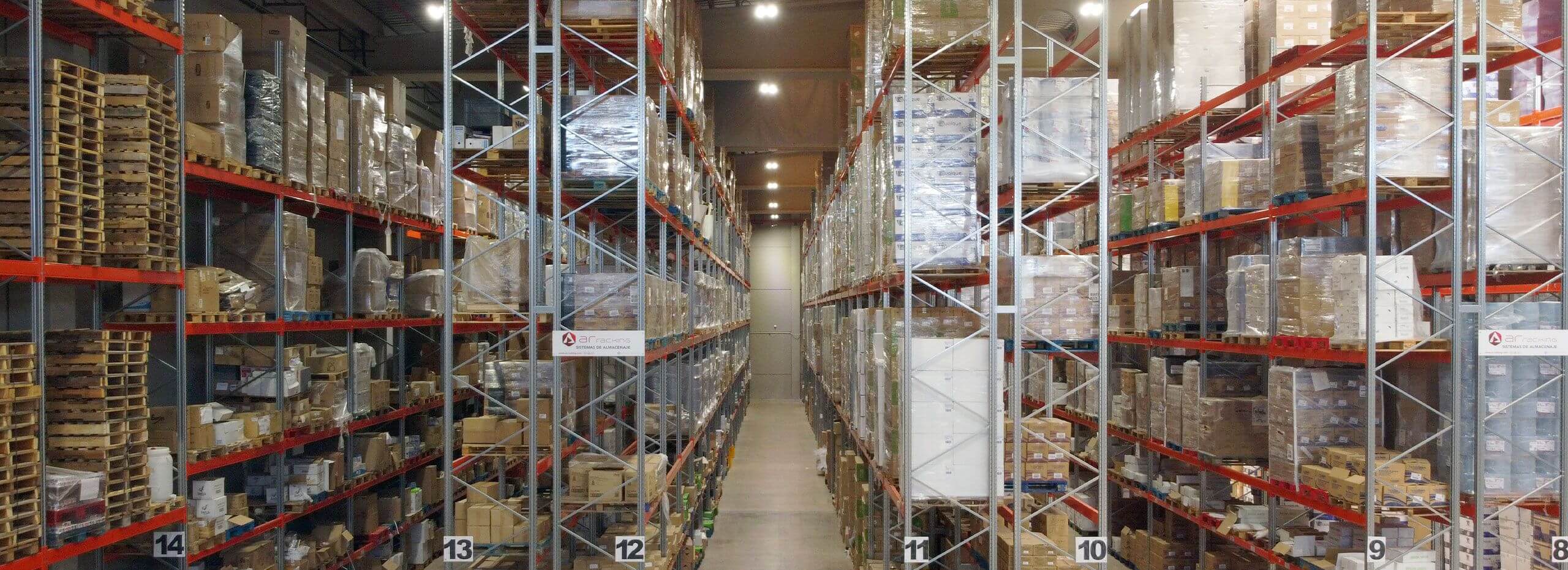

Racking Systems for Logistics, Transport or 3PL companies

Storage systems for the logistics, transportation and storage sector

Versatility

The warehouses of logistics, transport or 3PL companies generally have different storage systems, in order to serve customers with very different needs. The versatility of their warehouses is one of the keys to being able to manage stock correctly.

Stock rotation: Variable

Stock rotation of warehouses in the logistics or 3PL sector is very variable, since it will largely depend on the type of customer they serve. There are logistics companies specialized in sectors with very specific characteristics: freezing, food, e-commerce, etc.

Usual system: Selective Pallet Racking

With these needs, one of the most used storage systems in the warehouses of logistics operators are selective pallet racking systems, which allow direct access to all stored references and therefore give stock management versatility.

Automated storage

These selective racking solutions can also be combined with automated storage systems, which supported by a WMS (Warehouse Management System) allow highly efficient stock management. Automated systems are usually installed in the sector when companies sign long-term contracts with their customers, giving them sufficient time to write off the high investment that automated warehouses entail.

Characteristics of the logistics and transport operators (3PL) sector

The logistics and transportation sector, and specifically 3PL logistics operators, has experienced significant growth and change with the growing trend towards logistics outsourcing.

More services

These operators increasingly have the capacity to assume more and broader services demanded by companies, creating companies that operate under 4PL and 5PL terminology, which, in addition to transportation and storage, perform consulting, auditing and inventory tasks and end up integrating all of the company’s work in the supply chain.

Intensive sector

This sector is intensive in resources such as the need for land, infrastructure and human resources. And with the advancement of technology, it is increasingly supported by technological resources to automate the processes of the distribution chain and equip it with greater safety, control, reliability and traceability.

Recommended Industrial Racking:

Suitable storage systems for the 3PL logistics sector include:

Selective Pallet Racking

Industrial racking system for storage of pallet loads, with great versatility and selectivity for all unit loads. System widely used in logistics and transport operators.

Very Narrow Aisle Racking

Adaptation of the selective pallet racking system for greater optimization of the available space by reducing the work aisles. Direct access is maintained to all unit loads, which means each reference can be stored in a single space.

Automated Storage and Retrieval Systems AS/RS

Given the complexity of warehouse management in this sector, it is common to install automated storage systems that streamline and simplify the process. The design, installation, and implementation of these systems are slower compared to conventional systems.