There are different methods for storing products, from stacking pallets on the floor to using adjustable pallet racking or more advanced storage systems. The various types of industrial storage systems enable far more efficient storage management by making the most of the available space and facilitating other logistics tasks associated with inventory management.

In a warehouse or distribution centre that manages multiple products, it is best to store each type of goods with the most appropriate storage system. The choice of this will depend on variables such as the characteristics of the goods, their dimensions and their rotation.

We review below the different types of storage systems, and their main advantages and characteristics.

What are industrial storage systems?

A storage system is designed to optimise the arrangement of goods or products on racking or structures, to make the most of the available space. This approach allows a greater number of products to be stored in reduced areas and heights, improving space efficiency. The racking systems are separate structures to the building, although they can be fixed to its structure using floor, wall or ceiling anchors. This structural independence ensures greater flexibility and adaptability in the organisation of the warehouse.

Racking can be classified in various ways, but one of the simplest is to divide it into two categories: direct access racking and compact racking. Direct access racking provides complete access to each unit of goods, facilitating storage, retrieval and order preparation tasks. This category is ideal for warehouses that handle a wide variety of products and require immediate accessibility.

By contrast, compact racking is designed to maximise space efficiency, allowing greater storage capacity over a particular area. This type of racking is especially useful in situations where space is limited and storage density is a priority.

The choice between direct access racking and compact racking will depend on a company’s specific needs, considering factors such as product variety, frequency of access to goods and space limitations.

Main functions of the storage system

The primary functions of the storage system focus on maximising the use of available space in the warehouse. However, these functions are closely linked to logistics and warehouse management operations, including:

- Efficient reception of goods.

- Effective recording of both inflows and outflows of products in the warehouse.

- Safe storage of products, guaranteeing optimal conditions for their preservation.

- Agile dispatch of goods between different areas of the warehouse, facilitating classification, selection and packaging tasks.

Tipos de sistemas de almacenamiento en un almacén

Los sistemas de almacenamiento pueden diferenciarse en función del tipo de carga que manejan, siendo las principales categorías las cargas paletizadas y las cargas manuales.

Las cargas paletizadas se refieren a mercancías que se almacenan sobre palets y requieren equipos mecánicos, como carretillas elevadoras, para su manipulación.

En contraste, las cargas manuales implican productos que se manejan sin asistencia mecánica, generalmente debido a su menor peso o tamaño.

Types of storage systems for pallet loads

Pallet racking is the ideal solution for warehouses that handle pallet loads with a wide range of references. They allow direct access to each pallet without having to move others, since each space is intended for an individual pallet. This arrangement enables precise stock control.

This type of racking is designed to store loads of different sizes, weights and shapes.

There is a wide range of racking for pallet loads:

Adjustable pallet racking (AR PAL)

