Mobile Pallet Racking

Mobile Pallet Racking (AR Mobile) is a system where the pallet racks are placed on chassis or mobile bases guided through fixed tracks on the floor.

AR Racking is proud member of these national associations:

![]()

![]()

The base of this type of racking is equipped with an electrical motor and remote push-pull elements allowing the racks to move along the tracks in order to open only one forklift access aisle.

Mobile pallet racking is a high density storage system, providing simple access for conventional forklift pallets. Its versatility permits its adaptation to both the load type and the type of forklift.

A series of technical and organizational protective measures are in place to ensure that the movement of the shelving does not pose a risk.

The features of the AR Mobile racking system make it the ideal storage system for cold storage and deep-freeze units, thanks to the reduction in the total volume to be cooled.

How does Mobile Pallet Racking - AR Mobile work?

The AR Mobile Bases System for pallets is designed to compact the shelving facility and significantly increase warehouse capacity.

This is a high density system as the individual access aisles found in conventional racking systems have been eliminated, leaving just one aisle.

In the Mobile Pallet Racking, the aisle to be accessed for work is automatically opened using electric motors and moving components fitted on the base of the racking. The operator gives the order to open via the remote control.

The operator is responsible for sending from the remote control or main control the order to open the racking which has 2 main operating modes:

- In the “automatic or opening operating mode”, with the compaction of the racking blocks one after the other, it is possible to open space for the work aisle in which you want to load or unload the unit load.

- In the “night setting mode”, all the aisles of the installation open automatically and uniformly having the same but reduced width between each other, thus favouring the improvement of air circulation inside the cold rooms.

Since this is a compact system, the surface area occupied by the storage solution can be minimized. This is ideal when floor space costs are high or when there’s a need to increase storage capacity without expanding the footprint.

The use of the Mobile Pallet Racking system decreases the total volume of the installation, making it essential for refrigerated and freezer chambers at medium and low heights.

The savings in energy help to quickly pay off the installation.

Mobile Racking advantages

The advantages of mobile pallet racking arise from its capacity for maximum compaction of the structure, while maintaining direct access to all unit loads.

- Industrial mobile racking adapts to any space, weight, or size of the goods, and is compatible with other automatic or conventional storage systems.

- Efficient use of space. High density storage system, i.e., the same space with a higher storage capacity

- Energy savings: control of lighting and reduction of space to be cooled. Only the aisle that is open is lit. Once the rack is fully loaded, the lighting for that row is automatically switched off.

- Direct access to any stored pallet, implying a saving in time.

- Perfect for Refrigeration chambers or deep-freeze units thanks to the reduced volume to be cooled. It also permits air circulation. In the “night-time configuration” mode, all the aisles of the installation open automatically and uniformly, with an identical but reduced width between each one. This helps to improve air circulation within the refrigeration chambers.

- Reduction of times for manoeuvre and displacement with the forklift, using the remote control to select the aisle required for work.

- Allows picking work to take place at lower levels.

- The forklift truck type used in selective pallet racking zones can still be used here.

- Reduced operating costs thanks to excellent use of space.

Main applications of Mobile Pallet Racking

Mobile pallet racking, as an excellent compaction system, will be of optimal application for customers with the following storage needs:

- Warehouses whose main need is to optimize the available space, either because it is small or because of its high price per square metre.

- Warehouses where direct access is necessary to each unit load.

- Storage of goods that do not have a high turnover.

- Storage in cold rooms or freezing chambers. It is the ideal system for these situations due to the high density of the system and the correct temperature distribution that it allows with night mode.

Components and accessories Mobile Pallet Racking

The base structure of mobile pallet racking is based on selective pallet racking, i.e., a simple structure consisting of frames, beams and accessories.

What makes this system unique is the addition of specific elements that allow the racking to move.

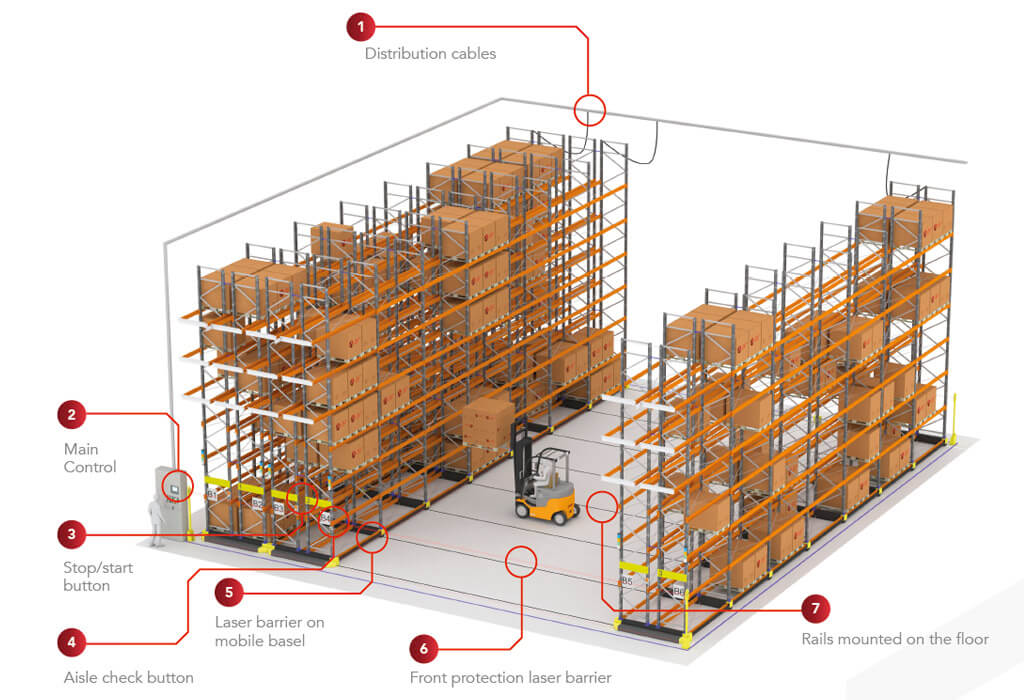

Its specialized components for operating as mobile racking include a main control, laser barriers on the mobile base, front protection, floor rails, and buttons for starting and checking aisles.

The mobile pallet racking system is particularly well-suited for cold storage and freezer rooms, both at low and medium heights

Principal components of mobile pallet racking are:

Rails installed on the floor

Rails built into the floor of the warehouse for the movement of the shuttles that support the structure of the mobile bases.

Front protection laser barrier

Safety laser device located on the front that provides information to the main control on the position of each block of racks to prevent potential risks or obstacles.

Laser barrier on mobile base

Safety laser device with the same risk prevention objective as the front protection, but located on the base of the racking.

Aisle check button

Safety device to ensure each work aisle generated with the compaction of the structure.

Start/stop button

Complementary control button to the main control to order the start or stop of any of the mobile pallet racking blocks.

Main control

Mobile pallet racking operations centre, which combined with the remote control, registers, orders and processes the different operating modes.

It has various control buttons and a screen that displays the information.

Distribution cables

Electrical distribution wiring system which is responsible for supplying electricity to the electric motor of each block of racks and therefore closing the electrical circuit to ensure the operation of the system.

In addition to the specific elements, the basic components that make up the structure are:

Frames

The frames are one of the basic components of the structure and consist of 2 uprights, their corresponding diagonals, baseplates and fixing elements.

Unlike selective pallet racking, in mobile pallet racking the frames will not be anchored to the floor, but rather to shuttles that ensure the movement of the structure.

Galvanized upright or column

The upright or column is the main vertical component of the frame and is galvanized.

Baseplate

The baseplate is a structural component joined to each upright that distributes the load and enables its anchoring to the shuttle.

Beams

Beams are the horizontal elements which support the load and join the frames together.

They have connectors which fit into the drill holes of the upright and provide an extremely firm and safe joint system, increasing their load capacity.

AR Racking’s wide range of beams includes a wide variety of types, lengths and load capacities to adapt to the specific needs of each warehouse.

Quality and security Mobile Pallet Racking

Mobile pallet racking systems comply with the strictest nacional safety standards, and also come with AR Racking’s quality guarantee.

100% automated production

Our mobile pallet racking basic component production process is fully automated: it incorporates state-of-the-art profiling machines with a continuous cutting process and laser measurement control, welding centres and automated painting and packaging processes, which guarantee the highest quality parameters.

Designs in R&D&I Centre

Our mobile pallet racking systems are designed in our exclusive R&D&I technology centre supported by its advanced engineering project development area, allowing us to respond suitably to the most demanding logistics requirements.

Tests at Research and Testing Laboratory

The Research and Testing Laboratory developed in collaboration with the University of Mondragón provides our product area with the appropriate tools for the testing and analysis of our mobile pallet racking systems.

It simulates, calculates and researches the efficacy of the geometries, and makes full structural calculations on the behaviour of systems already installed.

5-year quality guarantee

The quality reliability of our mobile pallet racking solutions means we are able to offer 5-year guarantees against all types of manufacturing or hidden defects in the components of the main structure of our racking solutions.

Pioneering component traceability system

Since 2016, the uprights and beams of our mobile pallet racking components have included a pioneering traceability system in the sector.

With this system, the various above-mentioned elements have an identifying mark, which means that each upright and beam can be traced and documented, and that information is therefore available on which component it is, its design and what raw material has been used in its manufacture.

Quality certificates of the Mobile Pallet Racking system:

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007

Our projects and customers speak for us. With more than 26,000 projects carried out in over 60 countries, we have satisfied customers from various sectors: food and beverage, automotive, distribution, electronics, pharmacy and cosmetics, industrial and transport and logistics.

Below are some of the mobile pallet racking projects we have made public in recent years: