Drive in Racking

The Drive in Racking System (AR Drive In) is a high density storage solution that maximizes available space and height in the warehouse by reducing the forklift operating aisles.

It is made up of an easy-to-assemble and -reset modular structure, which makes it easy to maintain.

Compact racking can be either Drive in racking, with only one access aisle, where the last load in is the first one out, or Drive through racking, with an entrance and exit, where the first load in is the first one out.

It is the optimal and most common pallet storage system when you need to store homogeneous products with a large number of pallets of the same reference.

This compact system is appropriate where space utilisation is more important than selectivity of stored loads.

How does it work?

Drive in Racking system - AR Drive In

The AR Drive In compact racking system is the optimum solution for the storage of homogenous products with a high number of unit loads per reference.

It is a high-density pallet storage system designed to maximise the cubic space available by minimising the operating aisles needed for trucks.

Compact pallet racking systems enable excellent stock control in the warehouse, as each lane of the structure is exclusively for a product reference.

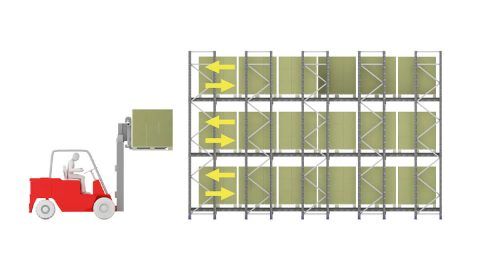

In this compact pallet racking system, parallel aisles are generated inside the structure, where the forklifts circulate to load or unload the unit loads.

The forklift handles the load at a height higher than the level at which it will be deposited and deposits it on the load support rails, which are located on both sides of each level.

There are two types of storage for the compact system, with the Drive in type being the most common:

Drive in pallet racking (LIFO - Last in, First out)

This is the most common compact racking system and only needs a single access aisle for the forklift. It uses the LIFO method, so the last load in is the first one out.

Drive in compact racking is indicated for warehouses with low material turnover.

Drive through pallet racking (FIFO – First in, First out)

This solution requires two accesses, one on each side of the racking. It uses the FIFO method, as the first load in is the first one out.

Because it allows access from both the front and rear sides, drive through compact racking is a suitable system for high turnover products.

Advantages

Advantages and features for Drive in Racking for pallets:

The main advantages of Drive in or Drive through compact pallet racking systems are their maximum compaction and optimisation of space and perfect stock control.

- Space optimization above 80%.

- Low maintenance and low assembly costs make this system one of the most cost-effective systems.

- Structure compatible with other storage systems.

- Provides maximum performance, and utilisation can be over 80% of the available space.

- Enables clearly arranged logistics management with full control of inventories as well as traffic and service flow.

- Designed to allow for quick reconfiguration of the structure for extension or change as needed.

- Ideal for storing low-rotation loads of the same type.

- Eliminates the service aisles found with a conventional pallet racking system.

- Maximised storage floor and height.

- Easily assembled modular structure.

- Trucks enter the system for loading.

- Includes various accessories to increase safety.

- Maximisation of space.

- Products of the same type.

- Low stock rotation.

Main applications of Drive in compact pallet racking systems:

This is the most common and widely used static compact system. Its configuration for both FIFO and LIFO management makes it a versatile type of racking solution.

It is mainly applied in the following situations:

- Warehouses with reduced available space or with a high cost per square metre of the floor area, making it necessary to fully optimise this space.

- Need to store homogeneous products with a large number of pallets of the same reference, and with a low turnover.

- Warehouses for non-perishable merchandise and whose time in stock is not relevant, as with the Drive in racking system (LIFO Management).

- Warehouses for perishable products as with the Drive through racking system (FIFO Management).

- Warehouses where direct access to the unit loads is not required.

- Warehouses with cold stores or freezing chambers, due to the need for compaction and space optimisation for a correct temperature distribution and cost savings.

Components and accessories

Drive In Racking system structure:

The Drive in storage system is made up of sets of frames and vertical uprights joined together to form inner lanes.

Drive-in pallet racking is the appropriate solution for homogeneous loads without a great need for rotation and for cold stores, due to its great compactness.

