Pallet Racking

Selective pallet racking is a very versatile system and also allows immediate access to all the unit loads, facilitating control of the goods.

Very Narrow Aisle Racking

It is a system that is an adaptation of the previous solution, being more compact in a smaller area thus increasing the capacity of the warehouse without having to expand the space.

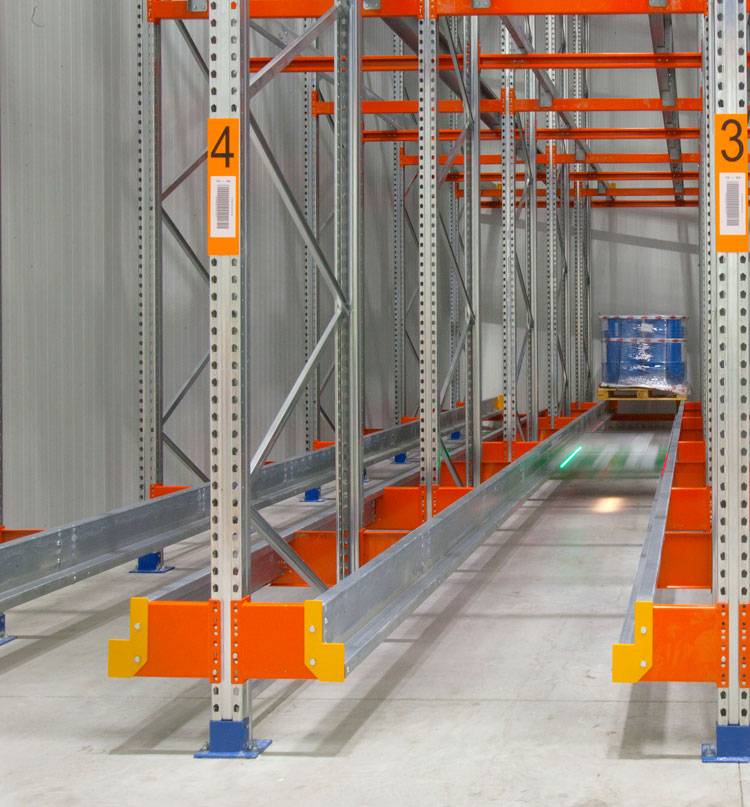

Drive-in Drive-thru Pallet Racking

It is the appropriate pallet storage system when homogeneous products need to be stored with a large number of pallets of the same reference. It can be an interesting option for industrial companies with this type of product.

Pallet Flow Racking (FIFO)

It is a system based on a compact structure in which pallet unit loads slide by means of rollers and a slight slope to ensure perfect product rotation (FIFO).

Pallet Shuttle Racking

This system strengthens the logistics capacity automating the movement of pallet unit loads and allowing inventory control through sensors that count the stored pallets.