Cold product storage has been at the heart of conversations in the logistics sector in recent times. It also has specific logistics characteristics that mean the design of solutions have to be fully adapted to the maintenance of the cold chain, but without forgetting the profitability of the warehouse and energy efficiency and sustainability.

In addition, the current public health situation has fostered the growth of a sector already on an upward trajectory. It is calculated that the consumption of refrigerated and/or frozen products has increased 10% since the outbreak of the pandemic.

All this means that refrigerated food storage facilities are complex and require very specialised warehouses. In short, cold storage has been facing short and medium-term challenges for a while, which it must now address, particularly in the food and pharmaceutical sectors.

4 Challenges that a Cold Storage Warehouse must face

Companies dedicated to the storage or distribution of refrigerated or frozen products must face four major challenges when designing or choosing the warehouse and industrial racking that will store the load in refrigerated conditions or in freezing chambers:

1. Search for volume optimisation:

The evolution of consumer habits has meant that the logistics real estate sector is confronted by growing demand for increasingly higher priced floor space. Every cubic meter costs money, both in terms of the initial investment and operations, so the main objective is to optimise the volumetric space of warehouses.

2. High level of customisation of facilities:

From construction to needs, working with the customer on the definition of the building and also on the design of the cold stores or freezing chambers. Firstly, because refrigeration and freezing are not the same, they require different temperature levels (>0º and <0º, respectively)

3. Efficient coordination in executing the turnkey project:

Especially in projects that require a minimum of civil engineering work such as in high-bay storage systems like clad-rack warehouses, very common in the cold storage sector, as shown by the warehouse for frozen products of the Virto Group.

4. Energy efficiency:

The warehouse must be productive and profitable, so there should be no abrupt increases in energy expenditure any more than necessary. Cold storage facilities can account for up to two thirds of the total energy consumption of cold stores in general and can represent a quarter of the total general costs of companies that store cold products.

Energy efficiency should not only meet expenditure criteria, but also consumption and respect for the environment criteria to mitigate the impact of climate change and its consequences.

3 Essential Characteristics of Cold Storage Racking

Industrial racking, the warehouse and its cold store are just another element in the complex cold chain process, but they must meet very specific criteria otherwise they could ruin the cold chain and therefore render inoperative the warehouse and the company’s operations in general:

1. The storage system: utilisation of space and homogenisation of temperature

The industrial racking that will be installed inside the cold store or freezing chamber has to fully exploit the storage capacity of the space without losing sight of ongoing maintenance and homogenisation of the temperature. Racking must in no case block the cold atmosphere.

2. The steel of the racking systems: corrosion resistant

The steel of the racking systems must be prepared to work at extreme temperatures and be corrosion resistant for two main reasons: so that the storage system does not deteriorate or affect the product or goods. Industrial racking manufactured with galvanised steel is the most resistant in these types of environmental conditions.

3. Compact and high-density solutions:

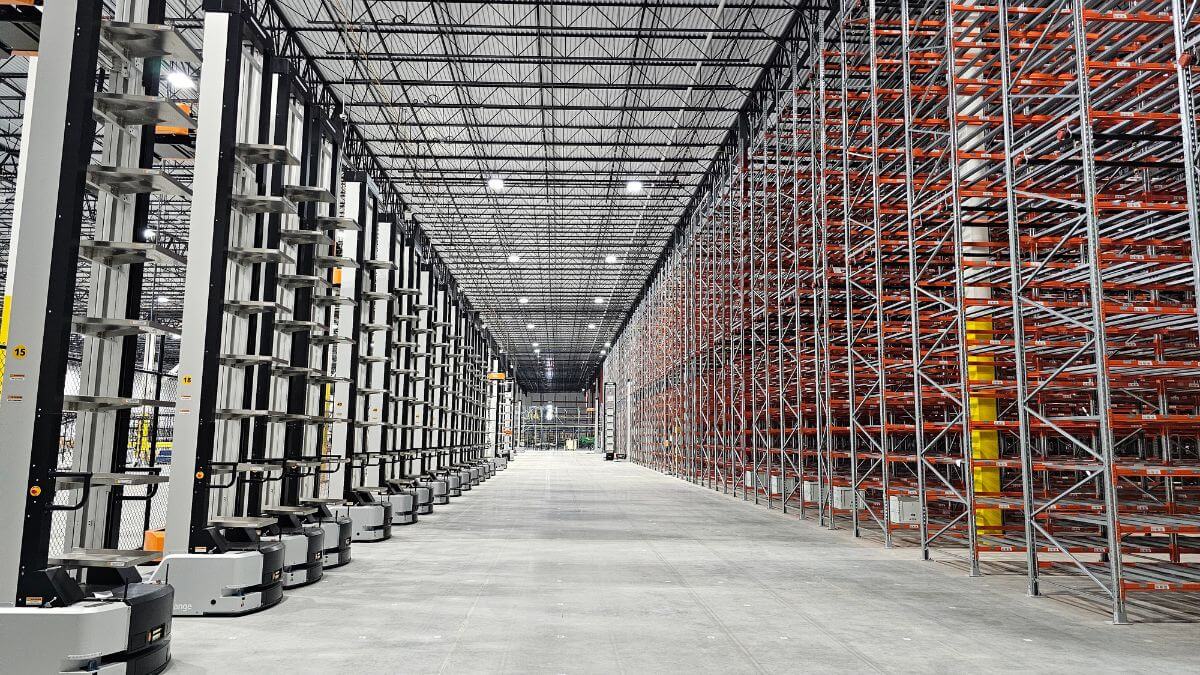

Mobile pallet racking, semi-automated solutions for moving the load such as the Pallet Shuttle system, the Drive in Racking system or high-volume and high bay clad-rack warehouses are the racking systems that most adapt to cold storage needs, as they enable high-density storage and compact pallet racking, and considerably increase the storage capacity and respect temperature conditions throughout the cold store.

They are all compact pallet rack storage systems that favour a controlled temperature distribution and reduce the volume to cool as they better exploit the available space.

The warehouse supply cost saving and reduced loading and unloading times are aspects that must also be considered when designing industrial racking for cold environments. However, this need must be fulfilled in any storage project, whether in cold systems or in conventional warehouses.

Agile operations: beyond automated solutions

Sometimes flexibility and customer tailored solutions are talked about; however, there is still a feeling that automation is the only option and that it also requires major investment.

Automated warehouses using stacker cranes or clad-rack warehouses are fully automated and advanced logistics projects that enable great volumetric and height densities. However, there are other semi-automated solutions.

Semi-automation using pallet shuttles or incremental projects using mobile racking with options of adapting to future needs can be the key for many cold chain logistics players. These are two of the most common storage systems for cold conditions. Here are some success stories:

Cold storage with pallet shuttle racking success stories:

Warehouse for AUTAA:

- Company sector: corporation specialised in industrial elevation and transport services for heavy loads.

- Warehouse area: 5,000 m2

- Total storage capacity: 6,100 pallets.

Warehouse for Virto Group:

- Company sector: production and distribution of frozen vegetables for retail, food service and industry.

- Warehouse area: 4,660 m2

- Total storage capacity: 10,520 pallets.

Cold storage with mobile racking success stories:

Warehouse for Fandicosta:

- Company sector: producers of frozen, chilled and pre-cooked wild fish.

- Total storage capacity: 12,184 pallets.

Warehouse for Congelados Sariego:

- Company sector: distribution of frozen products.

- Warehouse area: 23,000 cubic metres.

- Total storage capacity: 3,240 pallets.

If you are considering the installation of a new storage system in your warehouse or thinking of renovating the facility, please contact us here and our team will advise you on the most suitable solution.