Each lane is equipped with support rails on both sides, laid out at different levels, on which pallets are placed. For loading and unloading operations, the forklift truck enters the lanes with the unit load lifted above the rail where it will be placed.

This compact storage system allows as many SKUs as loading lanes. Depth and height are dependent on the number of pallets to be stored.

Main components and accessories of Drive in systems are:

Upper longitudinal beam

The upper longitudinal beam joins the frames in the upper area crosswise, to secure the structure by creating gantries. The beams must be placed in all the compact racking aisles.

Horizontal brace

The horizontal brace is a metal component that reinforces the compact structure and is located at the top.

Frame

The frame is one of the basic elements of Drive in compact racking. These frames consist of 2 uprights, their corresponding diagonals, baseplates and fixing elements.

Forklift guide rail

This is a steel rail at floor level that runs along the whole aisle. Its objective is to guide the forklift when it enters the structure and protect it against possible impacts. It helps to separate the forklift from the Drive in compact racking.

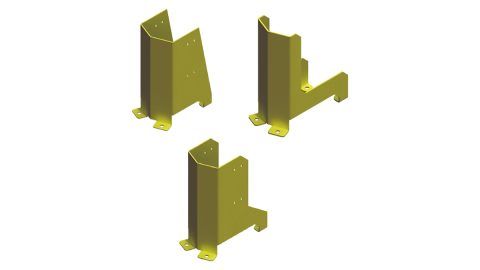

Frame and upright protection

The frame and upright protectors protect the installation from possible damage due to impacts by the forklift.

Welded baseplate

The welded baseplate is an especially designed component for frames with the highest load and height.

Upright

The upright is the main element of the frame and is galvanised. The customer has available to them a wide variety of upright sections and lengths to adapt to their warehouse needs.

Pallet guidance

It is situated at the front of the pallet beam or pallet support rail and helps operators when depositing the unit loads. It also protects the structure against potential impacts.

Pallet beam or support rail

These are the horizontal profiles on which the pallets on each level of the Drive in racking system are supported. They are metal and are perpendicularly secured to the upright by means of the brackets.

Bracket

Brackets are the metal components that support the support rails or pallet beams on each level, and therefore indirectly support the pallets. This component is secured to the upright.

Pallet backstop

Pallet backstops are preventive safety backstops and their main function is to prevent the pallet from falling at the back of the aisle due to any inappropriate manoeuvre.

Quality and security

Drive in and Drive through pallet racking solutions comply with the strictest European safety standards, and also come with AR Racking’s quality and innovation guarantee.

5-year quality guarantee

The reliability of our compact pallet racking solutions means we are able to offer 5-year quality guarantees against all types of manufacturing or hidden defects in the components of the main structure of our racking solutions.

Pioneering component traceability system

Since 2016, our compact pallet racking uprights have included a component traceability system.

With this system, the various above-mentioned elements have an identifying mark, which means being able to trace and document each upright without needing the package label, and therefore knowing which component it is, its design and what raw material has been used in its manufacture.

100% automated production

Our industrial racking component production process is fully automated: it incorporates state-of-the-art profiling machines with a continuous cutting process and laser measurement control, welding centres and automated painting and packaging processes, which guarantee the highest quality parameters.

Designs in R&D&I Centre

Both our Drive in and Drive through compact storage systems are designed in our exclusive R&D&I technology centre and supported by the advanced engineering project development area, allowing us to respond suitably to the most demanding logistics requirements.

Tests at Research and Testing Laboratory

With the creation of our Research and Testing Laboratory in collaboration with the University of Mondragón, our product area continuously tests and analyses products to improve our drive in and drive through compact pallet racking systems; it simulates, calculates and researches (with specialist software) the efficacy of the geometries, and makes full structural calculations on the behaviour of the systems already installed in different situations.

International certificates for the Drive in Racking system:

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007

References

References

In our more than 26,000 storage projects carried out in over 60 countries, we are fortunate to have implemented Drive in compact racking solutions to optimise the warehouses of major international companies from various sectors: food and beverage, automotive, distribution, electronics, pharmacy and cosmetics, industrial and transport and logistics.

Some featured Drive in Racking projects: