The warehouse is far more than just a simple space to store goods. Good (or bad) management of all operations in the warehouse (receipt and dispatch of goods, preparation of orders, maintenance, storage...) will directly impact the performance of a company or business.

The warehouse must be in a planned and structured place. The first thing to do, after the acquisition of the land and the building, is to prepare an appropriate warehouse design or layout for the business, taking into account the main storage areas. At the heart of everything naturally are the storage systems where the goods are stored. Storage can be at floor level (without any type of installation and support) or on industrial racking, with this being the best option for most loads. However, there are several types of industrial racking for heavy loads, whose characteristics meet different and specific needs.

But… how to choose the most appropriate industrial racking? And how do you know which logistics solution to install in the warehouse or distribution centre?

There is no single and clear answer, but certain criteria should be considered in the adaptation or optimisation process of a warehouse with industrial racking. These are as follows:

Characteristics of the warehouse premises or building:

The dimensions of the warehouse are a determining factor when choosing one storage system or another. That is, the height of the warehouse and surface area should undoubtedly be the first factor to consider.

For example, for a warehouse that is more than 12 metres high, the appropriate storage solution to fully optimise that verticality, and hence the investment, may be a warehouse with racking that not only supports the load but also the external enclosures and that allows the integration of stacker crane type automated systems, as in clad-rack warehouses.

However, for a warehouse with a reduced horizontal surface the priority may be high-density storage to store the maximum number of unit loads rather than direct access to the goods. In such cases, the appropriate storage system would be a compact solution such as Drive In / Drive Through Racking Systems, Live Pallet Racking (FIFO) or Push-Back Racking (LIFO), or Pallet Shuttle Systems.

Type of goods or product to store:

It is assumed that a business organisation thoroughly knows its product and everything related to its marketing. Not all loads can be stored in any industrial racking.

When it comes to size, loads can be small or medium, large or very large. In other words, if the unit loads are cartons that can be handled manually by a person, it is very likely that the racking that best adapts to that load will be longspan shelving or carton flow rack systems. There is also the option of installing adjustable pallet racking systems with galvanised trays or chipboard panels to store individual cartons.

However, if the unit loads are large pallet loads, the various industrial pallet racking options should be considered.

The load may also be very voluminous or long. In this case, cantilever racking is most appropriate for storing these types of goods that may be tubes, beams, etc., very common in outdoor warehouses. In short, knowing the type of load and its commercial management are criteria and factors to include when configuring a storage solution in a logistics centre.

Flow of goods and rotation:

Another criterion to consider when classifying goods, which can determine the subsequent choice and installation of the industrial racking, is stock rotation, since some storage systems favour a faster rotation than others. For example, perishable products or fashion accessories have a very fast rotation, as they need to be despatched in a short period of time so that they do not deteriorate or become obsolete.

FIFO live pallet racking, which has an incline so that the goods can move within the structure, are designed for whoever needs a fast stock rotation and wants to optimise as much space as possible. The same is true with drive through compact racking or pallet shuttle racking systems. All share a key differentiating characteristic: they work according to the FIFO management method, i.e., the first product in is the first one out. There is therefore immediate access to the product to be unloaded.

This does not mean fast rotation is always ideal for all companies or is the objective of the warehouse. Direct access to goods or having industrial racking with greater margin for adaptation in the future may be another option.

Special requirements:

Many goods can be stored in a dry environment in normal environmental conditions, but certain products need the environment in which they are stored to meet very specific conditions so that they do not deteriorate and therefore cause losses. For example, certain items from the food sector, which require a refrigerated or freezing environment or vaccines for COVID-19 and many other pharmaceutical products.

In warehouses with cold stores or freezing chambers, it is very common to find storage systems that enable a temperature uniformity and the circulation of cold air. These warehouses also generally have high density and compact storage solutions to exploit every cubic metre and the energy cost is fully optimised. Further options include mobile racking, drive in racking systems and pallet shuttle racking systems. Adjustable pallet racking is more frequent in refrigerated environments but less so in freezing ones.

