Automated warehouses, whether for pallets or for cartons, are warehouses, whose operations are largely or completely mechanised and automated. These warehouses are characterised by taking full advantage of the surface and height space, improving efficiency and maximising productivity.

The automation process of a warehouse can be applied in different processes and areas of a warehouse; it does not necessarily and exclusively have to be in the storage system of the warehouse.

How can a warehouse be automated?

There are three scenarios that have created or are creating a context in which it is necessary for a company to consider an automation process in its warehouse.

Firstly, logistics, especially since the emergence and rise of e-commerce, has undergone a major transformation process characterised by the demand for increasingly shorter delivery times and with less margin for error in deliveries. Automation speeds up processes and reduces the margin of error caused by the intervention of an operator.

Secondly, in those warehouses in which order management becomes increasingly complicated, either due to the increase in demand that will increase the frequency or due to the variety in the type of orders. Transforming certain manual processes into mechanical ones can greatly simplify the complications arising from the situations described.

And thirdly, for whatever reasons, the good performance of a company and therefore the increase in demand for its products or goods can lead a company to consider the need to expand the surface area or human resources of the warehouse. However, there may not be enough floorspace available or its cost is very high, or increasing the headcount is not possible. In such cases, and although the initial investment may be higher, warehouse automation may be the alternative.

What are the advantages of warehouse automation?

The positive aspects of automation are:

- Improved productivity by increasing the speed of logistics processes and improving the precision of order handling and control.

- Solving the shortage of storage space for expansion without sacrificing maximum space optimization.

- Reduced risks for personnel as their sphere of action is reduced.

- Maximum reliability in the operation.

- Rigorous stock control.

What are the challenges of automating warehouses?

The advantages of automated or semi-automated warehouses are numerous, but it is a process that poses certain challenges such as:

- The initial investment can be high.

- Automation requires control and maintenance.

- The options of flexibility or adaptation of the warehouse to future logistics needs are reduced since the modification in the processes is more complex.

Therefore, it is essential to carry out a prior exhaustive analysis to establish warehouse automation needs and objectives. Factors such as the time available for implementation, a good understanding of the expected productivity and the budget available must be taken into account.

Automation in the different areas of the logistics chain

A warehouse can be automated in one or more phases of the logistics chain of the warehouse, such as the packaging processes, the preparation of shipments (picking), the goods storage system and the control of warehouse stock.

1. Automation in the reception area:

The conveyors or conveyor belts automate the path of the load at the moment of unloading. This is very basic automation.

2. Storage system automation:

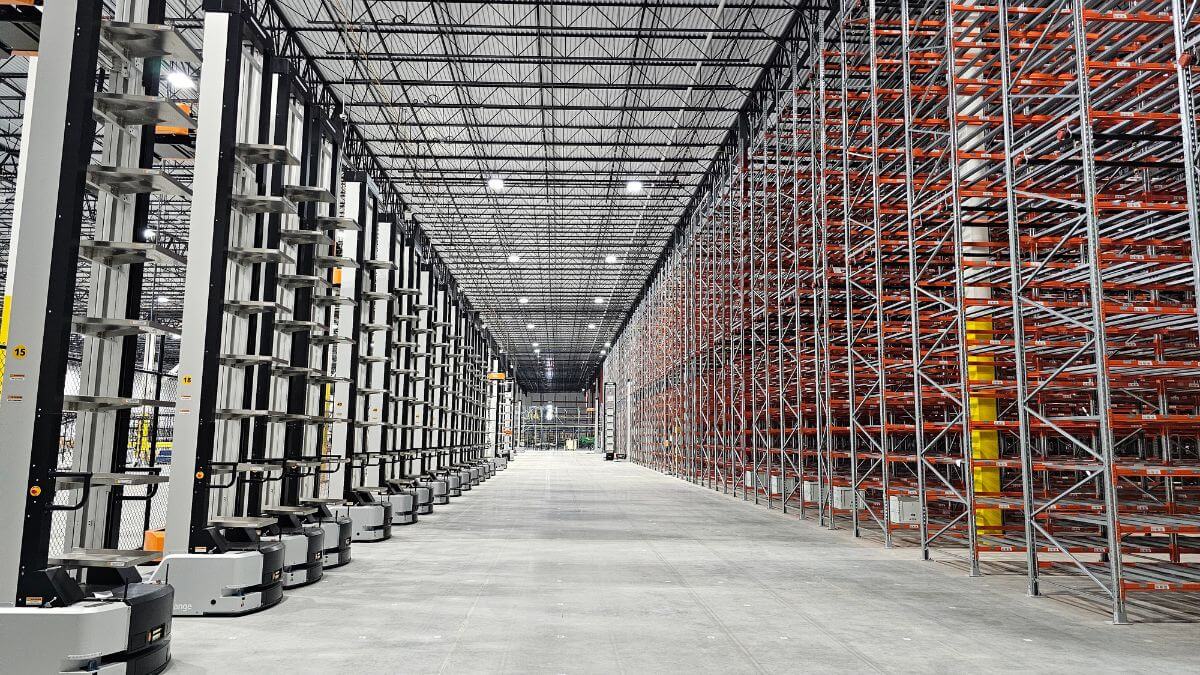

The place where the goods are to be stored is of particular importance in the warehouse. There are automated solutions for pallets or cartons and semi-automated solutions.

Automated warehouse for pallets:

Automated pallet warehouse systems use stacker cranes or other automated mechanisms such as the conveyors to handle the loads. It offers high density storage thanks to the reduced number of work aisles and its storage capacity at height. It also uses minimal response times. Automated storage structures can either be single or double deep.

Automated clad-rack warehouse:

Clad-rack warehouses are automated warehouses which can comprise any type of storage system since their main characteristic is that the racking is part of the structure of the building. In this system, the racking not only supports the stored load but also the load of the external enclosures of the warehouse.

Most of the clad-rack warehouses are equipped with automated systems and robotic equipment to handle the goods, particularly if they are very high. They can either be single deep, double deep, or multideep shuttle (which operates with fully autonomous pallet shuttles that move through the racking to move the unit loads).

Automated warehouse for cartons or miniload:

The miniload automated system is the optimal solution for the storage of light and small size unit loads with a high turnover of stock. This system uses stacker crane automated mechanisms to handle the loads.

It is a semi-automated compact pallet storage solution that uses motorised pallet shuttles that autonomously perform the movements inside the racking. It is not a fully automated solution because it is the operator with the forklift who deposits the shuttle on the required rail, where the shuttle does operate autonomously with the load.

3. Order preparation mechanisms:

There are numerous alternatives for the warehouse order preparation area to improve the speed and precision of this phase:

- Voice preparation: instructions are given to a preparer through a vocalisation system that transcribes the verbal instructions of the management system. This allows you to keep both hands free, giving you freedom for other tasks.

- Pick to light / put to light: a light installed on the racking turns on to indicate to the operator where the products must be collected or placed.

- Goods to man picking system: the goods are sent directly to the operator responsible for finalising the order preparation. In the main order preparation system of automated storage and picking systems, the stacker cranes pick up the product and transport it to the operator.

4. Automated Packaging:

Some simple options that can greatly streamline the logistics chain process:

- Resources for filling cartons: paper filling machines, air filling systems and foam filling systems for safe filling.

- Machines to secure the goods: they can be machines that wrap pallets with film, machines that close cartons with adhesive tape or machines that strap the products.

- Mechanisms for closing the orders in cartons: for example, sealers.

Modernisation and investment in automation technology can be a differentiating factor for the smooth running of a company. It is a high cost investment, so it is important to establish and study the specific needs and objectives of the company.