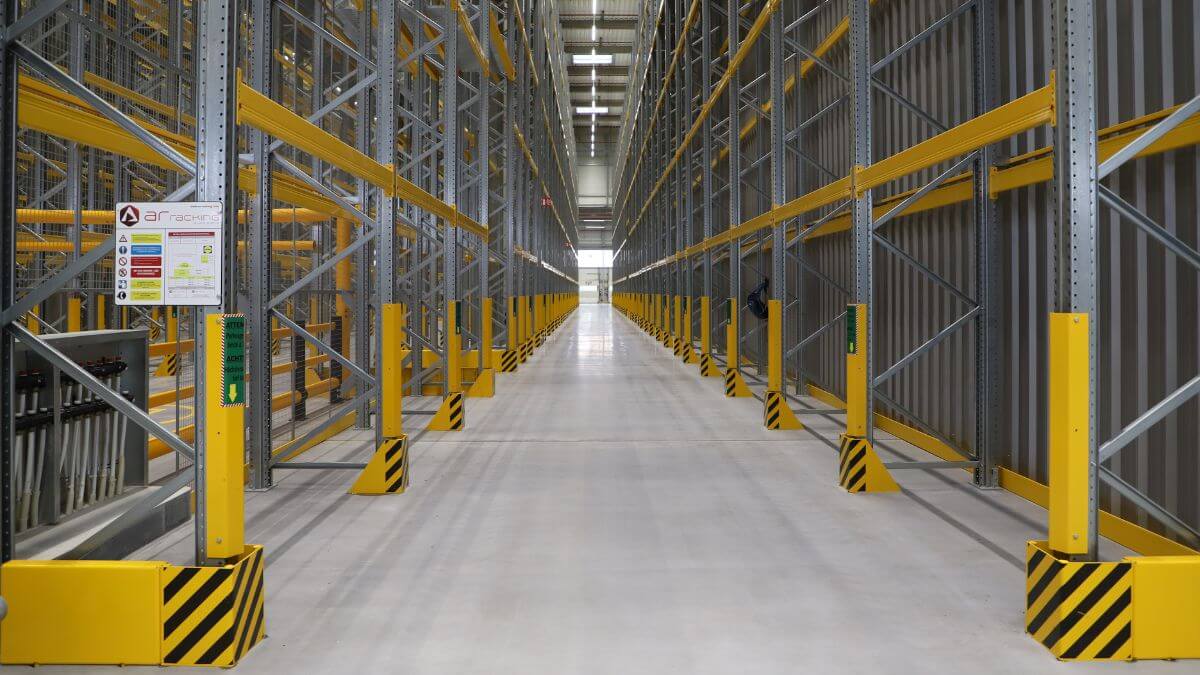

Adjustable Pallet Racking is a type of racking designed for storing pallets mechanically and functionally using forklifts. These forklifts access the goods through aisles that run in parallel to the racking.

Adjustable pallet racking for pallet loads is a logistics proposal adaptable to the dimensions of the unit load and the forklifts.

VNA Very Narrow Aisle (pallet) racking

VNA (Very Narrow Aisle) racking is an adaptation of standard adjustable pallet racking, but compacted into a smaller area. This creates a high-density storage system that allows you to increase warehouse capacity without expanding the space.

Double deep pallet racking

Double deep pallet racking is a storage system that is halfway between adjustable pallet systems and compact high density storage systems.

Drive In Compact Pallet Racking Systems

Drive In compact pallet racking offers a high-density storage solution which fully optimises the available space and height of the warehouse by reducing the work aisles of the forklift.

Mobile Pallet Racking (AR Mobile)

AR Mobile pallet racking is a system where the pallet racking is placed on chassis or mobile bases guided along fixed rails on the floor.

Live Storage for Pallets (FIFO)

The Live Storage for Pallets system (AR Live Storage) is the best solution for those who need to control stock turnover and exploit the available space to the full.

It consists of a compact structure where each level has linear roller beds that allow the unit loads to slide easily thanks to a slight incline.

Push-Back Live Storage Racking (LIFO)

Push-Back LIFO racking is a live storage system for accumulation of pallets, just like the AR Live Storage system, but designed for LIFO type load management (last pallet in, first pallet out).

AR Shuttle for pallets

The AR Shuttle, also called pallet shuttle, system is a type of high-density compact storage solution that uses motorised pallet shuttles that transport the load autonomously inside the racking. These pallet shuttles are controlled by an operator thanks to a remote-control system.

Storage systems for light or manual loads

Picking solutions and shelving for other medium or light load goods are storage solutions for manual picking. These manual storage systems generally store non-uniform unit loads.

Longspan Shelving Systems

The Longspan Shelving system allows the manual storage of small and medium-size materials. It is very versatile racking that adapts to all types of unit loads and that facilitates access to products stored directly and immediately.

Multi-tier Shelving

This system is designed for warehouses with limited surface area, but with the possibility of growth in height. The so-called Multi-tier Shelving is a manual storage solution that optimises height space, doubling or sometimes even tripling the warehouse space.

Carton Flow Rack Systems

Carton Flow Rack Systems facilitate the high-density storage of cartons and light products, resulting in space saving and better stock turnover control.

Types of automated storage systems

Another possible way of dividing storage systems is by whether their operation is automated or not.

Automated warehouses are the most appropriate solution for maximising the storage space and for quick and automated access to the different unit loads. There are automated storage systems for both pallets and cartons.

Automated pallet storage systems

Automated pallet warehouse systems are solutions that use stacker cranes or other automated mechanisms to handle loads. They are storage solutions that help fully optimise the warehouse space and provide quicker and more automated access to the various heavy unit loads.

Clad-Rack Warehouses

Clad-rack warehouses can comprise any type of storage system since their main characteristic is that the racking forms part of the structure of the building.

In this system, the racking not only supports the stored load, but also the load of the external enclosures of the warehouse, as well as external forces such as wind or snow.

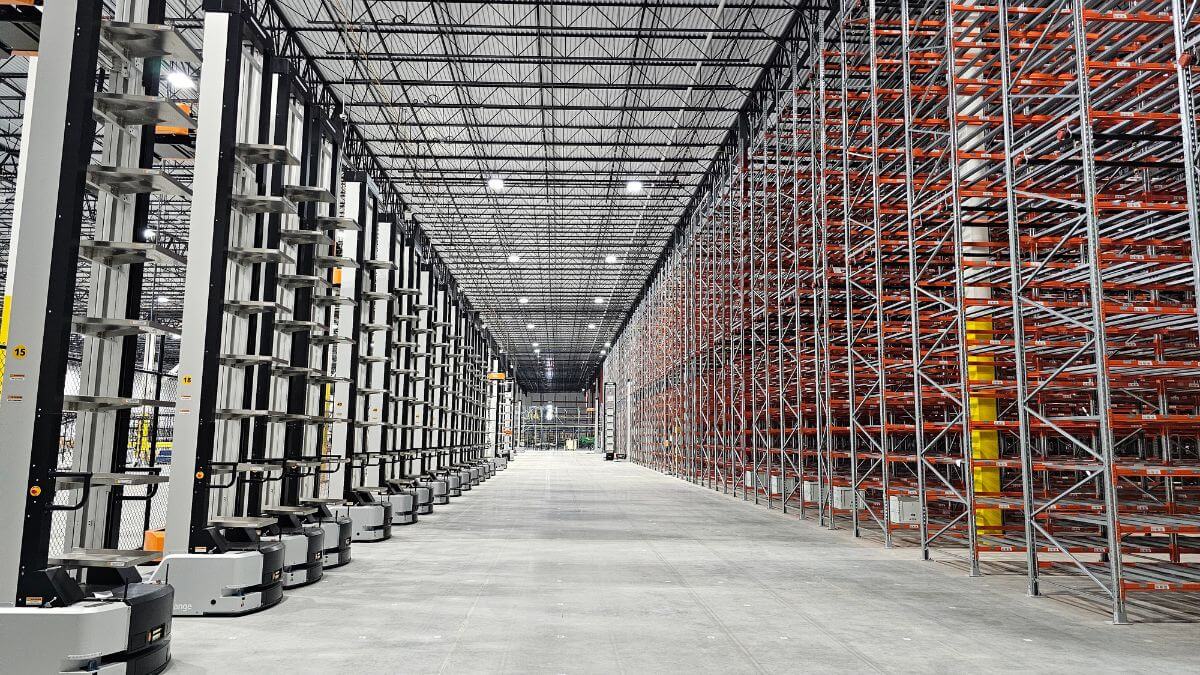

Automated System for Pallets

Automated Storage Systems are solutions that use stacker cranes or other automated mechanisms to handle the loads.

This type of system offers high density storage thanks to the reduced number of work aisles and its storage capacity at height. It also uses minimal response times.

Automated storage systems for light loads

Automated warehouses for cartons are solutions that use stacker cranes to handle light and small loads.

Automated warehouse systems for light loads or cartons are characterised by providing the warehouse with a product-man system in which the picker does not have to move about.

Miniload Storage System

The miniload automated system is the optimal solution for the storage of light and small size unit loads with a high turnover of stock.

This system uses stacker cranes or automated mechanisms to handle loads, enabling high-efficiency and reduced storage time and handling of cartons.

General advantages of the storage systems

A good storage system provides key advantages that positively impact the efficiency, productivity and safety of any logistics or storage operation.

- Space optimisation: makes the most of available space in the warehouse, which reduces infrastructure costs and maximises the storage capacity.

- Efficient organisation: facilitates the orderly arrangement of products, which speeds up their location and access. This helps reduce search times and makes logistics operations more efficient.

- Improved productivity: a well-designed and organised storage system streamlines the processes of receiving, storing and dispatching goods, which increases staff productivity and reduces handling times.

- Inventory control: facilitates precise and updated inventory control, allowing you to know at all times the quantity and location of stored products. This helps prevent losses due to lost or obsolete products, and optimises the stock replenishment process.

- Safety: an appropriate storage system ensures the safety of stored products and of staff who work in the warehouse. This is achieved by using strong and secure racking, as well as through the implementation of accident prevention measures.

Examples of storage systems

These are some examples of our success stories in storage system projects: At AR Racking we specialise in the manufacture, design and installation of industrial storage systems such as these:

Fire Fighting Equipments, S.L.U.: AR Racking has implemented its AR PAL advanced system in the warehouse of Fire Fighting Equipments, S.L.U. in Carbonera de Frentes, Soria.

The installation covered an area of 1,200 m². This strategic change made it possible to increase the storage capacity from 1,500 to 2,640 pallets, providing Fire Fighting Equipments with an optimised space for its manufacturing and distribution of firefighting material.

Renova: AR Racking has manufactured, designed and installed a 100% galvanised solution for the renowned Portuguese paper products firm Renova. The clad-rack structure, whose particularity is that the racking supports the entire building, is completely galvanised and therefore extremely resistant to corrosion and extreme environmental conditions. The warehouse occupies an area of 6,532 m² and is 34 metres above floor level. The warehouse has a storage capacity for 27,360 europallets.

GXO: The US operator GXO Logistics, decided to increase the storage capacity of one of its warehouses in Chile with the help of AR Racking. An adjustable pallet racking solution was installed, which allows for rapid location of and direct access to heavy unit loads.

Criteria for choosing a storage system

The most effective storage system is one that adapts to the specific needs and circumstances of each facility, seeking to maximise profitability. When selecting one, it is important to take into account various aspects such as the planned storage capacity, the number of references and pallets per reference, the available space, the handling equipment available and the budget allocated for this task.

You should therefore consult with an expert supplier to receive suitable advice on the storage system that best adapts to the company's needs and logistics operations.

Contact our team of experts for advice on the matter.