Wide Span Shelving

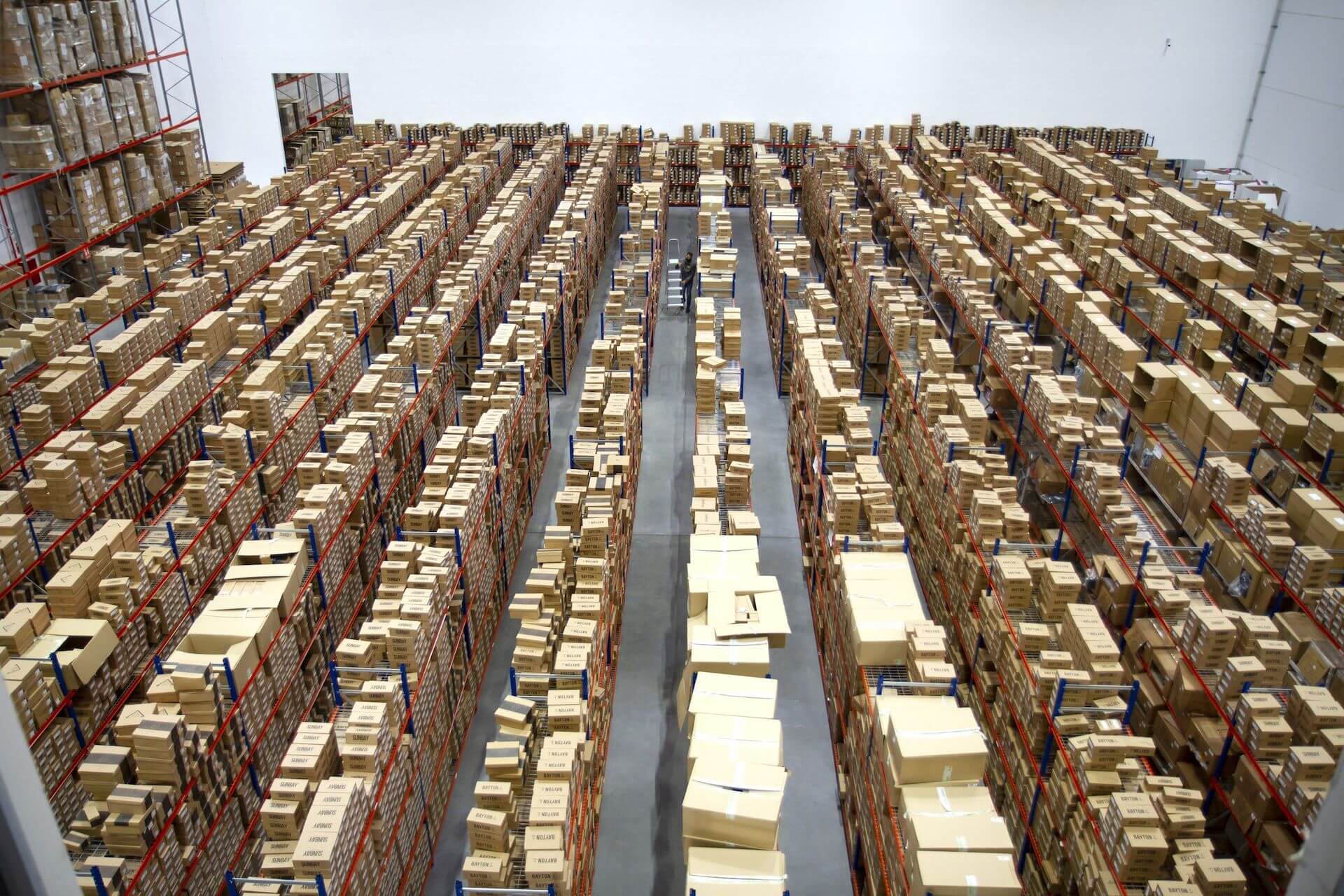

The Wide Span Shelving (AR LS) system permits the manual o picking storage of medium and small materials.

