Racking Systems for Pharmacy and Cosmetics companies

The pharmaceutical industry is one of the most important industrial sectors. It has complex and demanding logistics and storage challenges due to the peculiarity of the products, since they need specific temperatures, exact delivery times, emergency situation responses, etc.

Companies require state-of-the-art storage capabilities to adapt to the requirements and needs of each product. Facilities must obtain optimal performance by increasing collection speed and maximising density.

At AR Racking we have these very characteristic storage needs due to our broad experience in adapting to special storage solutions.

Storage systems for the pharmacy and cosmetics industry

Stock rotation: priority

The pharmacy and cosmetics sector is characterised by high product rotation due to the expiry or obsolescence of its goods, so systems with direct access to the unit loads or managed with the FIFO stock method are usually installed.

Direct access to the unit loads

It is a sector with a very high order preparation rate due to the tight delivery deadline requirement by customers, so the system to be installed must help facilitate this process with direct access to all the unit loads.

Manual picking systems

Warehouse operations in the final phases of the supply chain of the pharmacy and cosmetic sector usually involve fast order preparation, for which picking storage systems are installed that allow easy and quick location of goods.

Controlled temperature storage

Algunos productos de las empresas farmacéuticas y cosméticas requieren ser almacenados en condiciones de frío, y para ello se deben instalar estanterías industriales adecuadas para estas condiciones.

Some products of pharmaceutical and cosmetics companies need to be stored in cold conditions, for which appropriate industrial racking must be installed for these conditions.

Characteristics of the pharmacy and cosmetics industry

Pharmaceutical storage requires very special characteristics and conditions that differentiate it from any other type of logistics. Storing and distributing medicines, active ingredients and other biological products require special storage conditions, which is why they are subject to strict control to guarantee risk-free consumption.

Inventory control

Inventory control is essential for the rapid identification of batches of products and drugs in case they are affected by any anomaly or irregularity. This is coupled with the demanding quality controls, very necessary for the discarding of drugs that do not work.

Special preservation

Special storage and distribution conditions are the most important characteristics, as the products need special preservation. Pharmaceutical warehouses must therefore be equipped with special areas, together with safety factors.

Recommended Industrial Racking:

Some common storage systems for the pharmacy and cosmetics industry are

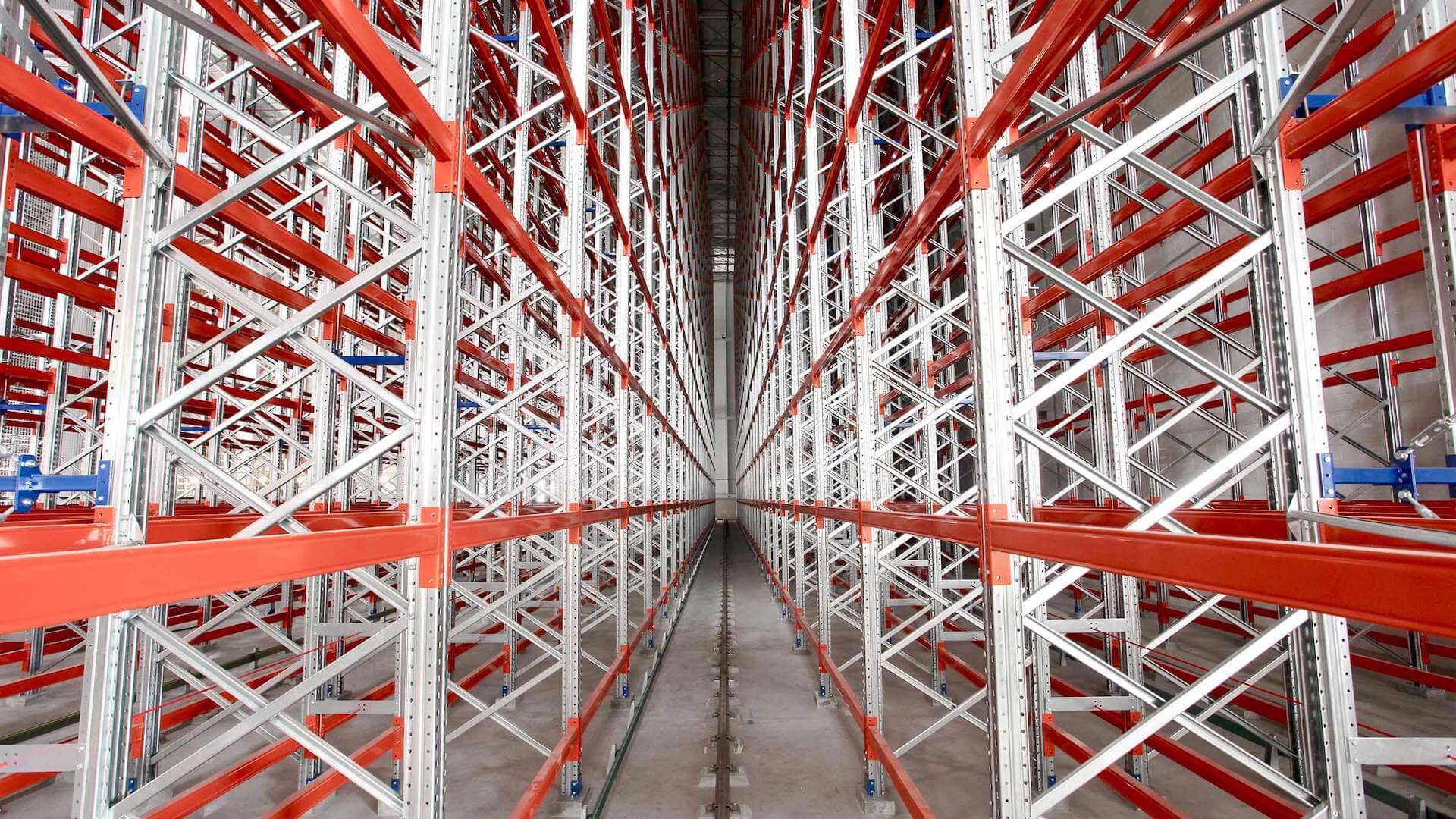

AS/RS Systems for pallets

Storage system that offers high density storage thanks to the reduced number of work aisles and its storage capacity at height.

Miniload

The miniload system allows the daily inventorying of stored medium and light products and minimises load handling errors.

Longspan Shelving

This system allows the manual storage of small and medium size materials, is highly versatile and facilitates direct and immediate access to the stored references.

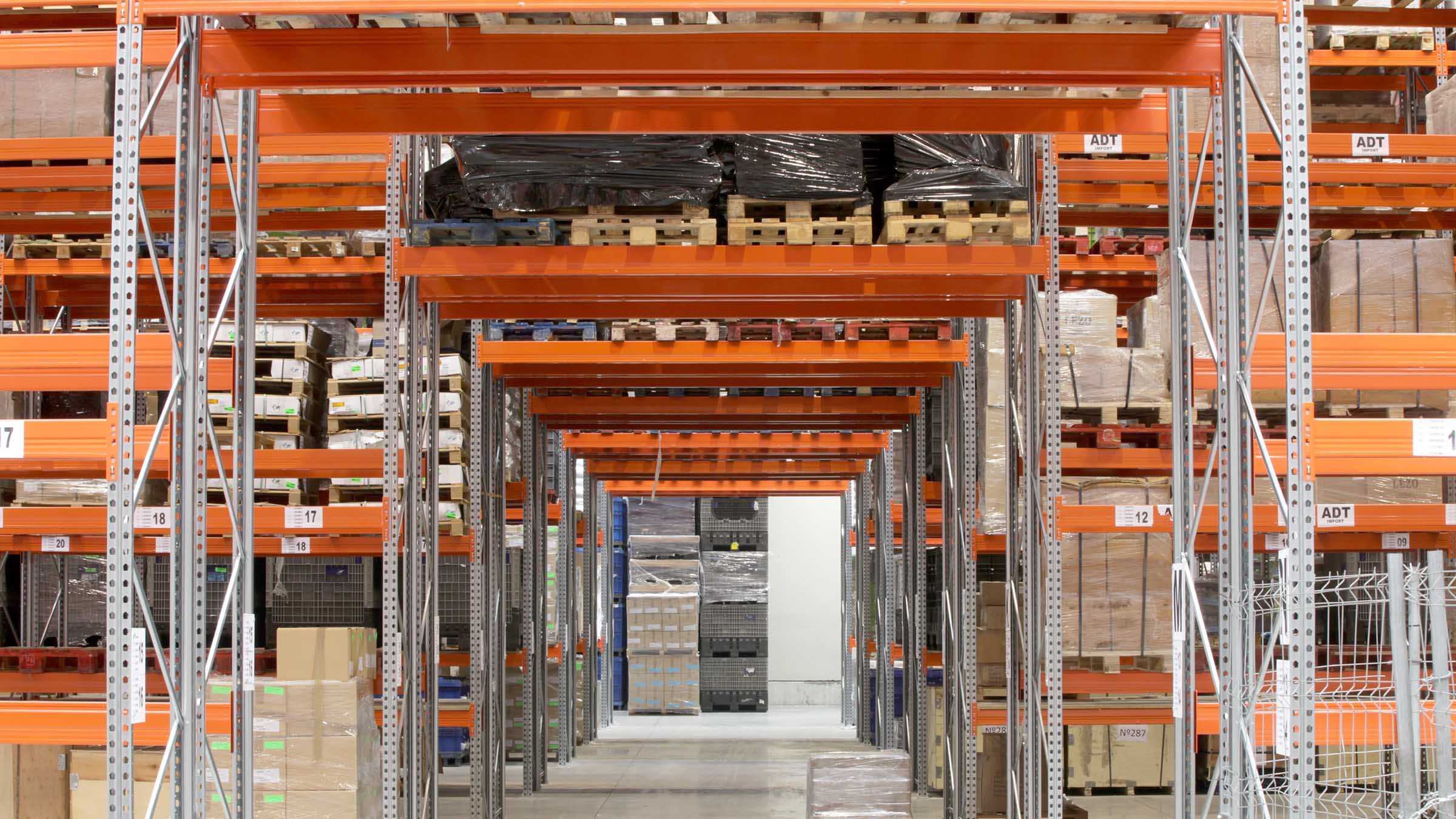

Adjustable Pallet Racking

Very common and simple storage system which allows direct and immediate access to the goods, as well as the rapid location of each pallet to save goods handling time.

Narrow Aisle Racking

Very similar to adjustable pallet racking systems, but recommended for pharmaceutical and cosmetics companies, as the warehouse capacity can be increased without expanding the space thanks to the narrowing of the work aisles.