Materials storage is an essential process that allows companies to have at their disposal the products and raw materials necessary to meet the demands of production lines. Proper organisation of raw materials not only improves logistics efficiency, but also streamlines manufacturing processes.

What is a raw material warehouse?

A raw material warehouse is a facility dedicated to the preservation and storage of the basic materials necessary for the manufacture of products. In this type of warehouse, unprocessed goods are stored, that is, goods that have not gone through any production process, hence they are the initial resources used in the manufacturing of products before undergoing transformation processes. In an industrial context, stored items are usually materials such as fabrics, metals, wood, plastics, chemicals and other components necessary for production.

Organisation and management of raw materials

Raw material warehouses typically have inventory systems, quality control and safety measures in place to ensure the safety of stored materials. Organisation and efficiency in the management of a raw material warehouse is crucial to optimise and ensure a constant supply of the resources necessary for production, avoiding errors and problems in inventory management, for which it will be necessary to correctly define which storage system to use. Likewise, these warehouses are normally located near the distribution centre or the site where these materials will be transformed in order to streamline the movement of goods. In supply logistics, coordination between warehouses and production centres is essential for efficient operation.

Traceability of materials

Product traceability is a key feature in any logistics facility, and especially important in a raw material warehouse. The logistics manager must know the exact location of the products and control the handling processes of all goods to guarantee quality standards in the production process.

When planning the design of the warehouse and storage systems, variables such as the type of goods, production needs or product demand must be considered. The layout of the warehouse is crucial in supplying production, because the correct distribution of space facilitates the storage and movement of goods to the production lines.

Characteristics of a raw material warehouse

To be efficient, a raw material warehouse must combine storage capacity, organisation, safety and control to ensure a smooth and reliable supply flow that supports industrial production.

These are some of the main characteristics that a raw material warehouse must fulfil:

Strategic location

The warehouse must be strategically located to facilitate access to raw materials and reduce transportation costs. It must also be easily accessible to suppliers and have efficient connections with the production plant to reduce costs and time.

Adequate storage capacity

The warehouse must have sufficient capacity to store the raw materials necessary for production and supply. Both physical space and load capacity must be considered. Thus, the design and layout of the warehouse must maximise efficiency in the reception, storage and distribution of raw materials. This may include the implementation of technologies such as warehouse management systems.

Temperature and humidity control

Depending on the nature of the raw materials, it may be necessary to maintain specific temperature and humidity conditions to preserve their quality as some products, such as fresh or perishable products, may be sensitive to environmental variations. Therefore, it is important to have an adequate cooling system and control the temperature of the materials at all times.

Efficient organisation

It is essential to have an efficient organisation system to facilitate the location and recovery of raw materials, so traceability is essential to ensure the quality of the materials and guarantee the safety of the final product. This may include a detailed record of suppliers, labelling systems, delivery and expiry dates and an inventory management system. It is also important to maintain rigorous inventory control and properly manage the inflow and outflow of materials to avoid waste.

Proper handling of materials

Raw materials must be handled meticulously and correctly to avoid damage to them. Therefore, depending on the nature of the raw materials, adequate equipment and procedures must be provided for the safe handling of the materials. This may include the presence of cranes, forklifts or other specialised equipment.

Regulatory compliance

You must comply with local and national regulations on the storage and handling of raw materials. This includes safety and environmental regulations and any other industry-specific requirements. Maintenance tasks must also be performed to ensure that all facilities and equipment are in good condition.

Flexibility

The warehouse must be flexible enough to adapt to changes in demand and the variety of raw materials used in production.

Main objectives to achieve

The objectives of a raw material warehouse may vary depending on the type of industry and business strategy, but generally include the following aspects:

Maintain and protect the quality and safety standards of materials

The warehouse must implement quality control measures that ensure the good condition and quality of raw materials, complying with all regulations and standards, and the safety of the movements of goods to avoid defects in the final products and maintain customer satisfaction.

Guarantee and control stock management

The warehouse receives goods from suppliers and sends them when there is a production order that demands that particular raw material. It is therefore necessary to ensure a constant and timely supply of the main stored materials for production. This means ensuring prior organisation and management to adapt to the needs of the item to be produced, as well as adequate inventory levels. The logistics manager must also monitor metrics such as safety stock or the reorder point.

Reduce losses and storage costs

Implementing practices and processes that reduce losses and waste of raw materials, such as including proper management of expiry dates, inventory turnover and early identification of obsolete products, is vitally important to reduce raw material losses and waste.

Look for ways to minimise the costs associated with the storage of raw materials, such as those related to space, inventory management and logistics management. This may include implementing just-in-time inventory management practices to avoid overstocking.

Improve efficiency

Continuously look for ways to improve efficiency in warehouse operational processes, such as in the receipt, storage, picking and dispatch of raw materials. This may involve the use of technologies such as RFID or the automation of certain processes.

How should raw materials be stored?

Proper storage of raw materials is essential to preserve their quality, avoid waste and facilitate efficient production flow. Some common practices for correct storage of basic materials are outlined below:

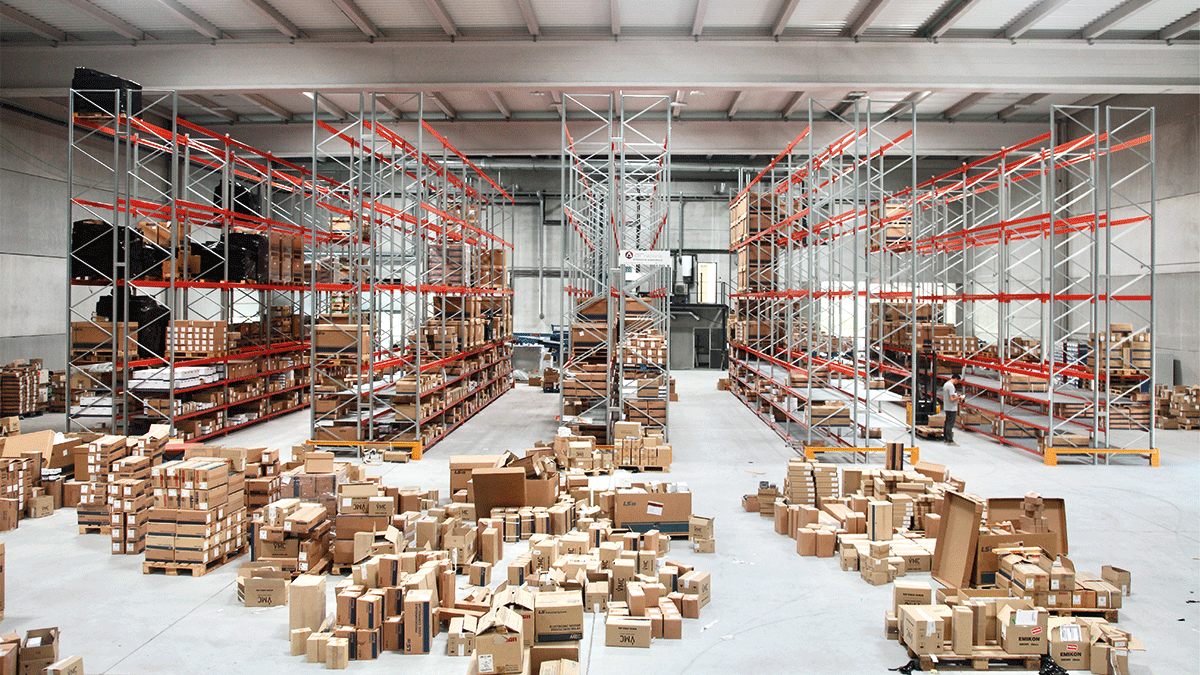

Warehouse evaluation

Before making any changes, it is important to evaluate the current state of the warehouse. This includes measuring the available space, reviewing the physical layout, identifying problem areas and evaluating the efficiency of current processes.

Space planning

Planning the layout and space of the warehouse efficiently and assigning a suitable storage location is crucial. Firstly, it is important to be clear about what raw materials are going to be stored and how they are going to be used in production. It is also important to consider the type of storage for each raw material since some may require special storage needs. Finally, it is important to consider the frequency of use of each raw material to organise the storage location.

Labelling and coding

Implementing a clear labelling and identification system is vital to identify each type of raw material and its location. In addition, it is necessary to categorise them according to their type, usefulness and expiry date to ensure correct storage of raw materials.

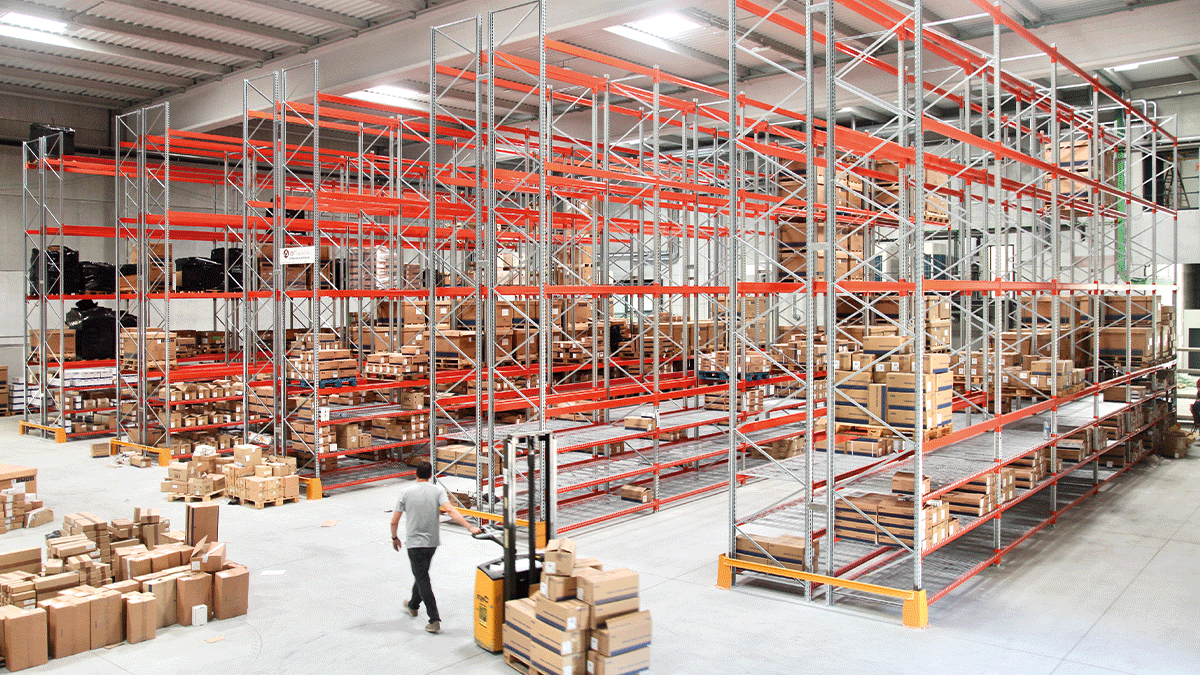

The use of specialised racking and storage structures can be beneficial to maximise the use of available space and ensure convenient and efficient access to raw materials.

Application of FIFO inventory management

Organise raw materials according to the FIFO (First In, First Out) method, where the first good or unit load to enter the warehouse is the first one out. This helps minimise the risk of obsolescence and waste. This also helps avoid the accumulation of raw materials that are not frequently used.

Advantages of a raw material warehouse

Designing, planning and implementing a specific warehouse for raw materials offers a series of significant advantages that directly impact the operational efficiency and profitability of a company. Some of the most notable advantages include:

Greater production efficiency

A well-organised warehouse contributes to greater productivity across the supply chain. By providing quick and efficient access to raw materials, production levels can be increased and delivery deadlines met more consistently.

Optimisation of space

By organising a raw material warehouse efficiently, you maximise the use of available space. This allows more raw materials to be stored in the same space, reducing the need for expansion or rental of additional facilities.

Cost reduction

Adequate organisation of a raw material warehouse organisation helps minimise operating costs by optimising the use of resources such as space, labour and equipment. By reducing the handling and search times for materials, costs associated with wasted time and additional labour can be reduced.

Likewise, correct organisation reduces the probability of errors in the entry, storage and distribution of raw materials. Furthermore, by following principles such as FIFO (First In, First Out), the risk of expiry is minimised and losses associated with product expiry are reduced.

Greater safety

An organised and clean warehouse helps ensure a safer environment for staff. Clear identification of raw materials, proper storage and the removal of obstacles reduce the risk of accidents in the workplace.

Improved work process

An organised warehouse facilitates work flow by reducing search and handling times for materials. Products can be found quickly and with direct access to them, which streamlines production processes and reduces downtime.

At AR Racking, as experts in the design and manufacture of industrial warehouse racking systems, we are aware of the importance of correctly storing raw materials.

If you need advice or would like to request a quote on industrial racking for your warehouse, our experts will advise you on the best storage solution.