The full implementation of a project with various industrial processes requires precise coordination between a wide range of human and technical resources. The essence of turnkey projects is that in addition to the customer obtaining a satisfactory final product, they experience a complete purchase and delivery process, as well as a tailored, personalised and highly efficient service.

In recent years, turnkey projects have been the especially adopted formula for high-volume orders in industrial sectors, which also include industrial storage and industrial racking for warehouses. This is a complex but easy to understand process if three basic concepts are taken into account:

What is the objective of turnkey projects of warehouses?

The turnkey project, sometimes also known as a turnkey contract, is an agreement between the customer and the service/product supplier (or contractor) in which the latter undertakes to comprehensively manage all the project phases from the start or the preliminary phase to the final delivery of the contracted project. The contractor will be responsible for ensuring not only the delivery of the product or service (in this case, the installation of industrial racking systems), but also and absolutely every step of the project in all its phases.

The purpose of warehouse turnkey projects is to offer a comprehensive service to the customer (or contractor), so they do not have to worry about anything other than the supervision of the project to check that it is being implemented according to the previously agreed terms.

What should the turnkey concept include in an industrial storage project?

The main factors addressed in turnkey projects are: project design, execution deadline, price and payment method, performance guarantees and the law that governs the contract.

Turnkey industrial storage projects comprise several phases:

Analysis of the need:

This is the initial assessment of the customer’s need who must communicate to the storage system supplier what they are looking for, the space possibilities, the characteristics of the company and its operations, the flow of goods, etc. This will allow the contractor to be able to carry out an analysis of the customer’s need and prepare a custom proposal for a storage solution or the sector in question.

Advice on solutions and formalisation of the contract:

After the initial contact between the customer and contractor, the supplier must propose to the customer the solution that best suits their needs. The proposal is communicated after a detailed study of the situation, considering all the technical variables (deadlines, planning, quality, etc.) and logistics. If necessary, several alternatives will be proposed. In this way, the customer will be able to carefully assess the project and establish a relationship based on transparency.

The supplier must advise the customer in every aspect related to the execution of the project, present itself as a trustworthy partner, and always offer a project that gives the customer greater competitiveness. The customer, with all the information to hand, will decide which is the most suitable proposal and proceed with the formalisation of the contract.

Design and calculation of structures:

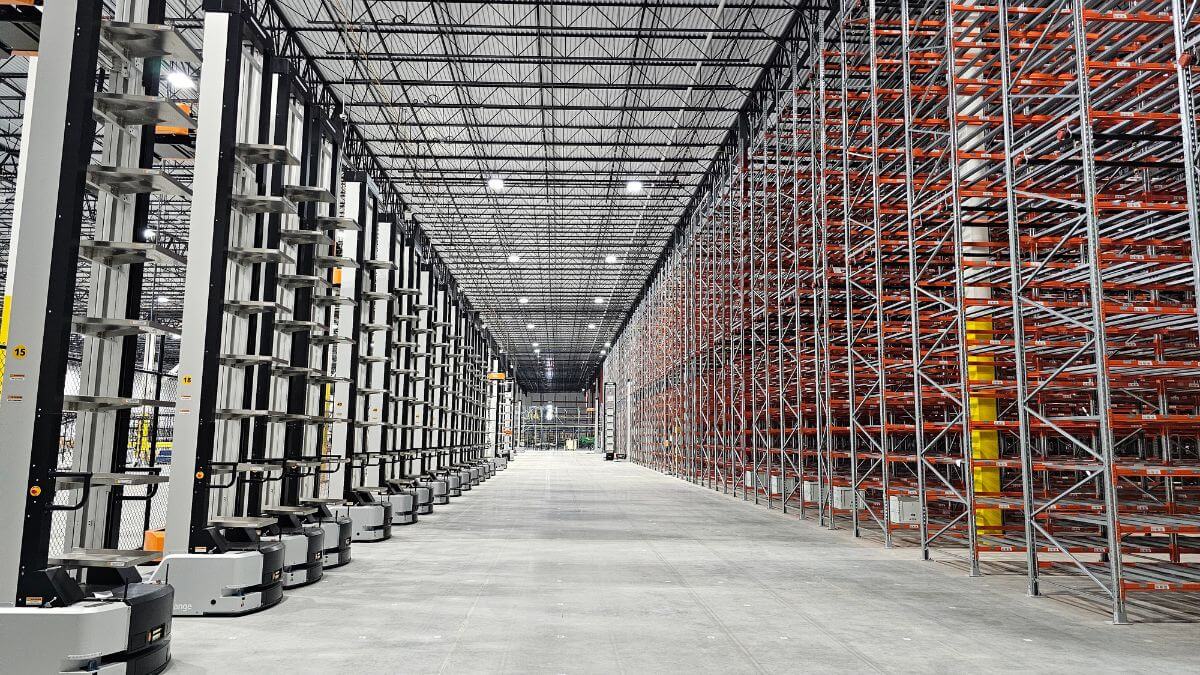

This is the phase in which the industrial process actually begins. The engineering team will design and calculate the industrial racking to be fitted in the industrial unit, warehouse or distribution centre. After identifying the most suitable storage system, environmental factors that potentially affect the structure will be analysed for the subsequent design, calculation and manufacture of the racks.

Production planning and monitoring:

This is the structure installation stage, which will be implemented in various phases in the warehouse. The project phases will be supervised continuously to check that the deadlines agreed with the customer are being met. Coordination between project managers, administrative and financial staff, operations managers, technicians, etc. will be key to the execution of the project.

Quality control and logistics:

Quality control must be carried out in all phases of the project, especially in the industrial racking manufacturing process, where laser measurement, welding, painting, finishing and packaging controls are performed. However, quality must also be guaranteed in compliance with the standards of regulatory bodies.

Planning of the installation and its execution:

Once it has been verified that the product designed and manufactured or acquired from other suppliers strictly complies with the customer's requests and what is agreed in the project meets the required quality parameters, the installation and assembly phase begins. This is a demanding phase, involving many people and with the added pressure of meeting deadlines. Every detail must be supervised before closing a project.

What are the advantages of a turnkey project for a warehouse?

From the customer’s perspective, the advantages of a turnkey project are as follows:

Budget control:

The customer will know from the start the approximate total cost of the warehouse project and will only have to worry about making the financial transactions indicated with a single supplier, greatly streamlining processes and avoiding risks of losing control.

Direct contact:

Industrial projects, whatever their nature, involve many contacts. Such a situation can slow down a project, lead to mistakes that ultimately affect execution and take up time that could be better devoted to other projects. Turnkey projects ensure a dual direct relationship between customer and contractor, with a faster and more efficient result.

Set delivery time:

The deadlines are set in the prior agreement. As all the processes are managed in a single company, a lot of time will be saved, since design and manufacturing times are established from the start and will not depend on third parties.

Greater knowledge of the process:

Direct communication with the company responsible for executing the warehouse project means the customer is closer to the process and can monitor its progress first-hand, allowing them to intervene or modify any aspects that they consider necessary or that do not comply with the request.

Personalised after-sales service:

If a problem of any kind arises after the delivery of the turnkey project, the customer will be able to interact directly with the supplier without having to contact or coordinate with different companies or personnel responsible. This will enable faster and more efficient incident management.