Teardrop Pallet Rack

The Teardrop Racking System is one of the most widely used and standardized racking products throughout the United States.

AR Racking designs and manufactures its teardrop racking systems with this universal design, based on teardrop’-shaped perforations in the uprights.

Therefore, at AR Racking, we offer both teardrop and slotted racking systems in our range, to configure our different storage systems depending on customer requirements.

AR Racking is a proud member of these national associations:

![]()

![]()

This system allows for compatibility with a wide range storage systems available on the market, making it a highly flexible option for companies seeking scalable and adaptable solutions.

The Teardrop racking is a widely used product for racking systems, especially in the U.S. market. Its characteristic design, with “teardrop”-shaped holes, allows for easy installation and adjustment of the beams, optimizing the functionality and efficiency of the racking system.

Its robust structure and versatility make it the ideal choice for a wide variety of industries looking to maximize their storage capacity and adapt to changing market needs.

This system, manufactured by AR Racking, uses beams that are directly inserted into the perforations of the frames, achieving a secure and stable connection with a safety pin. The simplicity of this design facilitates both the initial assembly and later adjustments, allowing the racks to quickly adapt to changes in inventory or operational needs while ensuring stability and safety in the warehouse.

The ease of assembly and adjustability of the racking systems is one of the main advantages offered by Teardrop pallet racking systems. This racking system is economical, efficient, versatile and adaptable to the needs of each customer.

How does Teardrop Racking work?

The Teardrop Pallet Rack system functions through a simple yet highly effective design that enhances ease of use and structural stability. The upright frames have teardrop-shaped holes spaced at regular intervals, allowing the horizontal beams to securely lock into place using specially designed hooks. These hooks fit firmly into the holes with just a press, eliminating the need for bolts or additional hardware.

Once engaged, the beams create a strong framework capable of supporting heavy loads while maintaining stability. The teardrop connection system not only simplifies installation but also enhances safety by reducing the risk of accidental dislodging. Additionally, this design allows for easy height adjustments, so users can reposition the beams as needed to fit different pallet sizes and storage configurations.

The boltless design makes modifications and expansions quick and straightforward, enabling businesses to optimize their warehouse layout efficiently without extended downtime or the need for specialized tools. This flexibility is essential for adapting to changing storage needs.

Advantages of the Teardrop Pallet Racking:

- Standard design: This system is compatible with a wide range of manufacturers in the U.S. market. It supports integration with a variety of components, providing exceptional versatility to fit both existing storage systems and new projects.

- Flexibility: Thanks to its modular design, it is possible to easily adjust the height and configuration of the racks to adapt them to different sizes or merchandise, maximizing the use of the vertical space in the warehouse.

- Compliant with U.S. standards

- Quick reconfigurations: Allows for fast reconfigurations based on changes in inventory or storage volume.

- Versatile application: Suitable for warehouses for almost any industry, from logistics and distribution to retail and manufacturing.

- Stable and safe: The locking system ensures a safe connection and reduces the risks associated with handling heavy loads, minimizing the chances of removal or collapse during operations. This enhances operational safety reducing the risk of accidents.

- Quick and easy assembly: This design ensures a perfect fit and enhances the stability of your racking system.

Teardrop Pallet Rack accessories

It is important to note that with teardrop pallet racks, we can configure virtually any industrial racking system, meaning that the different components and accessories will vary depending on each system.

