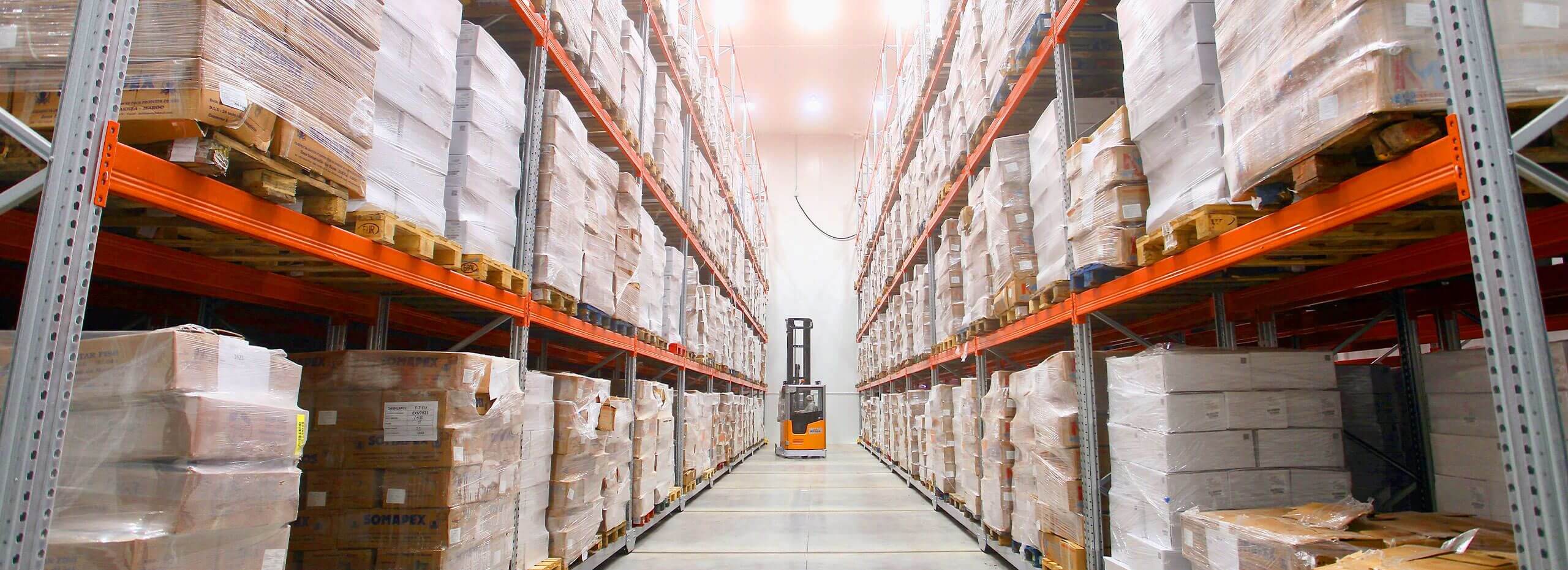

Racking Systems for Freezer and Cold companies

For any company that works with goods that need a controlled temperature, such as the agri-food, chemical or pharmaceutical industries, it is essential to have adequate cold storage for each product characteristic.

Fresh, processed or frozen foods and products must be easily accessible for rapid distribution, since handling, preservation and storage must be carried out at an exact temperature without breaking the cold chain.

Fluctuations in temperature can result in the loss of a product’s properties, its deterioration, or the growth of harmful bacteria. Therefore, high-density storage, efficient cold storage, and proper utilization of warehouse space are critical factors in this industry.

At AR Racking we have extensive experience commissioning controlled temperature warehouses for companies from these sectors.

Storage systems for the cold storage sector

Compact storage systems

The various types of compact industrial racking systems are the usual option for cold storage as they optimize the available space and the volume to be cooled, and therefore also save energy costs.

Smooth stock rotation

Considering that the products that are usually stored in the cold storage sector are perishable products or products with a defined expiration date, it is important to ensure smooth product rotation.

Automated storage

Automated storage systems are becoming an increasingly popular choice for companies in the cold storage sector due to their ability to maximize space utilization and streamline warehouse operations.

Direct access to the unit load: non-priority

Although it will depend on the company’s specific needs, cold stores and freezing chambers do not usually prioritize direct access to unit loads when choosing the appropriate storage system. Compaction of the system is prioritized over selectivity of the goods.

Characteristics of the cold storage sector

Rise of the sector

Current social changes have also boosted the growth of a sector that had already been on an upward trajectory. In addition, the global pandemic had a positive impact on this growth, since it is estimated that consumption of refrigerated and/or frozen products increased by 10% since its start.

