The main functions of logistics are the planning, execution and control of products to be delivered to a customer to ensure their arrival on time in the right quantity and quality. That is, all the phases involved from the manufacturing of the product to final delivery. It is one of the most important parts of a company.

The objective is to link all phases of the supply chain, for which optimal stock control is necessary.

The logistics department in a company has two key factors, namely speed of delivery and strengthening customer relations. The customer always expects to receive the product as quickly as possible and the company expects its loyalty.

The main functions of logistics

These are the main functions that logistics must fulfil in a business organisation:

Order processing

This is the process of receiving, processing and fulfilling orders placed by customers. It is a very important part of the operation of a company so that the end customer is satisfied.

This process begins when a customer places an order and ends when it is delivered. For its correct process it is divided into different stages. For this, it will be key to choose a storage system that speeds up and facilitates the preparation of orders, that enables the simple loading and unloading of unit loads and that allows the different goods to be correctly located.

Material handling

One of the functions of logistics is to manage all the movement of goods within a company, from the beginning to the end of the supply chain.

The optimal process would be for all product movement to be carried out safely, at a low cost and without damaging the product.

Inventory

It is a process for the company to manage the stored stocks they have of the products. It is a way of controlling the quantities needed to be able to replenish inventory.

This process provides information on which products are in greater or lesser demand.

In these cases, the AR Shuttle system enables automatic inventory control using sensors that count stored pallets. This system, developed by AR Racking, significantly reduces margins for error thanks to the remote control and barcodes that achieve greater stock control.

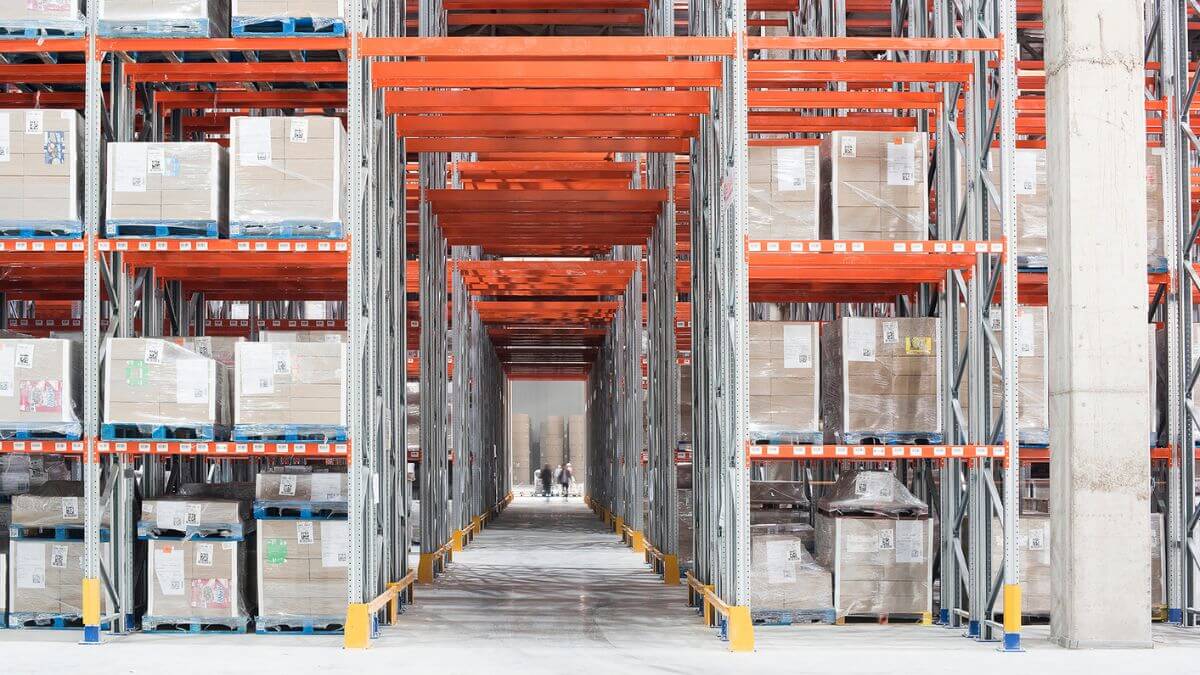

Warehouse management

It is one of the most important functions within a logistics facility. Correct management helps eliminate cost overruns and ensure an appropriate process during demand peaks.

For these reasons it is very important that the structures in which goods are stored are suitable for each product. For example, if the product to be stored does not lose value over time, does not expire or is not perishable, the LIFO stock management method would be used. A method that prioritises the issue of the last batches of products to enter the warehouse.

Packaging and labelling

It is essential that any product is well packaged to avoid problems during transportation. It is therefore very important to have appropriate packaging for each type of goods. The label must provide essential information about the product, such as the date or whether the goods are fragile or dangerous.

Transport and distribution

They are the processes that ensure that the product reaches the customer efficiently and in the shortest possible time.

The digitisation of processes is essential to reduce costs creating detailed planning.

Traceability

This allows us to know all the stages of the logistics process, and where the product is at all times.

There are two types of traceability: internal and external.

Internal traceability covers the journey of products through the company's production chain until shipment.

External traceability, on the other hand, is the identification and registration system that is launched outside the company's limits. The moment the product leaves the company until it reaches the end customer.

Information and control

It is the way for companies to have clear visibility of actions carried out in the supply chain.

Obtaining information in real time is very useful to evaluate the effectiveness of deliveries. Therefore, the acquisition of new technologies is essential to always facilitate the control of all processes.

Reverse logistics

This is the planning and control process for the return of products from consumption or end user points to the manufacturer or distributor for their recovery, repair, recycling or disposal.

This has several advantages such as caring for and reducing the impact on the environment. It also reduces costs, reusing materials in order to save on the purchase of raw materials. Resource consumption is reduced too, minimising the purchasing and supply costs of materials. There is also a better customer and supplier relationship, an advantage for both.

After-sales

These are all the actions carried out once the sale is completed. This function is essential to know customer satisfaction.

What are the benefits of logistics?

Optimising a company's logistics offers many advantages and improves results. These are some of the benefits:

- Expedition and faster services

Delivering products in the shortest possible time is essential and for this it is important to have good logistics and organisation.

- Efficiency

The use of ERP with a logistics module enables effective control of the supply chain, reducing expenses and errors.

- Customer satisfaction

Good management allows us to offer a good, quality service to ensure customer satisfaction.

- Avoids possible errors

With new technological advances and a large part of the management automated, many errors are avoided and the quality of service is improved.

- Analysis

With digital tools, a large amount of data is managed. As a result, you can obtain reports and analyses with very useful information, important for assessing the effectiveness of processes and implementing strategies.

Objectives to achieve with correct logistics planning

The success of a commercial action is thanks to all the logistics behind it and understanding the objectives is essential to ensure the efficiency and competitiveness that all companies should consider.

- Increase competitiveness

Competitiveness is increased by making fast deliveries and offering accurate and quality information to the parties involved in the logistics process.

- Anticipate needs

Adequately forecasting consumer needs is important.

- Calculate the best stock

A correct level of stock is needed to avoid overstock or obsolescence of items.

- Strengthen customer and supplier relationship

It is important to gain the customer’s trust. For this the entire logistics process needs to be perfect, guaranteeing on-time deliveries with the agreed results and quickly resolving any possible incident.

- Take care of consumer service

The entire purchasing experience must be taken care of, from first contact to product delivery.

- Optimise operating costs

It is important to fulfil delivery times and prepare orders properly, as any error in the product shipment means an added expense by having to return it and send it again.

- Plan the best routes

It is important to choose the best distribution route possible to avoid delays and other setbacks, and to ensure the delivery of the goods in optimal conditions within the agreed deadline.

- Care for the environment

Sustainable logistics includes a set of practices to limit the environmental impact in transport or storage and also optimise times and costs.

In conclusion, logistics is a very important phase for a company and it is vital to carry out all its phases correctly.

At AR Racking, as experts in storage systems, we are open to supporting the optimisation of a company’s warehouse by providing an extensive catalogue of storage solutions that adapts to any space or need.