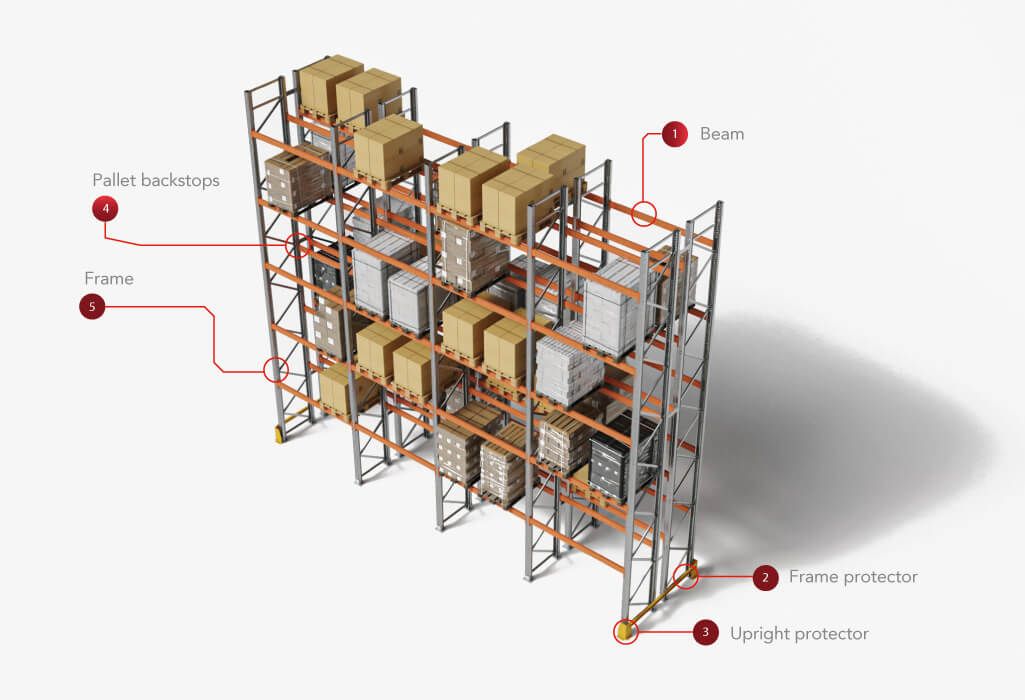

However, the characteristic elements of AR Racking’s teardrop racks are: beams, frames, uprights and protectors.

Teardrop Pallet Rack Frames

Frames are a key part of pallet racking systems. Each frame is made up of two uprights, diagonal braces, baseplates, and fasteners like bolts and nuts.

AR Racking offers a wide selection of frames with a galvanized finish, providing better durability and resistance to tough conditions compared to painted finishes.

Additionally, AR Racking features an identification system for the uprights and beams in their teardrop pallet racking systems. This allows for quick recognition of the design, composition, and all the details that identify the origin of each component, ensuring full product traceability.

The AR Racking traceability system is a major step forward in the company’s push toward automation and aligns with the Industry 4.0 concept.

Teardrop Pallet Rack galvanized uprights

The uprights are the essential components that provide structural support in teardrop racks. These pieces, manufactured by AR Racking from durable steel, are designed to support both the weight of the horizontal beams and the loads stored on the structure.

Their specific feature is the teardrop-shaped holes, with 2” pitch between them, which facilitate the assembly and adjustment of the beams according to the user’s specific needs.

Baseplate

The baseplate is a structural component attached to each upright or column that spreads the load across the floor and allows you to anchor the base to it.

Welded baseplate

The welded baseplate is a component specifically designed for frames with maximum load capacity and height.

Shim

A leveling shim is placed under the baseplate to even out the storage system. This option is used on uneven floors.

Teardrop Pallet Rack Beams

The beams play a crucial role in connecting the vertical frames and directly supporting the pallets or stored goods.

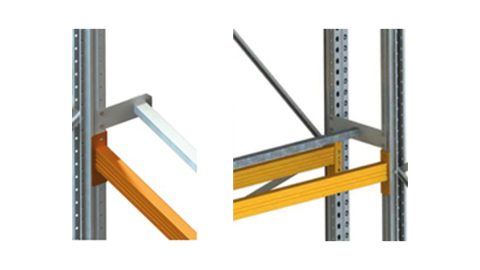

Their installation is quick and efficient, as the beam connectors are designed by AR Racking to fit perfectly into the teardrop-shaped holes of the frames.

This versatility allows the system to adapt to different storage configurations, optimizing available space and facilitating the handling of goods.

Teardrop rack beams include a safety clip on their connectors that acts as a mechanical lock.

These ensure that the horizontal beams remain firmly attached to the vertical frames, preventing accidental movements or disconnections that could compromise the structure.

Racks and panels

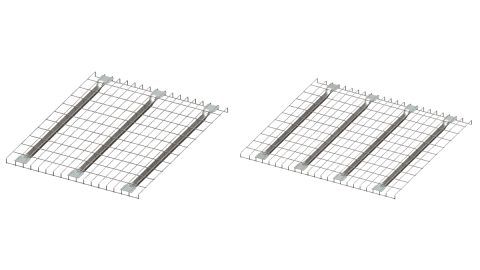

Mesh panel (protection and fall-arrest)

Metal mesh panels are components used as load levels to support goods on pallets and their various loads in teardrop pallet racking systems.

The rectangular mesh is secured to support bars, providing rigidity to the structure. The unit sits on AR beams without requiring additional fixings. Mesh panels can also be installed for picking applications, customized to the dimensions and weights of the products each customer needs.

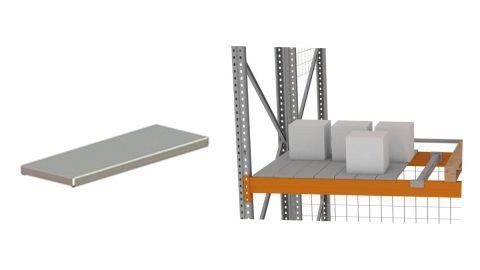

Galvanized tray

AR Racking’s galvanized metal trays are designed to fit directly onto the beams without requiring additional fixings.

This accessory for teardrop racks is used alongside orange Z beams for picking. The trays are available with either a smooth or grooved surface.

Chipboard panel

Chipboard panels, also known as boards, can be used in various ways with teardrop racks.

They can be placed directly on the beams with the help of retainers at the ends for added stability. Additionally, support bars must be installed, depending on the load, to provide extra support for the unit load.

Support bars and container support

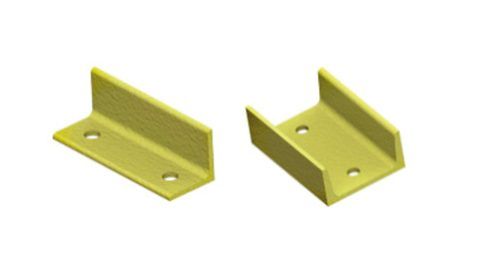

TM55 support bar for wood

TM55 support bars for wood are specifically designed to hold 22 mm thick wooden boards or chipboard, ensuring the wood is flush with the height of the beam. The dimensions and thickness of the support bars can be customized to meet the requirements of each project.

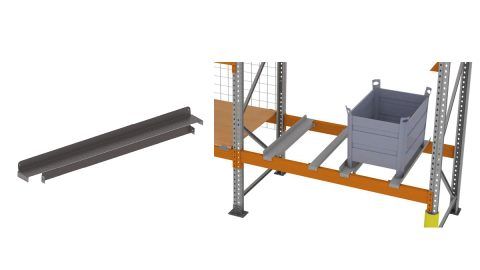

T451 support bar

T451 support bars are structural components installed crosswise on the beams, allowing pallets to be securely placed on them. They offer an added layer of safety to help prevent pallets from falling in specific situations.

TNP84 Raised Support Bar

TNP84 “Top Hat” raised support bars are designed to allow forklift access under the unit load. They are ideal for storing loads without pallets or bottom runners, providing an efficient solution for easy loading and unloading.

Container support

Container supports are used when the unit load consists of containers with legs at their ends. The system consists of two supports arranged crosswise on the beams to securely hold the containers in place.

Prevention and safety measures

There are several accessories available to enhance installation security, including pallet backstops, protection meshes, and protectors.

Teardrop Pallet Rack backstops and protection meshes

Single and double pallet backstop

Single and double pallet backstops are safety features for teardrop pallet racks, designed to prevent pallets from falling due to improper handling.

They consist of a metal profile mounted on two arms, which are bolted to the sides of the uprights or columns.

The single backstop is used for single-sided runs, while the double backstop is designed for double-sided runs.

SINGLE PALLET BACKSTOP | DOUBLE PALLET BACKSTOP

Kibi pallet backstop

This is a structural element arranged crosswise on the beams in double runs.

Its purpose is to alert and prevent pallets from falling in the event of improper handling of the unit load.

Floor pallet backstop

Floor pallet backstops differ from other types of backstops.

They are fixed to the floor to serve as a warning and to help retain unit loads placed directly on the floor. They are available in both single and double configurations.

SINGLE FLOOR BACKSTOP | DOUBLE FLOOR BACKSTOP

Protection meshes

Protection meshes are mesh panels used as protective elements on both the base and sides of teardrop racking. They serve as a safety feature to prevent the unintended displacement or falling of unit loads.

These meshes can be made of either nylon or metal. The flexibility of the nylon mesh allows it to fully recover its original shape after any incident.

NYLON MESH | WIRE MESH

Teardrop Pallet Rack Protectors

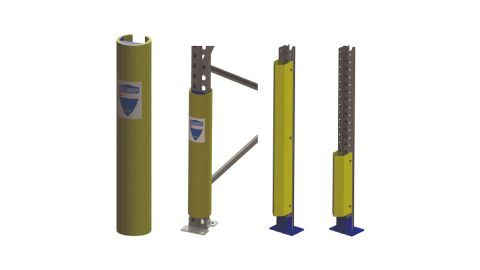

Upright or column protector

They are installed on each of the external uprights of the racking system.

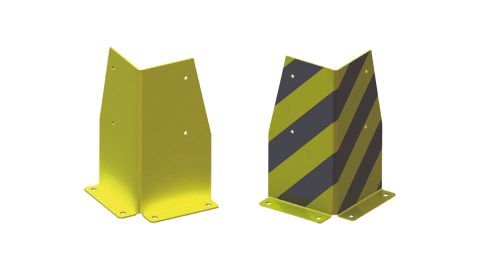

Corner protector

Corner protectors are an alternative when upright protectors cannot be installed.

They protect the external uprights, are fixed to the floor, and are made of sheet metal.

Their design can be either smooth or grooved, depending on the requirements.

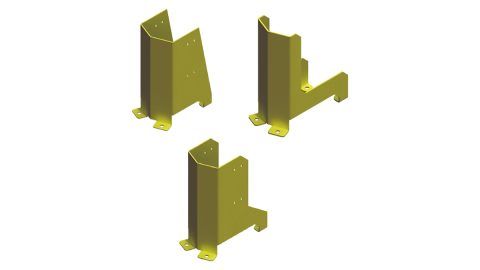

Upright reinforcement protector

Upright or column reinforcement protectors are used in teardrop racks when additional protection is needed for the upright at a height higher than that covered by the upright protector.

These protectors can be made of either sheet metal or plastic, and they are fixed directly to the upright itself.

Side frame protector

Side frame protectors safeguard the lower side areas of teardrop pallet racking.

These “C”-shaped protectors are placed on the outer frames, where impacts are more likely. They are typically paired with upright protectors for added protection.

There are also side wood protectors available, which serve the same purpose.

Drum and cylinder supports

The AR Racking supports for drums or cylinders fit directly onto the beams.

Their purpose is to facilitate the storage of special cylindrical loads, primarily drums.

They consist of a set of two elements that fit into the beams, supporting both the front and rear of the drum.

Two “L”-shaped welded elements on each unit secure the cylindrical load in place on the rack.

This specially designed support ensures that loads can be handled safely while stored.

Coil racks

Coil racks make it easy to store materials wound on coils, like cable, rope, cloth, and more.

These side supports require a central metal spindle that allows the coils to rotate.

The side coil support is mounted to the sides of the frame, with two parallel parts needed for proper function.

Coil racks add versatility to the teardrop system, allowing it to be used with other storage systems.

Teardrop Pallet Racking signs

Markers

Markers are rectangular metal plates attached to the outer parts of teardrop pallet racks to label the different aisles of the installation with letters and numbers.

The plate is mounted on the upright in various ways, depending on the specific requirements.

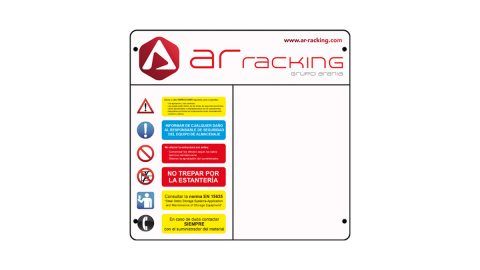

Load warning notice

The load warning notice is a component mounted in visible areas of the structure to provide personnel with important information for the safe use of the storage system.

It is typically attached to the outer frames of the installation.

The notice includes safety warnings, details about the storage system, load capacities, and contact information for the manufacturer and distributor.

Vinyl load label

The vinyl load label is an identifier that shows the load capacity of each beam.

This helps ensure the safe use of the storage system, minimizing risks and preventing confusion during loading and unloading.

The vinyl label is printed and adhesive, and it is directly applied to the beam of the teardrop pallet racking.

Quality and security of Teardrop Pallet Racks

Teardrop pallet racking solutions comply with the strictest national safety standards, and also come with AR Racking’s quality and innovation guarantee.

5-year quality guarantee

The reliability of our teardrop pallet racks solutions means we are able to offer 5-year quality guarantees against all types of manufacturing or hidden defects in the components of the main structure of our racking solutions.

Pioneering component traceability system

Since 2016, our teardrop racking components have included a component traceability system.

With this system, the various above-mentioned elements have an identifying mark, which means being able to trace and document each component from origin without needing to have the package label, and therefore, knowing which piece it is, its design and what raw material has been used in its manufacture.

100% automated production

Our industrial racking production process is fully automated: it incorporates state-of-the-art profiling machines with a continuous cutting process and laser measurement control, welding centres, painting and packaging processes, all automated, which guarantee the highest quality parameters.

Designs in R&D&I Centre

The structures of our teardrop racking systems are designed in our exclusive R&D&I technology centre and supported by the advanced engineering project development area, helping to provide a suitable response to the most demanding logistics requirements.

Tests at Research and Testing Laboratory

With the creation of our Research and Testing Laboratory in collaboration with Mondragón University, our technical department continuously tests and analyzes products and materials to improve our teardrop pallet racks. It simulates, calculates, and researches (using specialized software) the efficiency of the geometries and performs full structural calculations on the behavior of the systems already installed in various situations.

Teardrop Pallet Racking quality certificates:

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007

- Selective Pallet Racking Quality Certificate:

- EN 15512

- EN 15620

- EN 15629

- EN 15635

- FEM 10208