Miniload AS/RS Automated Warehouse

The Mini-load System, Free Standing AS/RS for cases, is the optimal solution for the storage of light and small unit loads with high stock turnover ratios such as cartons or trays.

This system allows you to sort, locate and retrieve cartons that are on the warehouse shelves, thus reducing the time and cost of the order preparation process.

This system uses automated stacker crane mechanisms to handle loads, offering high performance and reduced carton storage and handling times and stored elements.

AR Racking is proud member of these national associations:

![]()

![]()

Miniload systems are known for their compact, high-density design, which allows them to maximize the available space and height in the warehouse by reducing the number of aisles. This is especially beneficial for optimizing storage in facilities with limited space.

Miniload systems are therefore ideal for storing a large number of products. They use racking and storage trays designed to maximize height space, enabling a large volume of products to be stored in a small area. It is therefore possible to manage a wide variety of SKU and adapt to different shapes and sizes of loads, aiding inventory management and product handling.

They also guarantee the assurance and preservation of products that need to be stored in cold and frozen environments, controlling the warehouse temperature.

How does it work Miniload AS/RS?

Miniload is a warehouse automation system based on metal shelving elements for picking designed so that the load is automatically handled by stacker cranes. They are therefore created to optimize inventory management and facilitate the efficient retrieval of stored products or materials. The use of stacker cranes also minimises waiting times and improves goods handling precision.

Stacker cranes collect cartons from their location and present them at the order picking location or deliver them directly to the order preparation conveyor.

This type of automatic stacker crane also transports the cartons to the corresponding worker, and when he/she finishes his work, he/she returns them to the shelves, placing the cartons on angular gantries screwed to the side of the upright, allowing the stacker crane platform to be placed under the load for removal.

Main Mini load AS/RS Systems advantages

- Product-man system in which the operator does not move.

- Optimization of warehouse space, both in height and width.

- Increased productivity and efficiency. Reducing the margin of error by eliminating human errors, automating the inflow and outflow of goods, maintaining constant inventory control and having the ability to operate uninterrupted, results in increased productivity.

- Cost savings. Reducing the time required to carry out logistics processes, together with improvements in productivity and extending the useful life of the structure, will also result in lower costs.

- Time saving. By eliminating the need for operator displacement, the time spent in the order preparation process is significantly reduced, thus improving the customer experience.

- Space saving. Miniload systems can significantly increase available warehouse space. This space is therefore better used, since a height of up to 30 metres can be reached.

- Flexibility to combine and adjust to other storage systems, with the possibility of adding picking levels or adapting to different temperatures.

- Minimizes load handling errors.

- Allows a daily and perpetual inventory of stored products, providing information in real time. It has computer software that records all stored items and manages inventory in real time.

- Security. Workers do not have to move through the warehouse aisles, thus avoiding possible accidents resulting from falling goods or being run over.

- It guarantees the ideal preservation of the product thanks to the installation of cold stores or freezing chambers ensuring a controlled temperature inside the warehouse.

Main applications of Automated Picking Systems

Miniload systems are an optimal solution for companies with bulk order preparation processes, so the following types of main companies would use this storage solution the most:

- Health sector, since they store a large volume of products in a small space with controlled temperatures.

- Companies with high volumes of documentation and files.

- Spare parts and maintenance in sectors such as plumbing and electricity.

- Distribution companies that store and distribute products with a high turnover.

- In sectors where high volumes of order preparation at a time are required, such as the textile sector.

- Companies that need to store their products in cold stores or freezing chambers. It is an ideal option for operating at low temperatures.

- Companies that need to optimize picking processes.

Components and accessories of Miniload Automated Warehouse

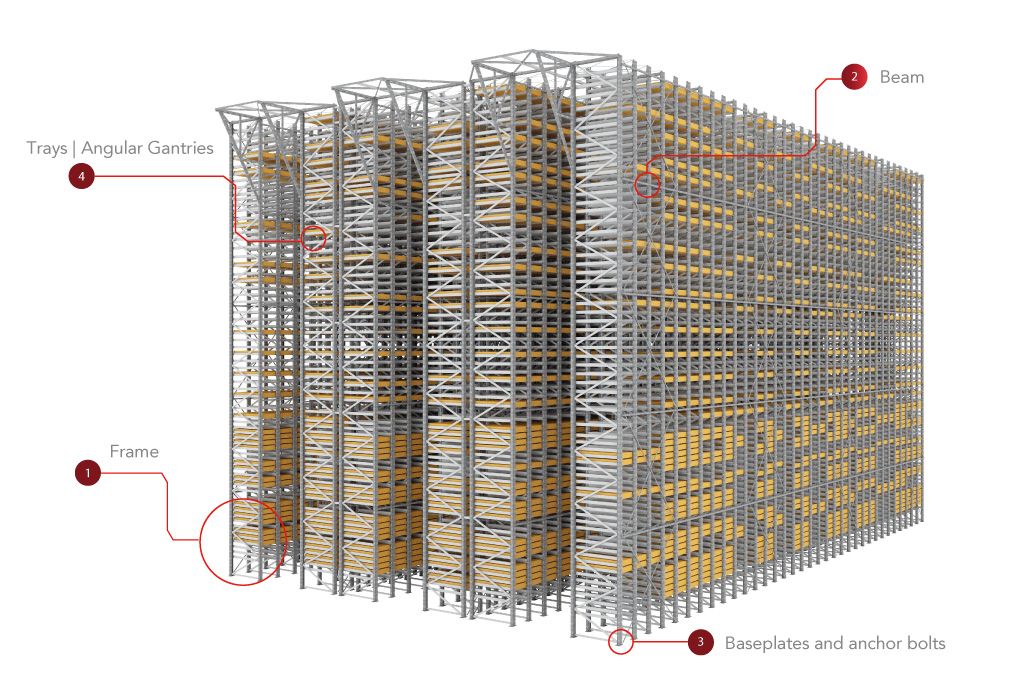

The Miniload storage system consists of a series of essential components for efficient operation, including the frame, beams, feet, anchors, and trays or angles.

However, these are just the basic elements of the structure. In a Miniload storage system, there are many additional components that can be integrated based on the customer’s specific needs, allowing for optimal customization to different types of warehouses and unique logistical requirements.

Main components of the Automated AS/RS Storage Totes

Frame

It is an essential element to provide the stability and functionality necessary for automated and efficient product handling.

Baseplates and anchor bolts

Baseplates and anchor bolts guarantee the stability, safety, correct functioning of the system, and minimize risks and possible damage.

Beam

Beams provide structural support, define storage configuration, facilitate automated access and help optimize the warehouse space.

Trays | Angular Gantries

They are fundamental components used to store and transport products within the system. They provide efficient, robust and adaptable storage for products within the system.

Quality and security of Miniload Automated Storage and Retriveral System

Miniload systems comply with the strictest National safety standards, and also come with AR Racking’s quality and innovation guarantee.

5-year Quality Guarantee

Our Mini-load System solutions for light and medium loads allows us to provide a 5-year quality guarantee against any type of manufacturing or hidden defect in the components of the main structure.

Component Traceability System

Since 2016, a significant part of our racking components has included a traceability system.

This system gives an identifying marker to the different components, which means we can know and document the origin of each component. This allows us to identify the component, its design and the raw material used in its manufacture.

Fully Automated Manufacture

The production of our industrial racking is fully automated. We use the latest generation profiling machines with continuous cutting process and laser measurement control, welding centres, painting and packaging processes, all fully automated, to guarantee the highest quality standards.

Designs in the R&D&I Centre

The design of the structures of our storage systems is carried out at our technology centre exclusively dedicated to R&D&I activities. We have an advanced engineering development area from which to offer suitable responses to the most demanding logistical requirements.

Tests at Research and Testing Laboratory

With the creation of our Research and Testing Laboratory in collaboration with the University of Mondragón, our technical team carries out continuous testing and analyses of products and materials to improve our racking. We use specialist software to simulate, calculate and research the efficacy of the geometries, and we perform exhaustive structural calculations on the behaviour of the systems already installed in different situations.

Quality certificates of the Automated Picking System

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007