Complex facilities

All this means that refrigerated food facilities are complex and require very specialized warehouses. In short, cold storage has been facing short and medium-term challenges for a while, and must now address the new situation, particularly in the food and pharmaceutical sectors.

Recommended industrial racking:

Some common storage systems for the cold storage sector are:

Mobile Pallet Racking (AR Mobile)

This system is ideal for cold stores or freezing chambers due to the reduced volume to be cooled. Furthermore, thanks to the “night configuration” mode, it improves circulation inside the cold stores.

Drive-in Drive-thru Pallet Racking

This storage solution is used in warehouses with cold stores or freezing chambers, due to the need for compaction and space optimization for correct temperature distribution and cost savings.

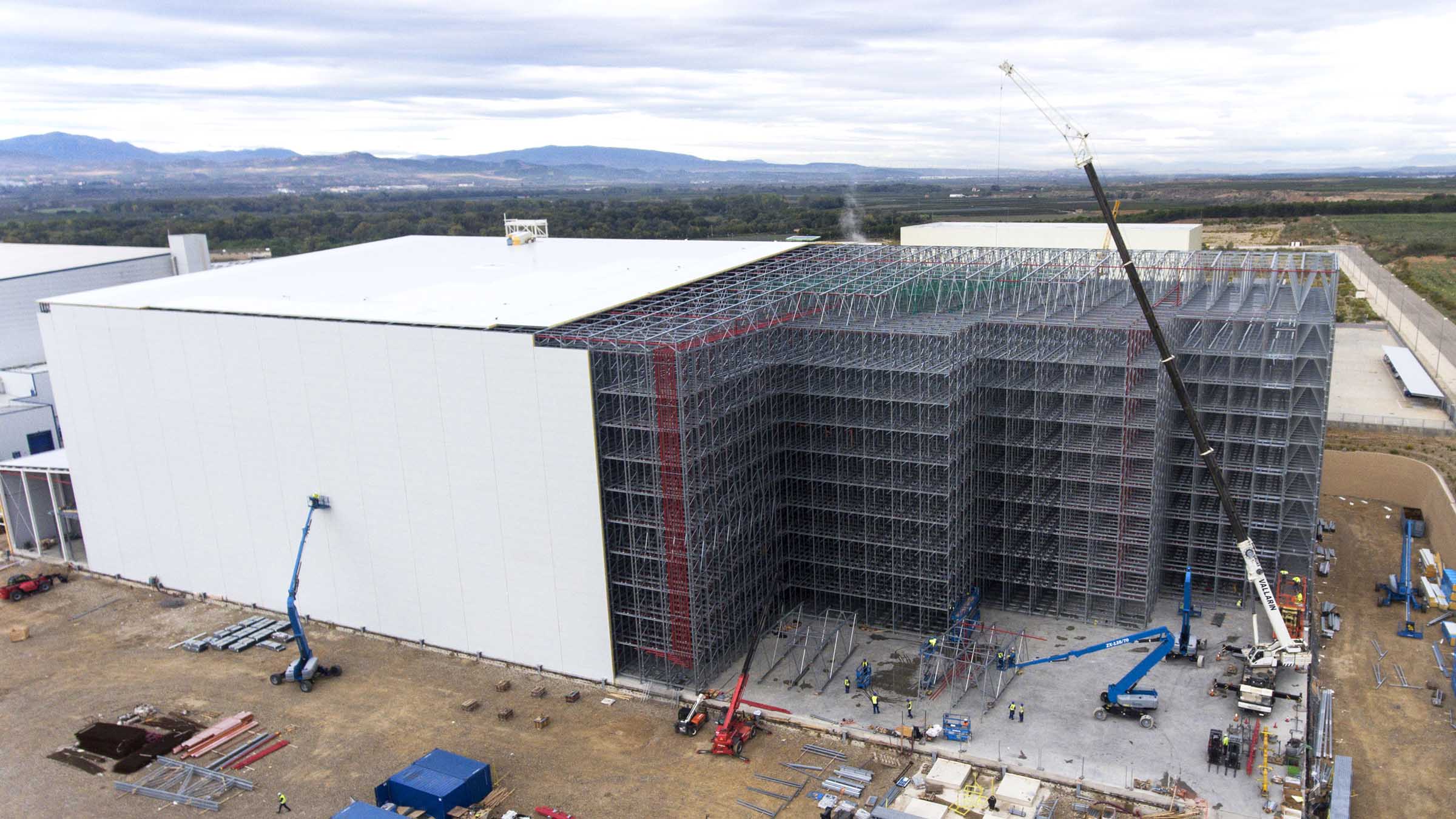

Rack Supported Building

The system perfectly adapts to warehouses that require cold work or work in freezing chambers.