Warehouses, particularly when built and equipped for the first time, are facilities designed for an efficient long-term useful life. However, we may end up finding that the warehouse becomes too small and that its storage capacity is insufficient. In such a situation we need to weigh up the options to increase the capacity of the warehouse.

Several factors must be considered when designing and configuring a warehouse: warehouse layout; type of product; product stock management model: Wilson model, Just In time…; initial investment capacity, etc.

Although the warehouse is configured optimally, it is not unusual to reach a point where it ends up becoming too small. In this blog, we will address the signs that alert us to this problem and some of the keys to increase storage capacity through different types of industrial racking, without having to address the need of acquiring a new warehouse.

Signs of a warehouse with reduced capacity

Lack of space in a warehouse or, rather, a reduction in the desired storage capacity can become apparent in several ways.

One of the most significant is a rise in incidents sent by the customer caused by loss of traceability of the product or because the product does not reach the customer in optimum conditions all the time. In any case, these are problems linked to incorrect use of the storage systems due to oversaturation.

Lack of storage capacity and loss of traceability or a traceability that requires constant review will inevitably affect delivery times, making the business less competitive.

Another sign that the warehouse has become too small are when operational difficulties arise for both personnel and mechanical equipment. Whatever the case, the industrial racking where the load or type of goods are stored, the location, loading and unloading must all facilitate smooth and agile operations.

If, apart from these signs, it is detected that there is a certain loss of safety in the warehouse with loading and unloading, moving the load from one warehouse area to another, etc., it is clear that the warehouse has become too small.

Increasing the capacity of the warehouse: 3 solutions and possibility

When a situation like this arises and if it is not possible to change the location of the premises that house the warehouse, the redesign and reinstallation of the storage systems will allow the warehouse to become an efficient, comfortable and risk-free space for personnel. How can this be done? There are 3 keys to increase the storage capacity:

Warehouse compaction: store more units in the same area

These are racking systems whose priority is to optimise the available space, prioritising high-density storage. In this case, storage capacity is gained in the same available space by reducing work aisles in favour of more storage positions.

Although access is not direct for all goods, compact storage systems (also called accumulation) do offer obvious advantages as well as increased storage capacity: more ordered logistics management, control over inventory, maximising return of every square metre of floor space...

There are various types of compact storage solutions:

Drive In / Drive Through:

This type of racking is designed to store pallets and is very common for homogeneous products with a high number of pallets of the same reference.

They can be the Drive in type, with a single access aisle, where the last load to enter is the first one to leave (LIFO method), and Drive through, with both an entry and an exit, where the first load to enter is the first one to leave (FIFO method).

Live Pallet Racking:

It increases the capacity of a warehouse with adjustable pallet racking. It is characterised by its high-density storage systems that incorporate an incline on which the pallets with the goods are moved inside the structure. In this case, there are also FIFO (first in first out) live pallet racking and LIFO push-back live storage racking systems.

The compaction of a warehouse is not only applicable to loads that are stored on pallets, the storage capacity for medium and small loads in cartons can also be increased. Carton flow rack systems work in the same way as live pallet racking.

Pallet shuttle racking:

Semi-automated solution for high-density storage uses motorised pallet shuttles which autonomously perform the movements inside the racking to move the load. Apart from reducing the work aisles, the pallet shuttle storage solution allows automatic control of the inventory through sensors that count the stored pallets.

VNA racking

In this case, instead of reducing the number of aisles, the space that they occupy is reduced to gain as many centimetres as possible on the racking. Very narrow aisle pallet racking combines the advantages of selective pallet racking and compact pallet racking systems to achieve a high-density storage system, but maintaining direct access to all the stored unit loads. The aisles can be reduced to a maximum width of 1.5 metres. They require specific mechanised resources.

Vertical growth: racking that allows you to increase capacity at height

The advantage of solutions that increase the storage density by reducing work areas such as aisles and accumulating more goods in the same space, is that they make the most of every square metre of floor space of the warehouse.

However, when talking about maximum use of space, it is important not to forget the height of the warehouse itself. There are storage solutions that allow growth at height, without losing the certain operational rigidity that compact systems provide.

Elevated walkways:

Designed for reduced area warehouses, but with the possibility of adding cubic metres for storage. They are mainly designed for loads that require manual operation. Aisle levels are created at different heights which are accessed by stairs. The actual structure is the racking where the goods are deposited.

Mezzanine floors:

Structure that increases the surface area of the premises, gaining useful space at height on one or two levels within a warehouse. These are independent structures, that come in a wide variety and types of floors. With the addition of a new floor for the warehouse, another area is offered quickly and economically in the warehouse.

| Compaction | Growth at height | Automation | |

| How | Elimination or narrowing of work aisles | Generation of more levels in the warehouse | Integration of automated machinery on high-bay compact racking |

| Storage solution | Drive in / DriveThrough, live pallet racking, push-back live storage racking, pallet shuttle racking, VNA racking | Elevated walkways, Mezzanine floors | Automated system for pallets, Miniload |

