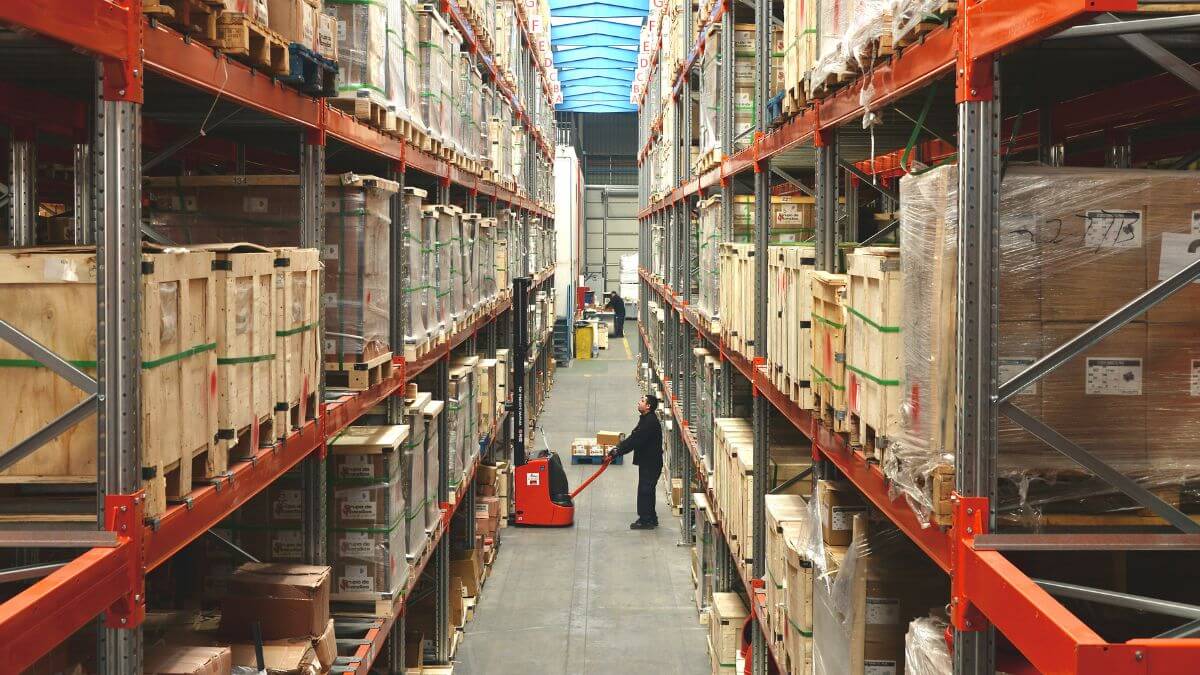

Retrofitting is an increasingly common practice in warehouse management. It consists of the updating and modernisation of existing facilities to improve their efficiency and adaptability to new demands. This article explores in detail the concept, advantages, comparisons with other options, and the planning required to successfully retrofit a warehouse.

Retrofit Concept

Retrofitting warehouses involves incorporating new technologies and systems in already existing facilities. This can include updating storage systems, implementing automated solutions, and improving infrastructure to meet energy efficiency and warehouse safety standards.

Advantages of retrofitting

Warehouse retrofitting has numerous benefits for companies:

- Cost Saving: Updating an existing warehouse instead of building a new one can considerably reduce initial investment and operating costs, as the new components are normally more efficient and require less maintenance.

- Improved Efficiency: Implementing advanced technologies, such as automated systems and inventory management software, can significantly improve storage and distribution processes, boosting productivity and reducing errors.

- Sustainability: Modernising existing facilities helps reduce energy consumption and the carbon footprint. Reusing existing structures and components is more environmentally friendly than building new facilities from scratch.

- Flexibility: Allows the warehouse to be adapted to new needs without the disruption that a new construction would entail. This is especially useful in dynamic business environments where demands can change rapidly.

