A well-organised warehouse is essential to ensure that a company’s logistics processes are productive, effective and as agile as possible. Improving the performance of a warehouse or distribution centre is not simple as it requires sound continuous planning and depends on many elements overall, not just the storage systems.

An ideal planning for each warehouse provides exceptional benefits for the business, such as fully maximising the space, time saving in all the processes, reduction in and optimisation of costs achieving greater benefit and good organisation of the inventory.

Unfortunately, good warehouse management is not always achieved. A list is set out below of typically commented errors that hinder the correct organisation of the warehouse.

Common warehouse management errors

Lack of awareness of product location

This problem arises when the warehouse is not well organised and when warehouse personnel do not know the location of products through lack of knowledge or incorrectly labelling products with their identification code. This will delay the entire process including the customer delivery time.

Lack of space due to poor warehouse design

When the inventory or stock is stored poorly, without storing each product in its place, and when the aisles are not respected, leaving everything untidily in a corner, problems arise. This is normally due to an incorrect planning and design of the warehouse layout when it was created.

Inventory problems

Sometimes warehouses suffer a stockout for failing to have highly requested products at all times. It is essential to guarantee the customers’ goods to ensure their satisfaction and the delivery times.

Poor human resources management

Sometimes warehouse workers do not perform the processes correctly, simply because they are poorly organised, they are unfamiliar with their activities or they are overloaded with work.

6 tips for the organisation of a warehouse

These errors can be avoided by considering, among others, the following tips or recommendations to help manage the warehouse correctly.

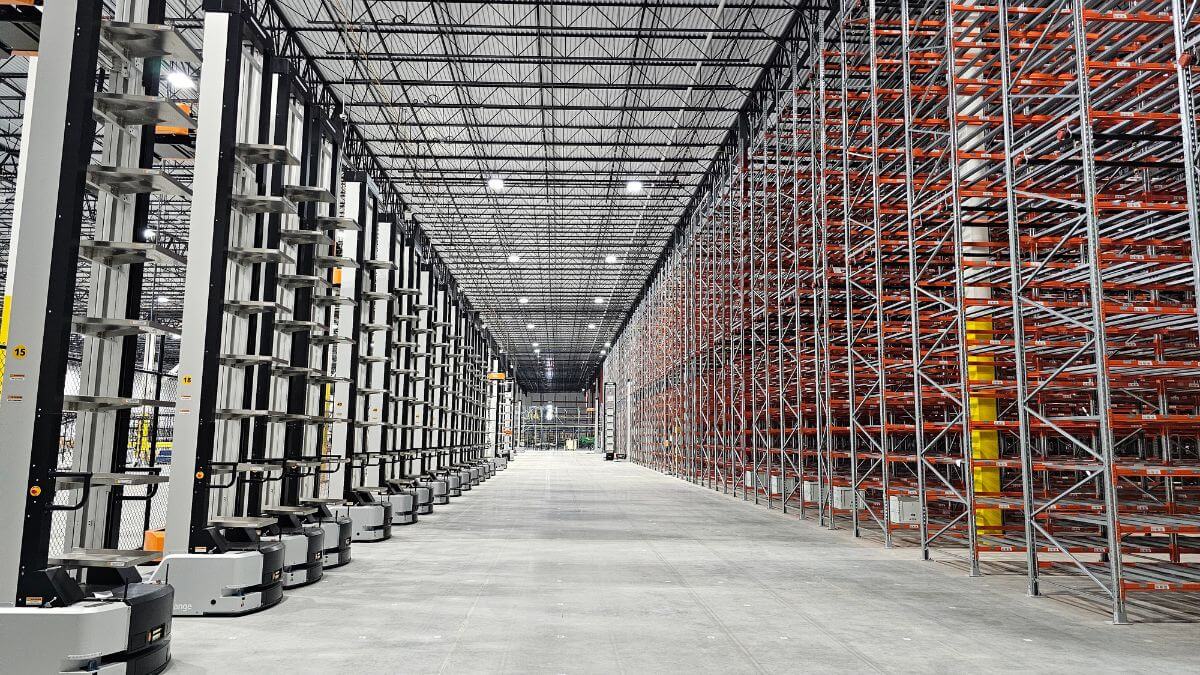

Planning and design of the warehouse space

Warehouse design is the main characteristic that needs to be considered, as it includes the full equipping of the facilities:

The space must be fully and effectively exploited, creating more efficient routes for the personnel and stock, thus saving time and costs.

Warehouse operating personnel must be suitably qualified and perform all the processes efficiently, avoiding risks to goods and the warehouse itself.

The support equipment will be essential; the forklifts must be appropriate for the different types of racking, as well as the barcodes, the pallet shuttles and many other elements that help favour and optimise flows.

Organise the stock by demand and rotation

In a warehouse some products are requested more than others, or simply demand varies seasonally. We need to know the inventory with the highest rotation at all times, as it will be vital to organise it in different ways, placing these products closest to the shipment area to save time in the process and to avoid a stockout when customers request the goods.

Location of products and their labelling

Each reference must be correctly labelled with its identification code, and placed in its location. To identify each product without any errors, the warehouse must be well organised. We therefore need to define and differentiate each area, respecting the actions carried out in each one. It is important to maintain this organisation over time.

Establish safety procedures and tasks for employees

Just as the inventory must be correctly organised, so must workers’ tasks, together with the safety regulations that must be respected at all times. Each worker will perform their respective duties, but always be flexible to any modifications required by each situation.

Warehouse safety is essential, so workers must perfectly know how to ensure this in order to work more efficiently. For this they will complete awareness courses, as the safety protocol must be known by every person who enters the warehouse.

Use Cross Docking in the warehouse

The objective of this technique is for the product to be stored the least time possible. When the goods reach the warehouse, they will be transported directly to the picking area for shipment, without passing through the warehouse stock. This will help save storage space and time, improving order delivery time and reducing costs.

Implement quality controls

Achieving good customer satisfaction is the most important point to consider, so if the orders are error-free their satisfaction will increase.

Before any order leaves the warehouse, it is essential to perform quality controls to avoid errors or a stockout.

To save time, we need to perform these controls in each stage of the logistics process, from product collection, picking and packaging through to shipment.

All the above-mentioned points are vital for good organisation of warehouses. Each has its own different needs, but all require constant planning so that the processes are truly efficient and everything works correctly.