The need may also arise to store delicate or hazardous products. For example, when installing industrial racking where chemicals are to be stored, it is important to know especially the chemical compatibility of products. This will indicate the extent to which a chemical can have contact with another without causing corrosion or negative exchanges in their characteristics.

Human and mechanical resources:

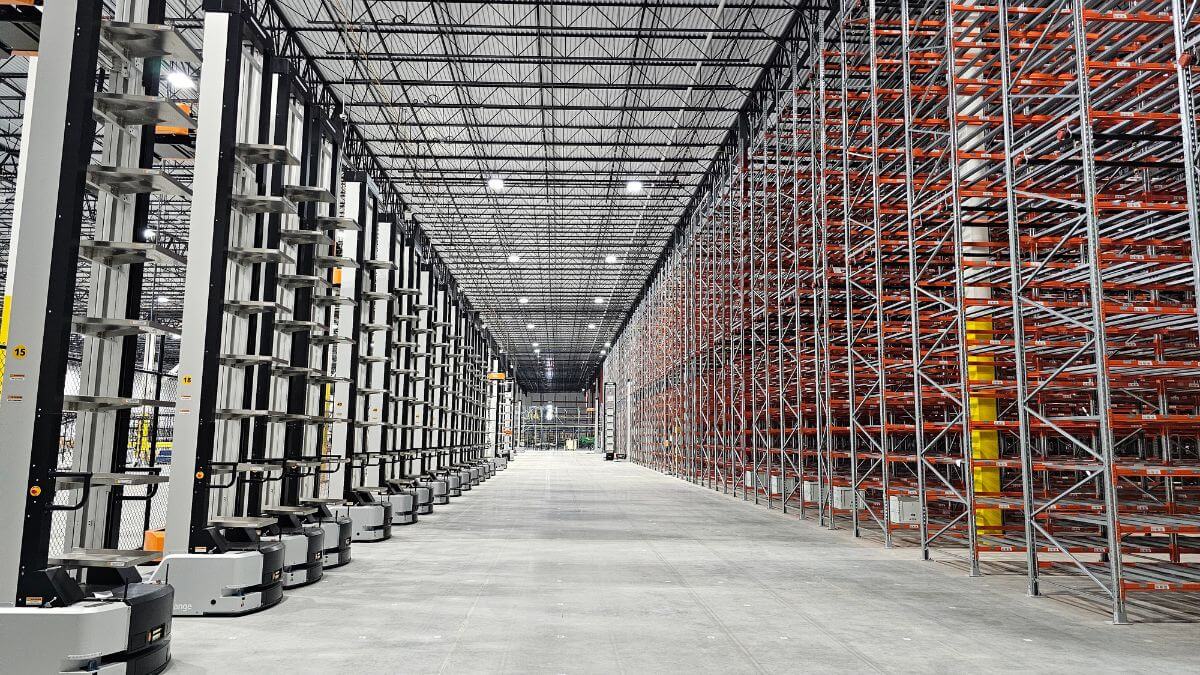

Whether we are talking about a new warehouse or a redesign is being considered, the professional profile of people who work in the warehouse and the mechanical and technological resources they will have at their disposal must be taken into account: forklifts, stacker cranes, etc. Firstly, for the simple matter of operational planning and, secondly, because they are factors that require a certain investment.

For example, the initial investment will not be the same in a conventional warehouse or an automated warehouse (whether for pallets or for cartons as in the miniload system) where the flow of goods will depend 100% on automated machinery.

It will also be necessary to implement staff safety measures and measures for the maintenance and prevention of industrial racking and mechanical resources, to help avoid any accident and also extend the useful life of the storage systems.

If you are considering installing industrial racking or redesigning your warehouse to fully optimise your space, please contact us here and our team will advise you on the most suitable solution.