Comparison with new constructions

It is essential to compare retrofitting with the construction of new facilities in order to make an informed decision. This analysis allows the evaluation of key aspects such as initial cost, implementation time, environmental impact and adaptability:

- Initial Costs: Retrofitting generally requires less investment compared to building a new warehouse. In addition, operating costs may also be lower thanks to the efficiency and quality of new components.

- Implementation Time: Retrofitting is normally quicker, since it does not involve starting from scratch, allowing operations to continue with minimal disruptions.

- Environmental Impact: Reusing and improving existing structures is more sustainable than building new ones. This reduces the consumption of resources and construction-related CO₂ emissions.

- Adaptability: Allows greater flexibility to adapt to future changes in operations. Retrofitted facilities can be altered more easily to incorporate new technologies or respond to changes in demand.

Planning a Retrofit Project

Meticulous planning is essential to ensure the success of a retrofit project. This process not only involves a series of well-defined steps, but also effective coordination between all those involved. The key steps to ensure the success of this project are set out below:

Initial Evaluation:

- Carry out a thorough analysis of the current state of the warehouse areas.

- Identify areas that require improvements, whether in terms of infrastructure, technology or operating processes.

Definition of Objectives:

- Set clear and specific goals for the project.

- Objectives can include improving energy efficiency, increasing storage capacity, optimising work flows, etc.

Selection of Technologies:

- Investigate and select the most appropriate technologies and systems to integrate in the warehouse.

- Consider options such as automated storage and retrieval systems (AS/RS), warehouse management software (WMS), and sustainable energy solutions.

Budget and Financing:

- Provide a detailed estimate of project costs, including acquisition technologies, labour and other operating costs.

- Ensure the necessary financing, whether through internal resources, loans or grants.

Implementation:

- Implement the project in well-defined phases to minimise disruption of daily warehouse operations.

- Coordinate with all the departments involved to ensure a smooth and efficient transition.

Evaluation and Adjustments:

- Monitor the post-implementation performance of the warehouse to ensure that objectives are being met.

- Make adjustments and continuous improvements where necessary to optimise results and adapt to new needs or challenges.

Retrofit Sustainability

Retrofitting a warehouse not only improves efficiency and operating capacity, but it also has a positive impact on sustainability. Some key aspects here are:

- Reduced Energy Consumption: Updating lighting systems to LED, improving thermal insulation and implementing more efficient air conditioning systems can significantly reduce energy consumption in the warehouse.

- Use of Sustainable Materials: Opting for racking and structures made of recyclable sustainable materials helps reduce the carbon footprint of the project.

- Waste Management: During retrofitting, it is important to implement waste management practices that include the recycling and reuse of materials whenever possible, minimising the environmental impact.

- Optimisation of Space: Installing high density racking and automated systems allows more efficient use of the space, reducing the need to physically expand the warehouse and, therefore, the ecological footprint of construction activities.

- Renewable Energies: Integrating renewable energy sources, such as solar panels, can make the warehouse more self-sufficient and reduce its dependence on non-renewable energy sources.

- Green Certifications: Seeking certifications can ensure that retrofitting is carried out according to the best sustainability and energy efficiency practices.

Implementing these practices not only contributes to environmental sustainability, but can also lead to significant long-term savings and improve the company’s corporate image.

AR Racking retrofits your warehouse

Retrofitting warehouses is an effective strategy to optimise existing facilities, offering significant advantages in terms of costs, performance and sustainability. With adequate planning, an obsolete warehouse can be transformed into a modern and efficient facility, ready to tackle future challenges.

If you are thinking about modernising your warehouse to improve efficiency, storage capacity and sustainability, at AR Racking we can offer you the advice and quality solutions that you need. Our team of experts is on hand to help you implement the best practices and technologies in your warehouse, ensuring that your investment has long-term success and benefits. Contact us to describe how we can transform your warehouse and take your operations to the next level.