This is a versatile racking that adapts to any type of unit load and facilitates direct and immediate access to stored SKUs.

AR Racking is proud member of these national associations:

![]()

![]()

Widespan shelving systems consist of modular structures with several storage levels.

Its easy assembly and the option to incorporate accessories, such as platforms, make it possible for this racking to increase in height without compromising performance. The design, manufacture and assembly can be customized to suit client requirements and their professional sector.

The Wide Span Shelving is a selective system, enabling all unit loads and SKUs stored to be immediately accessed.

How does it work?

Wide Span Shelving - AR LS

The Wide Span, or Widespan, Shelving picking system is the ideal solution for manually storing small to medium-sized non-palletized products.

The range of accessories and possible configurations allow the system to be modulated and tailored to any type of goods.

Products or unit loads are placed on the racking in an organized way to facilitate manual and direct access by warehouse operators.

The load or manual picking selection process means that operators remove the products from the racking according to warehouse operational needs. This picking action can be done by hand or with the help of machines such as forklifts or picking shuttles.

Although Wide Span Shelving is a manually loaded system, it utilises the full height of the facility, with higher levels accessed using mechanical means (S/R cranes or order-picking trucks) or through walkways located inside the shelving system.

Advantages

Advantages of the Wide Span Shelving storage system:

The main advantages of this system are its accessibility, versatility and cost compared to other more complex or automated types of racking.

- Strong: It is the most robust picking system in the market, enabling mezzanines and multi-tiers to be dimensioned on the shelving system itself.

- High load capacity picking system

- Agile: Wide Span Shelving is easy to assemble and to replace/add components.

- Adaptable: Wide range of bays and shelf depths.

- Direct access to all unit loads stored and visualization of all products.

- Easy adjustment of beam levels every 50 mm.

- Steel or chipboard shelf panels.

- A variety of accessories to suit any storage needs: dividers, garment hanging rails, wire mesh shelves, and more.

- To maximize both floor and height space, miniload and narrow aisle installations aided by order-picking machines can be implemented.

- It is a more economical storage solution compared to more complex or automated storage systems and offers a quick return on investment.

Main applications of Wide Span Shelving Solution

Since it is the most conventional and versatile medium or light loads system, it is also the most widely used among companies.

Listed below are the main types of warehouses and companies for which the AR LS widespan shelving system would be interesting to use:

- Warehouses and distribution centres of e-commerce companies.

- Manufacturing industry for storage of semi-finished components and products.

- Warehouses of food and beverage supermarkets and companies, generally in the final stages of their supply chain.

- Warehouses of pharmaceutical and healthcare companies for storage of medical supplies.

- Retail outlet for storage of products in warehouses close to the sales space.

- Warehouses for spare parts, car parts, paints, etc.

- Warehouses and distribution centres for industrial and electrical supplies and hardware shops.

- Warehouses of any company with medium or light product loads, since it is the most versatile option.

Components and accessories

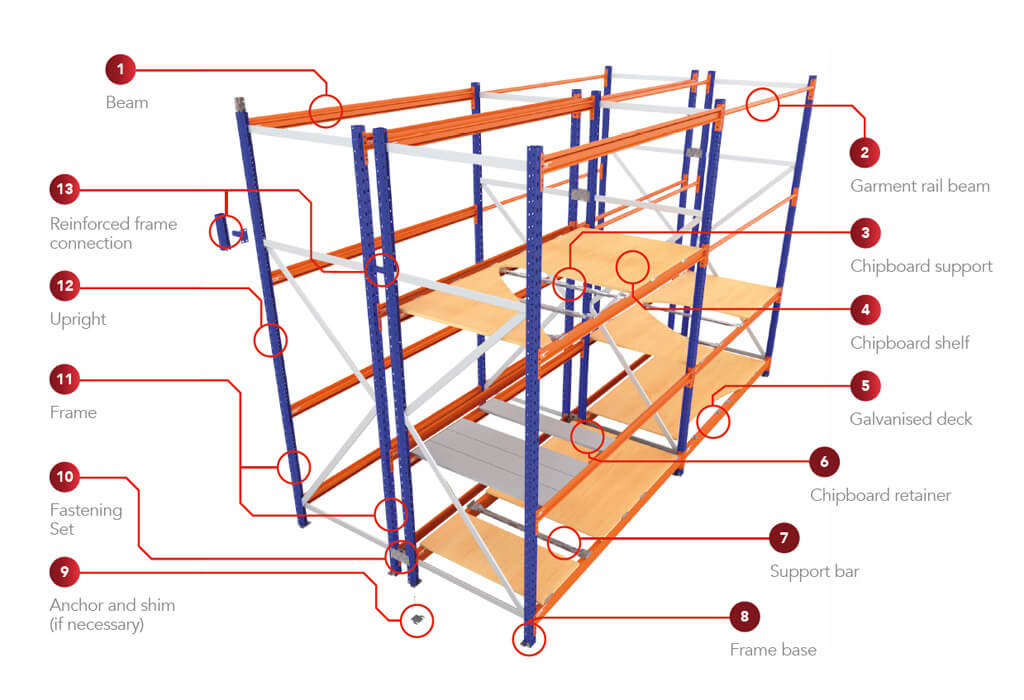

Components of the Wide Span Shelving System

Wide span shelving solutions are made up of several key components, each designed to serve a specific purpose in making product storage and access more efficient.

The primary components and accessories for these systems include:

Frames for Wide Span System

Frames are one of the standard components of manual picking racks.

Frame

The frames are the main vertical components of AR LS widespan shelving.

These frames consist of 2 uprights, their corresponding diagonal braces, upright bases and different fixing elements such as bolts and nuts.

AR Racking has a wide range of racking configurations to meet the storage needs of any company, from lighter loads to heavier loads.

Upright

This is the main component of the frame, providing support and stability to the structure.

The uprights are located at regular intervals along the racking to keep it vertical and withstand the load that it supports. Their design will depend on the load capacity to be supported by the racking.

In AR Racking we have a wide range of uprights of different lengths and widths to adapt to any type of wide span load.

Reinforced frame spacer

The reinforced frame spacer is an accessory that is added to some widespan shelving units to serve as a connection or assembly between frames.

It is an extra reinforcement to the conventional frame spacer for storage systems that have to support heavy loads, with the structure therefore requiring greater strength and stability.

Together, these components create a versatile and efficient storage system that allows companies to effectively access, organize and retrieve products in a widespan shelving environment. The choice and arrangement of these components depends on the specific storage needs of each installation.

Spacer

This is the component used to connect and secure the racking frames to each other, thus forming a solid and stable structure.

These spacers are inserted into the drilled holes in the uprights and then secured to create a solid and secure spacer between the frames.

Anchor and shim

The anchoring elements are responsible for securing the frame supports to the floor.

The shim is a component located under the frame support in direct contact with the floor if it is uneven, to ensure the correct levelling of the entire structure.

This ensures that the racking is perfectly levelled and balanced, which is essential for its safe operation.

Frame support

It is the racking structure component that is located at the base and provides support and stability to the unit.

The frame supports are essential to ensure that the racking stays upright securely and balanced, and are responsible for distributing the weight of the racking and its load on the floor.

The frame supports may include holes or anchor points that allow the racking to be secured to the floor for added stability.

Beams and cross beams for Wide Span Shelving System

Beam

Beams are one of the main structural components of the racking.

They are the horizontal elements that connect to the uprights and act as support for racks or trays on which the unit loads are placed.

They are manufactured in different lengths and widths according to the load capacity required and are adjusted between the uprights to define the horizontal distance between the racks and trays.

They are also responsible for distributing the weight of the loads evenly.

Hanger rod

The hanger rod is a specific component designed for warehouses that require the storage of clothing or textiles.

It is designed to hang clothing instead of placing it on solid racks.

