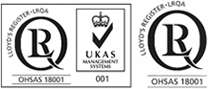

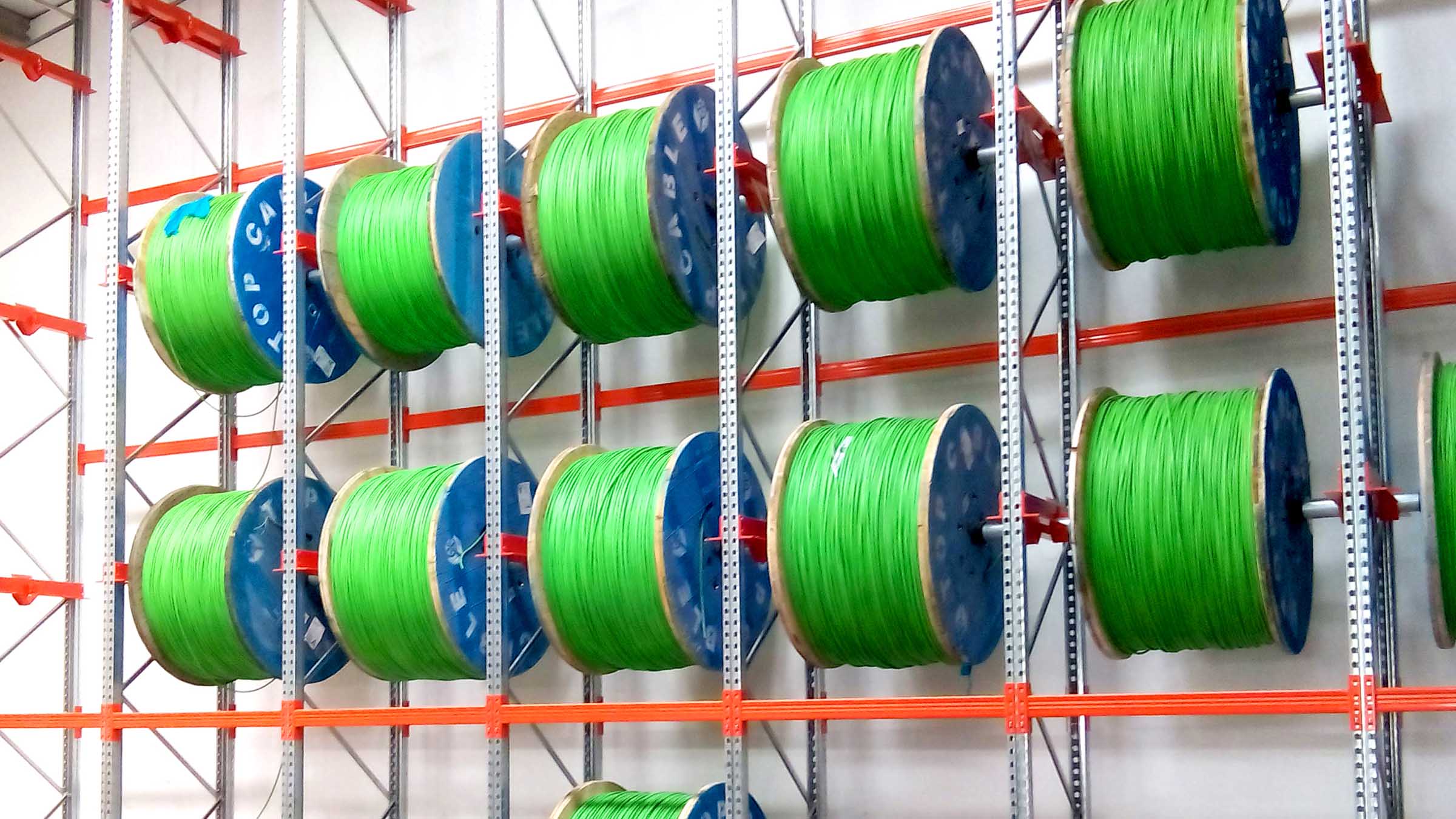

Coil Racks

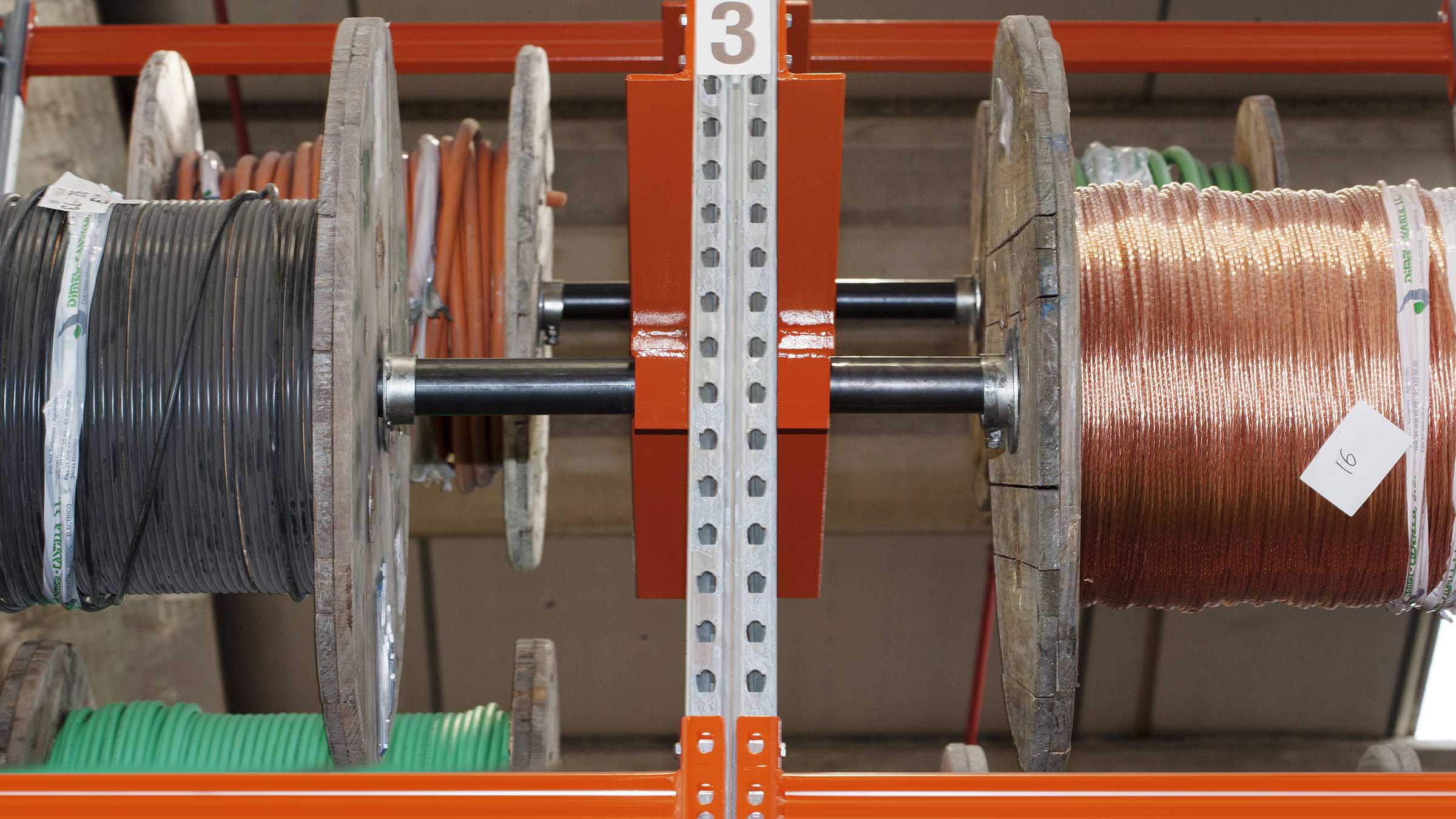

Coil Racks or Coil Supports permit the simple storage of any material rolled in coils (Cable, rope, cloth, etc.).

These shelves with reel stands stand out for their robustness and versatility, allowing optimal organisation in any industrial storage space.

The reel stands are built with high quality materials that guarantee their durability and resistance, supporting the weight of the reels without compromising their integrity.

This storage system is mounted on a adjustable pallet racking structure which is adapted with specific supports for the storage of coils.

The industrial coil racks make adjustable pallet racking more versatile and complement other storage systems.

How does it work?

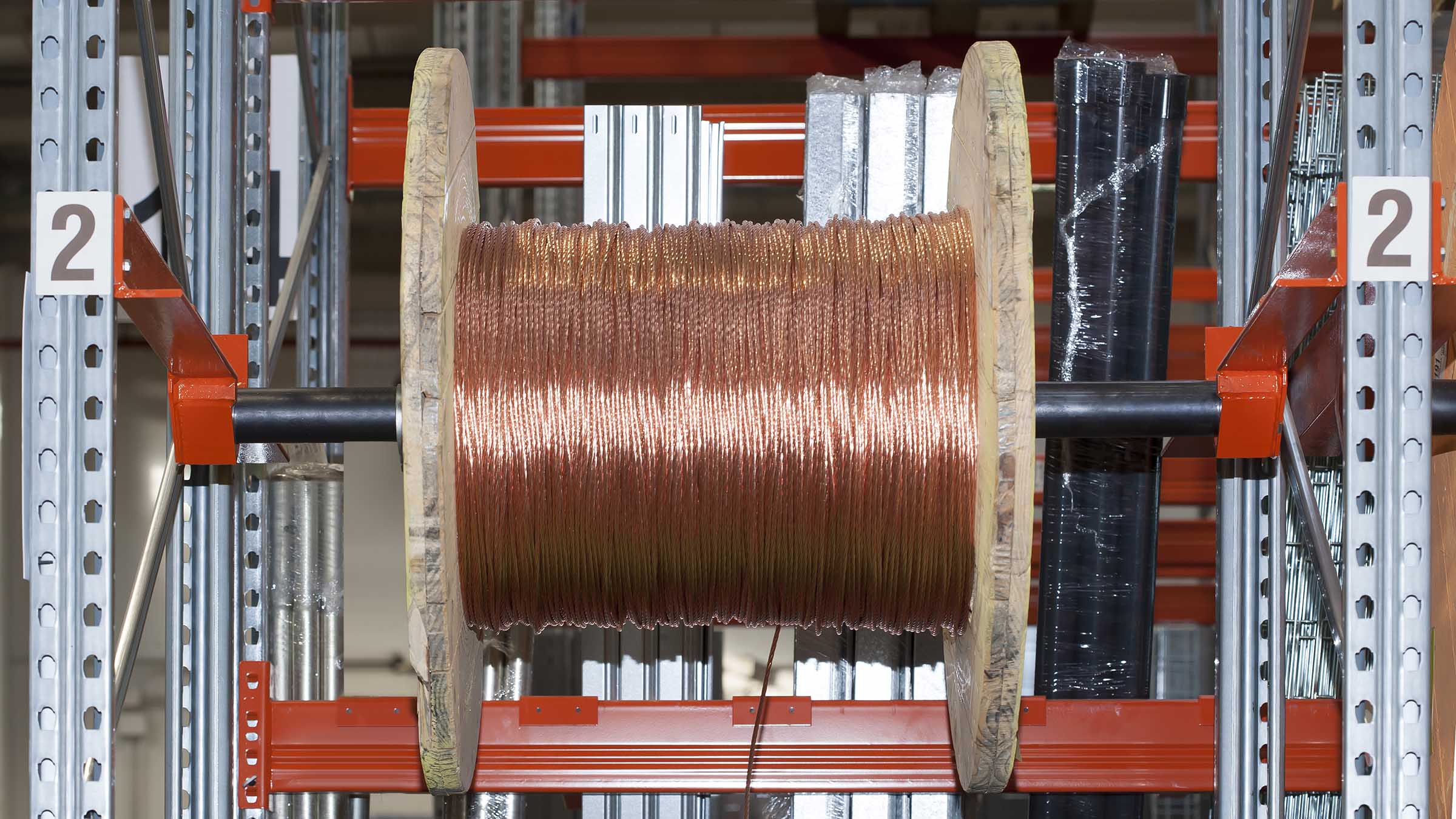

Coil Racks are mounted either on the side or on the front. Both versions require a central metal shaft on which the coils are able to rotate.

While the side coil support is fastened to the sides of the frame, the front support is only attached to the front struts.

Both versions require two pieces mounted in parallel for their correct operation.

Advantages

Coil rack advantages and features

- Industrial coil racks allows direct and immediate access to the goods.

- Assembly, disassembly and replacement of parts is done quickly and easily.

- They are designed to maximise the use of vertical and horizontal space in the warehouse.

- They keep the coils in a safe and stable position, reducing the risk of damage.

Components and accessories

Components of the Coil Rack:

The frames are the main vertical structures that support the entire system. These columns provide stability and support for the other components of the winder.

The beams are horizontal elements that are mounted on the columns. They support the shafts or rollers and allow the positioning and organisation of the reels. These racks can be fixed or adjustable to suit different sizes of coils.

The coils are placed on hanging shafts which are horizontal tubes or bars, which can be fixed or rotating, depending on the design of the coiler. In some models, these shafts have a rotating mechanism to facilitate the removal of the coils.

In some systems, rollers are used to facilitate the movement of the coils within the storage system. The rollers allow the coils to slide easily instead of being lifted.

Quality and security

Coil Racking Systems quality certificates

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE-EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007

- Adjustable Pallet Racking Quality Certificate

- EN 15512

- EN 15620

- EN 15629

- EN 15635

- FEM 10208