Automation of the warehouse: the all-in-one optimisation solution

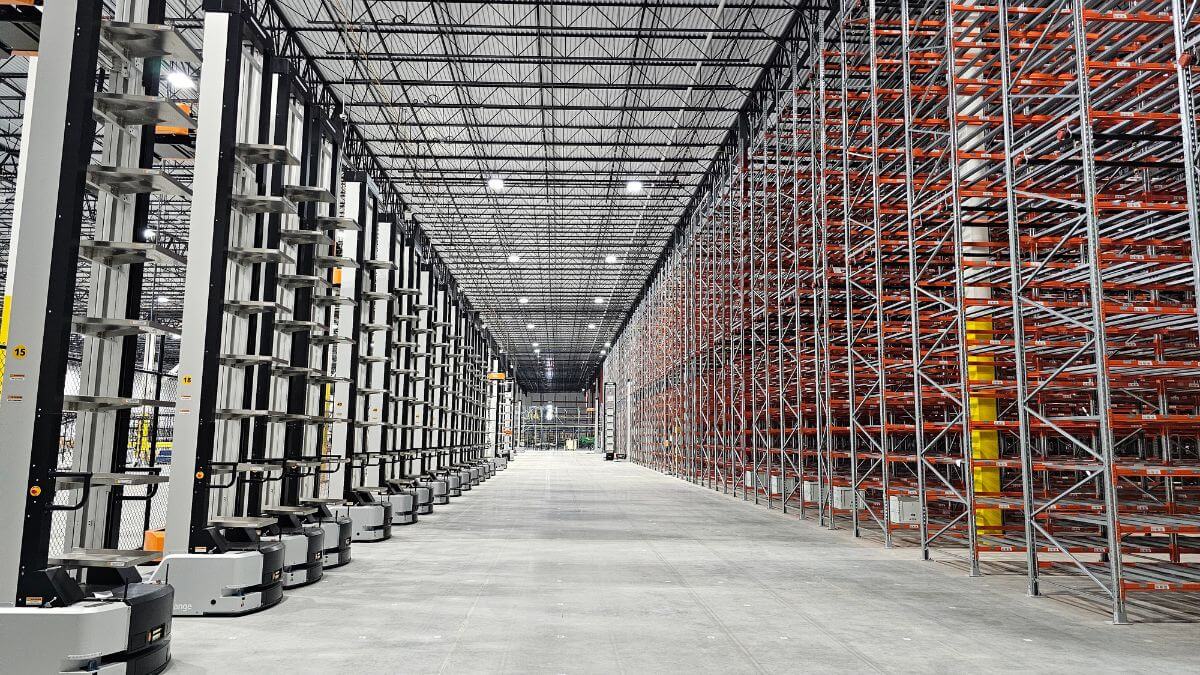

So far, we have talked about increasing the storage capacity, exploiting space horizontally or vertically. Nevertheless, there is a solution that combines both factors: automated warehouses.

Automated warehouses have become an increasingly requested solution. E-commerce, the pandemic, competition without borders, the demand for increasingly tight delivery times... are circumstances that have led to an increase in automated warehouses. These types of warehouses allow very high storage density (every millimetre of the warehouse is designed to store goods, reducing goods handling spaces to a minimum, performed by machines and automatic robots); and, generally, they are structures that reach greater heights than adjustable pallet racking systems, so the storage capacity of the warehouse is fully maximised.

Although they require a higher initial financial investment, automated warehouses, both for pallets and the cartons, offer numerous advantages for companies with an intense logistics activity:

- Agile flow of goods.

- Fast loading and unloading.

- Less risky logistics processes for personnel.

- Rigorous stock control.

- Notable decrease in operating errors.

- Maximum efficiency: more storage capacity, more handling capacity with reduced risk of incidents.

Warehouses can be automated both for pallet loads and for cartons.

Automated system for pallets:

When a warehouse becomes too small, its capacity can be expanded by reconfiguring its space and installing in its interior racking designed to store pallets and sustain the movement and weight of the automated elements such as stacker cranes or shuttles.

Automated system for miniload cartons:

If the cartons are the basic storage unit in the warehouse that need to increase their capacity, the miniload system is the answer. It is a system in which automated elements are integrated in the racking to handle goods that are stored in cartons or on trays, with an operator product system. It is especially indicated for those warehouses in which there is intensive picking, so it could be the ideal solution to increase the capacity of the warehouse that works with small and light loads.

Automated clad-rack warehouses are one of the most complete logistics solutions for when companies look to increase productivity with uninterrupted flows and continuous inventory control. However, if there is already a building in use, they are not the answer to expand the capacity of a warehouse by exploiting the building in which the company already operates, which is what we are discussing in this blog. Without going further, the main characteristic of clad-rack warehouses is that the racking forms part of the structure of the building, so we would be talking about a “reconstruction” of the warehouse and not maximising the capacity of an already existing installation.

In summary, the three keys to increase storage capacity through changes in racking systems are: compaction, exploitation at height and/or automation.

When a warehouse becomes too small, it loses its agility and errors and incidents start to arise; there is also an increase in unproductive relocation and error correction work. Operating times also lengthen excessively, so efficiency is directly weakened, having a direct impact on the quality of the customer service and, ultimately, the profitability of the business or company.

Contact our team for obligation-free advice if you need to increase the storage capacity of your logistics centre.