Pallet racking systems adapted to cold or freezing environmental conditions are currently one of the most demanded storage solutions, mainly by food and biochemical companies.

Storage systems for cold stores have specific characteristics that differentiate them from those of other projects. Depending on the needs of each project, one type of metal racking or another may be more appropriate, or even different racking combinations may be used to provide the optimum result for the customer.

The main peculiarity of cold and freezing storage, in addition to the temperature itself, is the need for greater compaction of the pallet racking system to ensure greater energy efficiency of the cooling and thus save costs on each cubic metre of cold storage.

Of vital importance therefore in these cases is: the quality of the pallet racking system for correct resistance to extreme environmental conditions, and the appropriate design of the storage solution by an expert technical team to ensure optimum and uniform cooling of all warehouse unit loads.

In the case of AR Racking, as an expert in storage solutions for cold stores and freezing chambers, it develops and designs at its technology centre the structures of these pallet racking systems to adapt them optimally to these environmental conditions.

In addition, AR Racking’s galvanised product is more corrosion resistant than other types of metal structures which makes it the ideal element for cold storage.

ANOTHER ELEMENT IN THE COLD CHAIN

It should be remembered that the pallet racking system, the warehouse and its cold store are just another element in the complex process of the cold chain.

The cold chain incorporates the set of processes and elements that enable the maintenance of a product with certain temperature needs from when it is produced or collected, through its transport and storage, until it reaches the end user at the point of sale.

The entire chain needs to work perfectly so that the product, usually perishable, arrives in perfect condition at its final destination. The two elements that most affect the chain are ambient temperature and the exposure time of the product to it.

As soon as storage comes into play in this chain, special attention will need to be paid to the transition between the transport phase and the storage phase, i.e., in the loading and unloading time of the goods. In this case, excessive exposure time of the product at unsuitable temperature conditions may result in a thermal difference that breaks the stability of the cold chain.

MAIN STORAGE NEEDS IN COLD STORES

Focusing specifically on storage systems, the following points must be considered when choosing the most suitable type of pallet racking system for a cold storage project:

- Optimisation of the space used for good cooling

- Pallet racking material resistant to adverse conditions

- Maximisation of the storage capacity of the store

- Savings in warehouse supply costs

- Reduction in loading and unloading times

- Temperature uniformity

- Facilitating access to unit loads

PALLET RACKING SYSTEMS FOR COLD STORAGE

The following are the pallet racking systems which, for their composition or characteristics, can be adapted to storage situations in cold stores or freezing chambers, some of them being more efficient than others in terms of compaction and time reduction.

Adjustable pallet racking systems for cold storage

The adjustable pallet racking storage solution for palletised loading is a storage system designed to store pallets mechanically using forklifts.

The pallets are accessed via aisles whose dimensions vary according to the storage needs and available space.

In the case of cold stores, and although it is not a compact system, the adjustable pallet racking system is very versatile and can be adapted in height, width and length, creating modular and adapted solutions to optimise space and save on storage costs. It can be useful for use in conjunction with other compact storage systems.

The galvanised uprights make this an ideal pallet racking system to withstand the adverse environmental conditions inside a cold store or freezing chamber.

Advantages of the adjustable pallet racking system for cold or freezing storage:

- Direct and immediate access

- Reduced time and effort

- Adaptability and versatility

- Combinable with other pallet racking systems for cold stores.

Mobile racking in cold stores

The mobile racking system for pallets adapted to cold rooms is designed to compact the racks and significantly increase the storage capacity.

It is therefore a perfect high-density system for cold storage, as the individual access aisles characteristic of an adjustable pallet racking system are not required, maintaining a single access aisle to the stored material.

The work aisle is opened automatically by electric motors and displacement devices situated at the base of the racking. The operator is in charge of giving the order to open the aisle with a remote control.

These characteristics make it one of the optimal storage systems for cold and freezing storage, by reducing the total volume to cool.

Advantages for cold storage:

- More than 80% increase in the storage capacity of the store.

- Maximum use of space.

- Energy saving by reducing the space to be cooled and lighting control.

- Direct access to all loads

- Allows circulation with the “night setting” mode

- Reduced operating costs thanks to the excellent use of space.

Drive In Compact Pallet Racking Systems

Drive In Compact Pallet Racking systems are a high-density pallet storage racking system designed to make the most of the available space and height while minimising the work aisles of the truck.

This Drive In racking system is frequently used in cold stores and freezing chambers for its ability to optimise space efficiently.

You only need one access aisle, from which loading and unloading is performed, resulting in greater racking compaction.

Advantages of Drive-In Pallet Racking:

- Profitability of the total space available.

- Energy saving by reducing the space to be cooled.

- Ideal for storing uniform loads

- Elimination of service aisles

- LIFO (last in, first out) logistics management

Racking with AR Shuttle for cold store

The pallet racking with AR Shuttle system is a semi-automated compact pallet storage solution that uses motorised pallet shuttles that perform the movements inside the racking.

This system maximises the available space and height, minimising the work aisles of the truck, which makes it ideal for operation in a cold store or freezing chamber.

The AR Shuttle system enables automatic inventory control, and stored pallets can be loaded and unloaded in FIFO or LIFO mode in freezing chambers with temperatures as low -30ºC.

Advantages of pallet racking with the AR Shuttle system:

- Maximises storage capacity.

- Reduced pallet loading and unloading times, when moving the AR Shuttle.

- Energy saving by reducing the space to be cooled.

- Possibility of both FIFO and LIFO logistics management.

- Remote control of up to 4 pallet shuttles with the same control.

FIFO Live Pallet Racking and LIFO Push Back Racking

The live storage system for pallets is a compact system which, by means of roller conveyors and a slight incline, allows the sliding of palletised products on the rollers.

It is a perfect high-density storage system for storing homogeneous pallets, and ideal for cold rooms due to optimising the available space.

Live pallet racking makes it possible to work with the FIFO system and push back racking with the LIFO system, using the force of gravity and pushing force respectively.

Advantages of live storage systems for cold or freezing storage:

- Optimum use of space

- Rapid and simple extraction.

- Reduction in manoeuvring and loading and unloading times.

- Energy saving in cold stores.

- Improved stock control

- Compatible with other storage systems

- Reduced operational costs

AUTOMATED SOLUTIONS FOR COLD STORAGE

Along with the solutions presented, there are also storage systems which support automation equipment and that adapt to the needs of a cold store or freezing chamber.

The principal automated storage systems can be divided into: clad-rack warehouses, automated warehouses and miniload systems.

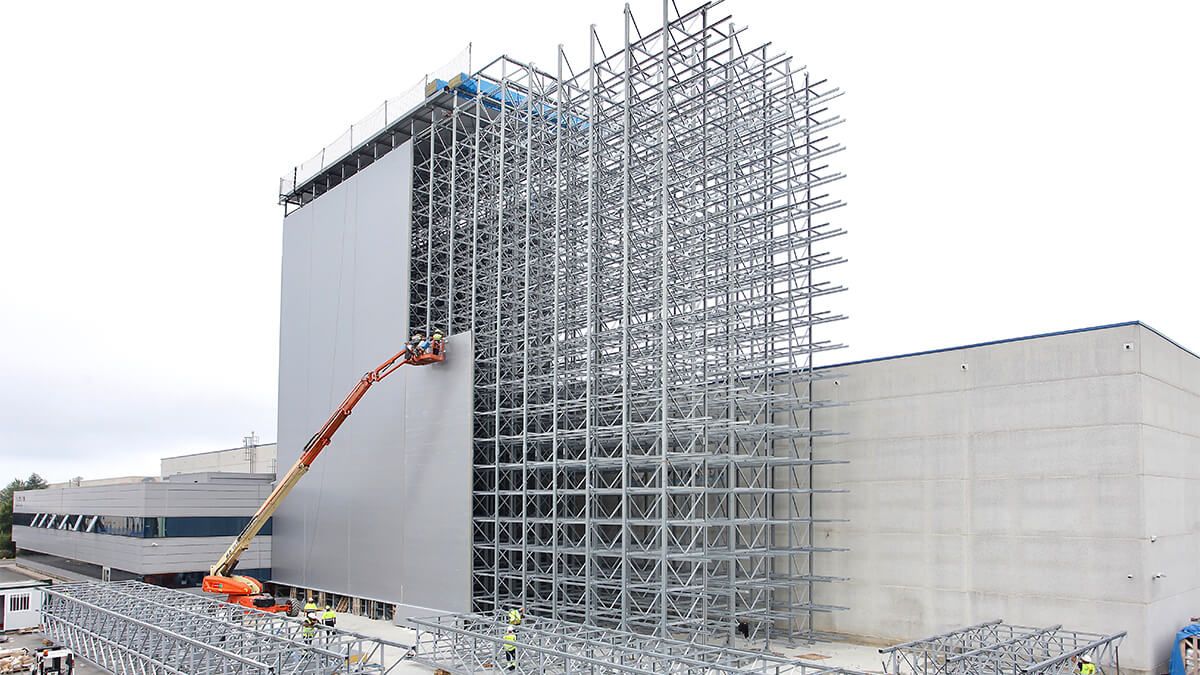

Clad-rack warehouse

In clad-rack warehouses the racking forms part of the building structure.

The racking supports the load of the stored goods and the external enclosures, and is the most suitable solution for storage at great height.

The system also perfectly adapts to warehouses that require cold work or in freezing chambers for total maximisation of the space.

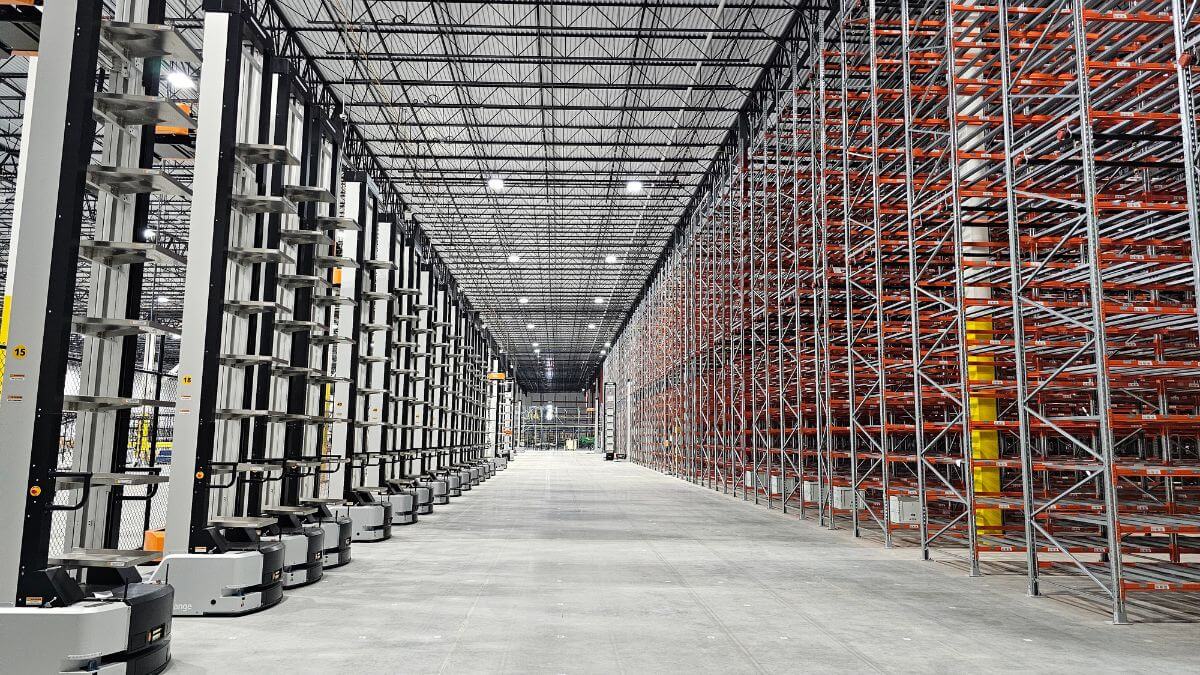

Automated warehouses (AS/RS Systems)

Automated systems with stacker crane for pallets are automated storage systems that use robotic equipment for the handling of loads.

It is a fast and reliable high-density system making it suitable for storage in cold or freezing conditions.

The system consists of small AS/RS machines (pallet shuttles) which simultaneously and autonomously load the controlled goods through a warehouse management system.

Miniload

The miniload system uses robotic equipment for the direct handling of plastic boxes or trays.

It is also a high-density system and therefore ideal for cold storage, due to the reduced number of work aisles and optimum use of surface area and height.

It is the optimal solution for implementing together with logistics solutions for semi-automated or fully automated order preparation.