The hanger rod for clothing consists of a horizontal bar installed on the structure joined to the uprights. This bar is height-adjustable to accommodate clothes of different lengths, like coats, dresses, or pants.

Different hooks or brackets designed specifically to hang hangers and prevent them from sliding or falling can be placed along the horizontal bar.

Support bar

They fulfil the same function as the chipboard supports, but are made of steel, being more widely used because of their greater strength and durability.

Chipboard support

These types of additional support bars are installed transversely on the existing beams and are designed to strengthen the structure of the racking by providing additional support between the beams.

This helps distribute the load more evenly and prevents the racks from warping or buckling under the weight of the stored unit loads.

Chipboard supports also provide greater stability and load capacity to the widespan shelving.

Other components of Wide Span System

Wooden rack

Wooden or chipboard racks are a storage platform that is placed on the metal racking structure for the suitable placement of products or materials.

Wooden racks are mainly made of plywood or chipboard planks or medium-density fibreboard, so they are durable and resistant to a variety of loads.

Wooden racks can be fitted to existing metal support bars or rods, enabling their simple installation and adjustment to the racking.

It is a versatile accessory as it can store a wide range of products, from small components, cartons and containers to larger or bulkier items.

Retainer

Metal racking retainers are metal pieces that are fixed to the horizontal beams of the racking.

It is a component designed to keep racks or trays more stable and prevent them and the products they store from sliding or falling.

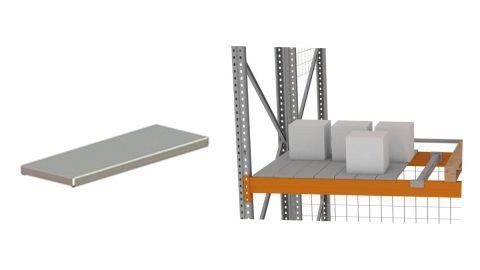

Galvanized tray

Galvanized trays are made of galvanized steel to protect against corrosion and wear. These trays provide a flat, sturdy surface where unit loads are efficiently placed.

Galvanized trays are designed to distribute weight evenly and support different unit loads without deforming.

In addition, the surface of these trays is easy to clean and maintain, especially important in warehouses with food or health products.

Quality and security

Wide Span Shelving systems comply with the strictest national safety standards, and also come with AR Racking’s quality and innovation guarantee.

5-year Quality Guarantee

Our confidence in picking solutions for light and medium loads allows us to provide a 5-year quality guarantee against any type of manufacturing or hidden defect in the components of the main structure.

Component Traceability System

Since 2016, a significant part of our racking components has included a traceability system.

This system gives an identifying marker to the different components, which means we can know and document the origin of each component. This allows us to identify the component, its design and the raw material used in its manufacture.

Fully Automated Manufacture

The production of our industrial racking is fully automated. We use the latest generation profiling machines with continuous cutting process and laser measurement control, welding centres, painting and packaging processes, all fully automated, to guarantee the highest quality standards.

Designs in the R&D&I Centre

The design of the structures of our storage systems is carried out at our technology centre exclusively dedicated to R&D&I activities. We have an advanced engineering development area from which to offer suitable responses to the most demanding logistical requirements.

Tests at Research and Testing Laboratory

With the creation of our Research and Testing Laboratory in collaboration with the University of Mondragón, our technical team carries out continuous testing and analyses of products and materials to improve our racking. We use specialist software to simulate, calculate and research the efficacy of the geometries, and we perform exhaustive structural calculations on the behaviour of the systems already installed in different situations.

Quality certificates of our picking solutions

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Resistance of galvanised steel certificate: UNE-EN ISO 14713-1

- Reaction to fire of galvanised steel: EN 13501-1: 2007

References

With over 26,000 storage projects completed in more than 60 countries, we are leaders in industrial racking solutions. We are proud to have collaborated in the optimization of warehouses with picking solutions for international companies from diverse sectors.

Some notable projects include: