Double Deep Pallet Racking

Double Deep Pallet Racking is a storage system that is halfway between selective pallet racking systems and compact storage systems.

AR Racking is proud member of these national associations:

![]()

![]()

In double deep pallet racking, the unit loads are stored mechanically by forklifts that move along the aisles arranged in parallel to the racking systems.

In this system, the pallets are stored at two depths, thus achieving higher storage density, while access to the pallets remains simple and relatively quick. Unlike selective pallet racking, in double deep pallet racking, the operator does not have direct access to all the pallets stored.

Double deep pallet racking must be used with special forklifts prepared for this type of system, equipped with telescopic forks or with an especially designed pantograph mechanism to correctly access the second pallet.

It is a highly efficient and robust system, with easy assembly and adjustment of load levels. Additionally, it functions as selective pallet racking and is perfectly adapted to goods of varying weight or volume.

How does Double Deep Pallet Racking work?

Double deep pallet racking systems increase the available storage space, by simply storing the pallets at two depths instead of one as with the selective or adjustable pallet racking (APR) system.

The 2 pallets are accessed from the same aisle, reducing the number of aisles by half compared to the selective pallet racking system.

In short, double deep pallet racking increases warehouse storage density by reducing aisles and increasing storage locations.

As direct access is only available for front unit loads, this double deep system for managing LIFO (Last in, First out) stock is recommended for storing identical or high rotation products, with more than one pallet per reference.

Advantages of Double Deep Warehouse Racking

- Increase in storage capacity compared to selective pallet racking.

- Access to the pallets continues to be simple and relatively quick, maintaining 50% immediate accessibility and reasonable rotation of goods.

- System with a good use of all the available locations, generally above 80-90%.

- Intermediate system between an adjustable or selective racking system and a high-density compact system.

- LIFO (Last in, First out) system, where the last pallet deposited on the racking will be the first one to leave.

- More efficient system, which eliminates unnecessary aisles and increases the use of available space.

- Double deep pallet racking systems adapt to any type of unit load.

- As with selective pallet racking systems, the assembly and disassembly process and replacement of components is quick and simple.

- Saves time and effort in the handling of unit loads, generating fast stock rotation.

- The design of double deep pallet racking enables its reconfiguration or extension according to the storage needs that arise.

- High level of safety thanks to the variety of accessories that it can incorporate.

- The uprights and frames of AR Racking’s double deep pallet racking systems are pre-galvanized and include an innovative traceability system.

Main applications of Double Deep Racking for Pallets:

Double deep pallet racking systems, due to their similarities to the selective pallet racking system, are a very versatile and adaptable solution to a wide range of storage needs.

However, their greater storage capacity and reduced accessibility to the unit loads make their application especially recommended for warehouses with the following characteristics:

- Warehouses for products with more than one pallet per special storage unit.

- Homogeneous or identical product warehouses.

- Warehouses with stock with a medium or long-term useful life. It is not recommended for very perishable products since double deep pallet racking is a LIFO type system.

- Warehouses with a high-performance stock management system where restricted access to all the pallets is not a problem.

- Warehouses in which a balance is required between the accessibility or selectivity of the unit loads and the increase in storage capacity.

Components and accessories of Double Deep Racking Systems

Double deep pallet racking has the same structure as selective pallet racking, only that its layout is different, so the racking components are the same or very similar.

Double deep storage systems will therefore consist of a simple structure made up of beams, frames and other accessories such as support bars and supports.

This system also has safety elements such as frame and upright protectors, fall-arrest meshes, reinforcements and pallet backstops.

Double Deep Racking Frames

Frames are one of the key elements of double deep pallet racking. They consist of 2 uprights, their diagonal braces, baseplates and fixing elements such as bolts and nuts.

AR Racking Inc. has a broad range of frames with a galvanised finish, which means greater durability and resistance to adverse conditions with respect to the painted finish.

AR Racking’s uprights and beams also feature a pioneering traceability system that immediately identifies the design, composition, and origin of the component. This ensures full product traceability.

Galvanized upright

The upright is the key part of the frame and is galvanized.

Its dimensions will depend on the storage needs of the installation, to be chosen from the range of upright sections and lengths for double deep pallet racking.

Baseplate

The baseplate is a structural element joined to each upright which distributes the load and makes it possible to secure the structure to the floor.

Welded baseplate

The welded baseplate is designed for frames of greater load and height.

Shim

Component situated under the baseplate to level the storage system. It is an accessory for use in warehouses with uneven floors.

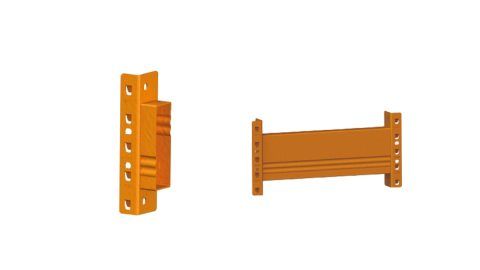

Beams for Double Deep Pallet Racking

Beams are the horizontal components of double deep pallet racking, which support the unit loads and join the frames together, and which are located parallel to the work aisle. They have connectors which fit into the drill holes of the upright.

The connectors designed by AR Racking USA create an extremely firm and secure joint system formed between the beam and upright, increasing the load capacity and the duration of the system.

Orange 2C Beam

The orange 2C beam consists of 2 “C” shaped profiles welded together. Wide variety of lengths, widths and resistances to adapt to each storage need.

Orange Light Beam

Light beams are used in light load storage cases. These beams can be used for any type of pallet loads or for picking levels.

Hot Dip Galvanized Beam

Hot dip galvanized beams for double deep pallet racking have a zinc bath that improves their corrosion resistance.

They are therefore suitable for very aggressive environments, as is the case in warehouses for chemicals or with very saline environments.

Pre-galvanized standard pin

The safety pin is an individual element that is placed on the connector that joins the beam to the upright to prevent accidental displacement of the beam.

It is an approved component that enhances the safety of the storage system. It is a reliable and simple method that can be inspected with the naked eye.

This pin is compatible with all beams in the AR Racking Inc. range. The hot dip galvanized beams use a red pin to enable their control from the floor.

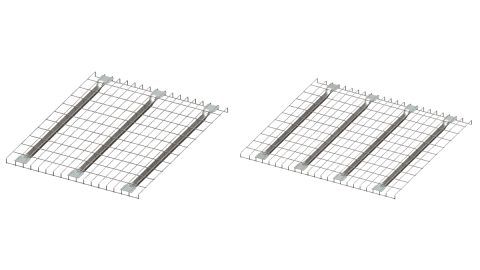

Racks and panels

Protection and fall-arrest mesh panel

Metal mesh panels are components used to support the goods of the unit loads on double deep pallet racking.

The rectangular mesh is attached to the support bars giving the structure rigidity. They are placed on the AR beams without the need for extra fixings. The meshes are also adaptable to picking solutions.

Chipboard panel

Chipboard panels can be used in various ways in AR PAL double deep pallet racking.

They can be placed directly on the beams adding retainers at the ends for better fixing. In case of a heavy load, add support bars to support the unit load.

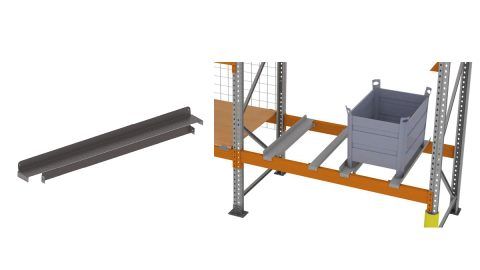

Support bars and container supports

TM55 Support Bar for wood

TM55 support bars are designed for being able to place on their upper level 22mm thick wooden boards or chipboard, with the wood flush with the height of the beam.

T451 Support Bar

T451 support bars are horizontal components crossly arranged on the beams and which enable the placement of pallets on them.

They provide greater safety and prevent the potential falling of pallets from the double deep pallet racking.

TNP84 Raised Support Bar

The TNP84 “Top hat” raised support bars are designed to simplify the process of the entry of the forks and forklifts under the unit load.

They are used in facilities with unit loads without pallets or bottom runners and are the ideal solution for simplifying their loading and unloading.

Container support

Container supports are an element used to store containers with legs at their ends.

They consist of a set of 2 supports crossly arranged on the beams that allow containers to be easily deposited.

Preventive and safety measures of Double Deep Racking

There are various complementary elements that enhance the safety of the installation, such as pallet backstops, the protection meshes and protectors.

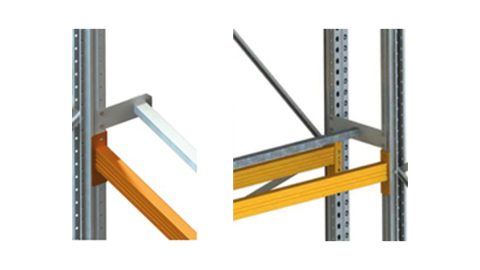

Pallet backstops

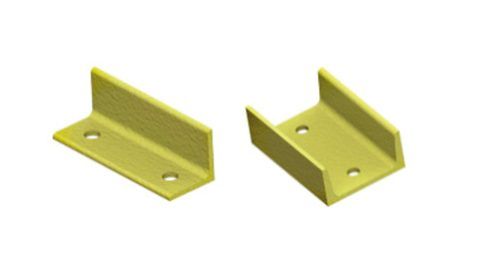

Single and double pallet backstop

They are preventive safety backstops for double deep pallet racking. Their objective is to prevent the pallet from falling due to an inappropriate manoeuvre.

They consist of a metal profile set on top of 2 arms bolted to the sides of the uprights.

The single backstop is used for single runs, and the double backstop is used for double runs

SINGLE PALLET BACKSTOP | DOUBLE PALLET BACKSTOP

Kibi pallet backstop

This pallet backstop is crossly arranged on the beams in double runs and its function is to prevent the falling of the pallet in case of an inappropriate manoeuvre with the unit load.

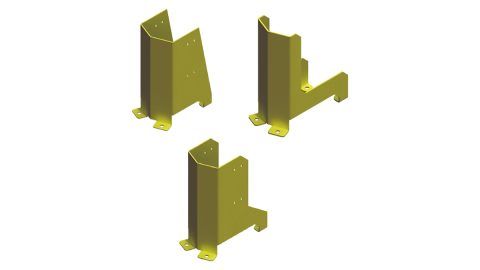

Floor pallet backstop

The single or double floor pallet backstops are fixed to the floor of the warehouse and serve as a warning and retention for the unit loads.

SINGLE FLOOR BACKSTOP | DOUBLE FLOOR BACKSTOP

Double Deep pallet racking protectors

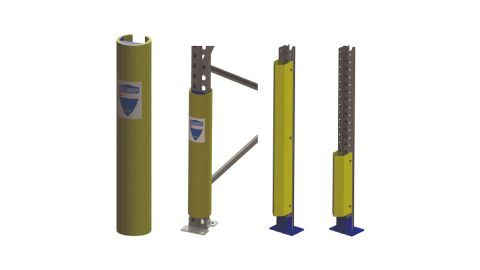

Upright protector

Upright protectors are installed on the external uprights of the racking and their function is to protect the installation from the impacts of forklifts.

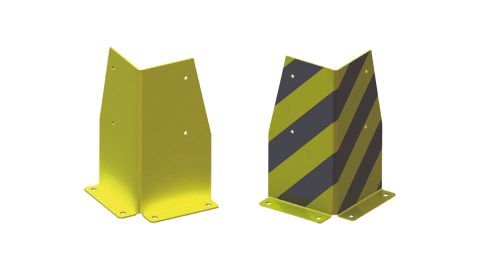

Corner protector

Corner protectors are an alternative option when it is not possible to use upright protectors. It is a sheet metal component, fixed to the floor and designed to protect the external uprights.

Upright reinforcement protector

Upright reinforcement protectors are installed in double deep pallet racking systems at a higher height than that of the upright protector. They can be made of either sheet metal or plastic, and are fixed to the upright.

Side or frame protectors

Side or frame protectors are C-shaped protections located on the outer frames of the double deep pallet racking.

They are joined to the upright protectors to create a more effective protection.

Pallet Racking signs

Markers

Markers are rectangular metal plates that are placed on the external parts of the racking, fixed to the upright, to indicate the different aisles of the installation.

Load warning notice

Load warning notices are components fixed in visible places of the installation, generally on the outer frames, and which include information for correct use of the storage system.

Vinyl load label

The vinyl label is an adhesive, placed directly on the double deep pallet racking beams, that indicates the load capacity of each beam.

Quality and security Double Deep Pallet Racking

Double deep pallet racking systems comply with the strictest European safety standards, and also come with AR Racking’s quality and innovation guarantee.

5-year quality guarantee

Our confidence in the reliability of our double deep pallet racking solutions means we are able to offer 5-year quality guarantees against all types of manufacturing or hidden defects in the components of the main structure of our systems.

Traceability system

Since 2016, our double deep pallet racking systems have included a component traceability system.

The system consists of an identifying marker, which means knowing and having documented each component from source without needing to have the package label and therefore knowing the exact component, how it was designed or what raw material was used in its manufacture.

Fully automated production.

The production process of our industrial racking systems is fully automated: it incorporates latest generation profiling machines with continuous cutting process and laser measurement control, welding centres, painting and packaging processes, all fully automated, guaranteeing the highest quality parameters.

Designs developed at the R&D&I Center

The structures of our storage systems are designed in our technology centre dedicated to R&D&i activities, as well as in collaboration with the advanced engineering projects development area, which allows us to respond appropriately to more demanding logistical requirements.

Tests at Research and Testing Laboratory

At our Research and Testing Laboratory created in collaboration with the University of Mondragón, our technical area continuously tests and analyses products and materials to improve our double deep pallet racking systems.

It also simulates, calculates and researches the efficacy of the geometries, and makes full structural calculations on the behaviour of the systems already installed in different situations.

Double Deep Pallet Racking quality certificates:

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007

- Pallet Racking Quality Certificate

- EN 15512

- EN 15620

- EN 15629

- EN 15635

- FEM 10208

As pallet racking experts with more than 26,000 storage projects implemented in over 60 countries, we are fortunate to have collaborated in the optimization of the warehouses of major international companies from various sectors: food and beverage, automotive, distribution, electronics, pharmacy and cosmetics, industrial and transport and logistics.

Listed below are some of our double deep pallet racking projects: