Nowadays, the speed at which retailers must adapt to the online sales of their products is forcing them to restructure the whole supply chain and especially the warehouse. This has given rise to the concept of Micro-Fulfillment, which is a storage model that has become particularly relevant in recent years, especially in the e-commerce, food and beverage and pharmaceutical sectors, in order to bring the product closer to the end customer.

Micro-Fulfillment has become one of the favourite methods in the supply chain world. The possibility of sending products to consumers quickly and effectively is an undeniable advantage for retailers. Consumers currently have very high expectations of what their online shopping experience should be like. They therefore demand that companies have an exhaustible supply of stock, real-time updating of product status and that delivery is as quick as possible ensuring a positive experience during the whole process.

What is Micro-Fulfillment and what does it consist of?

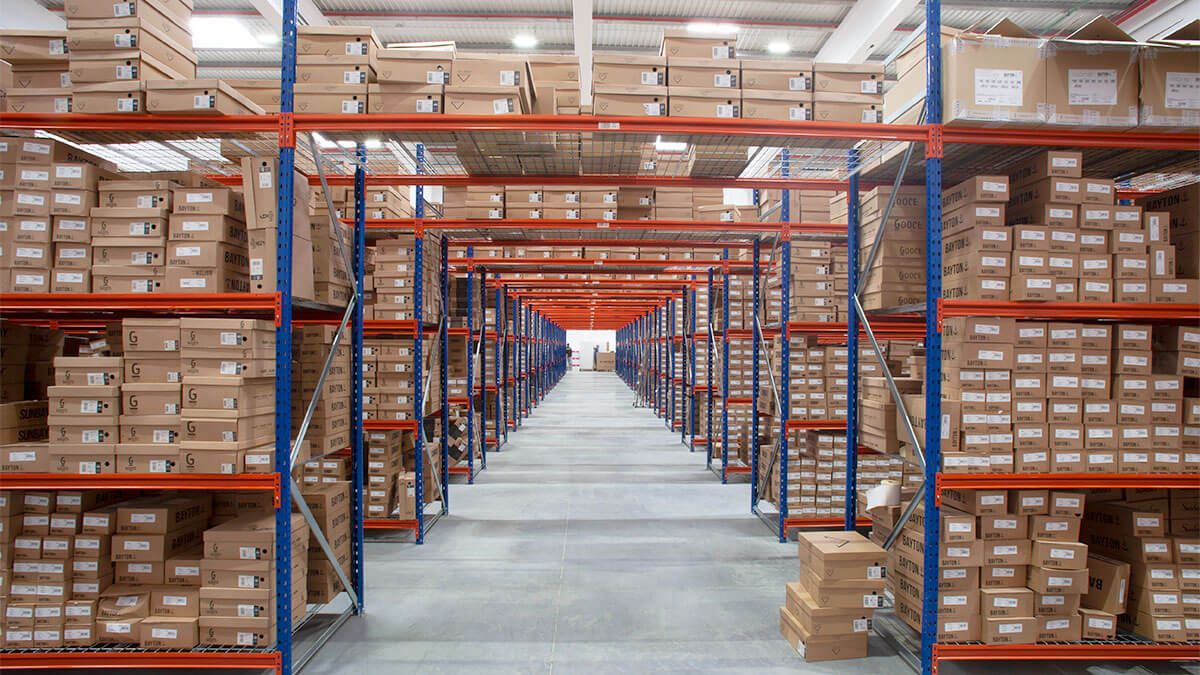

Micro-Fulfillment centres are logistics centres that have become one of the most important supply chain strategies, consisting of developing an order preparation, classification and distribution system with high storage capacity and performance capability, designed and manufactured to prepare orders in the minimum time so as to optimise the cost of picking and bring products closer to the end consumer. In other words, it is a system located at the rear of the outlet and that takes advantage of the physical height of the store made up of narrow aisles. This method uses the most advanced and automated type of technology, in order to adapt to urban spaces and places to be closer to the consumer and, therefore, specialise in the picking and distribution of small orders speeding up their delivery.

Often, they are spaces located in already existing commercial outlets, a small part of which has been converted into a warehouse to solely meet online order demand where deliveries can be made both in the physical store and to people’s homes.

How does Micro-Fulfillment work?

Firstly, the products are processed and checked by fully automated system administration software, integrated in a larger software network. Once processed, the orders are loaded into small enough cartons so that they can be lifted by hand and moved around the warehouse easily. Finally, these cartons are delivered to the company’s Micro-Fulfilment specialists, who pack the orders for customer delivery.

Advantages and disadvantages of Micro Fulfillment

Micro Fulfillment represents a highly efficient and technologically advanced approach to meet growing e-commerce demand and offers a series of significant advantages.

Order delivery speed

Sending orders from Micro-Fulfillment centres tends to improve delivery times because the distance between the order preparation centre and the customer is less.

Improved omnichannel strategy:

Decentralisation allows you to prepare and organise more complex orders, developing an omnichannel strategy, where the same product can be delivered or returned by different means, in order to manage orders more efficiently.

Lower logistics costs

Closeness to the customer helps to reduce transport costs. These logistics centres also allow greater optimisation of spaces as they are adapted to the existing space to reduce the size and cost of the occupied area.

Improved consumer satisfaction

Managing to send the right product to the right customer on the same day or the day after the order increases consumer satisfaction. The Micro-Fulfillment strategy ensures this objective is met.

However, this new trend also has several disadvantages that companies must consider when opting for a Micro-Fulfillment method:

Higher investment

Operating in a Micro-Fulfillment centre requires financial investment. Often, many companies and organisations do not have sufficient resources to be able to configure a centre with these characteristics. Besides which, to the original investment would need to be added automation and software improvement costs.

Selecting the ideal location

The location of the centre is a key factor. If the location chosen does not help improve delivery times, it will be a waste of time and money. It is vitally important to carry out an analysis to ensure that the new location of the centre will meet the proposed objectives.

Limited storage capacity

Although these centres optimise space, it is true that they are not characterised by having a large storage capacity.

Most appropriate storage systems

Each Micro-Fulfillment warehouse and distribution centre will have specific needs and characteristics that must be previously analysed to define the most appropriate storage systems.

We present below some of the types of industrial racking the best adapt to the characteristics of Micro-Fulfillment warehouse operations.

Longspan Shelving solutions

This system enables immediate access to the unit loads and references stored, with the possibility of adding accessories such as platforms, meaning that Manual Picking Solutions can grow in height without losing functionality. Therefore, they are an optimum system for the manual storage of small and medium-sized products.

Carton Live Storage system

This solution is used in warehouses to make order preparation of small items or light cartons more efficient, as space saving and better control of stock turnover is achieved. It is therefore an unbeatable storage system when we need to manage many products with a high level of turnover.

Multi-tier Shelving

Multi-tier Shelving is a manual storage solution that optimises height space, doubling or sometimes even tripling the warehouse space. It also improves order preparation efficiency without having to automate these operations.

Miniload

The Miniload automated system is the optimal solution for the storage of light and small size products with a high turnover of stock. It is also a high-density solution due to the reduced number of work aisles and optimum use of surface area and height.

Automation: one of the keys

Micro-Fulfillment centres are small logistics platforms within already existing distribution chains. They are focused on serving the online channel and the complication lies in deciding on the SKUs that the stock will have, the quantity necessary and the ability to respond immediately.

The implementation of warehouse management and control technologies and software help to optimise the resources necessary to meet demand. These types of technologies, such as RFID, are able to predict the number of expected orders based on history to ensure the highest possible efficiency.

At AR Racking we have an extensive catalogue of storage solutions that adapt to any space. Contact us if you would like personal advice on the design or installation of your warehouse.