Racking Solution for automotive companies

In AR Racking we have long-standing experience in the design and installation of storage systems for the automotive and transport sector.

It is a highly diverse sector in terms of the type of loads to store: bulky and heavy unit loads of the main parts of the vehicle, and small and secondary parts or parts with special characteristics and requirements such as tyres.

For this reason, it is quite common in industrial racking projects for the automotive sector to install a combination of different storage systems to meet the different needs of a company.

AR Racking’s range of uprights and beams for different weights and volumes makes it possible to adapt the system to the specific needs of each company in the automotive sector.

Storage systems for the automotive industry

Priority stock rotation

In the automotive sector, perfect goods rotation is key, which is why it is usually recommended to install systems that allow FIFO-type stock management. In fact, the automotive sector is one of the pioneers in the application of the Just in Time method, which is the ultimate expression of goods rotation.

Direct access is important

Direct access to all unit loads stored greatly helps to achieve perfect stock rotation.

Variety of sizes and weights

The storage systems to be used will vary significantly depending on whether large and heavy automotive parts are stored, or small parts and accessories. It is also a sector with many specific unit loads that cannot be stored on a standard pallet and must be stored in custom-made crates.

Combination of different systems

Due to the wide variety of products to be stored, a solution given for storage projects in the automotive sector is to design and install a combination of storage systems. The options are to choose pallet racking for some products and picking for others, or to combine compact systems with adjustable pallet racking solutions.

Characteristics of the automotive industry

The automotive sector is one of the most important sectors economically worldwide. It encompasses all companies responsible for the design, production or sale of automobiles or any of their parts.

Main global producers

The leading producers are China, United States, Japan and Germany, although there are many international companies dedicated to this sector in any of its production phases.

Constant adaptation

The automotive sector has always required the constant ability to adapt to change and is currently facing major challenges such as the manufacture of electric vehicles, the increase in manufacturing and raw materials costs and the reduction in the purchase of vehicles due to changes in the habits of society.

The storage needs of the automotive sector are very diverse depending on the product to store.

Recommended Industrial Racking:

Recommended storage systems for the automotive sector

Adjustable Pallet Racking

Simplest industrial racking for pallet unit loads. Its main characteristic is direct access to the unit loads and its adaptability and versatility for different types of loads.

Very Narrow Aisle Racking

Very similar to adjustable pallet racking systems, but interesting for automotive companies with less available space to install their industrial racking systems.

Live Storage Pallet Racking (FIFO)

Live pallet racking can be a very interesting solution for automotive companies that store fast-moving items. It is a high-density storage system that optimises available space and works with the FIFO (First in, First out) stock management system.

Tyre racking

If the automotive product to be stored is tyres, the ideal storage system will be the manual picking solution adapted for tyre storage. The system will be adapted according to whether the tyre is stored with or without its rim.

Longspan Shelving

Longspan shelving or manual picking solutions are usually a very common option in the order preparation area of companies that produce parts or components for the automotive sector. It allows access to all the unit loads and their easy location to prepare the order. It is also a very versatile system that can be adapted to the different weights and volumes of the goods.

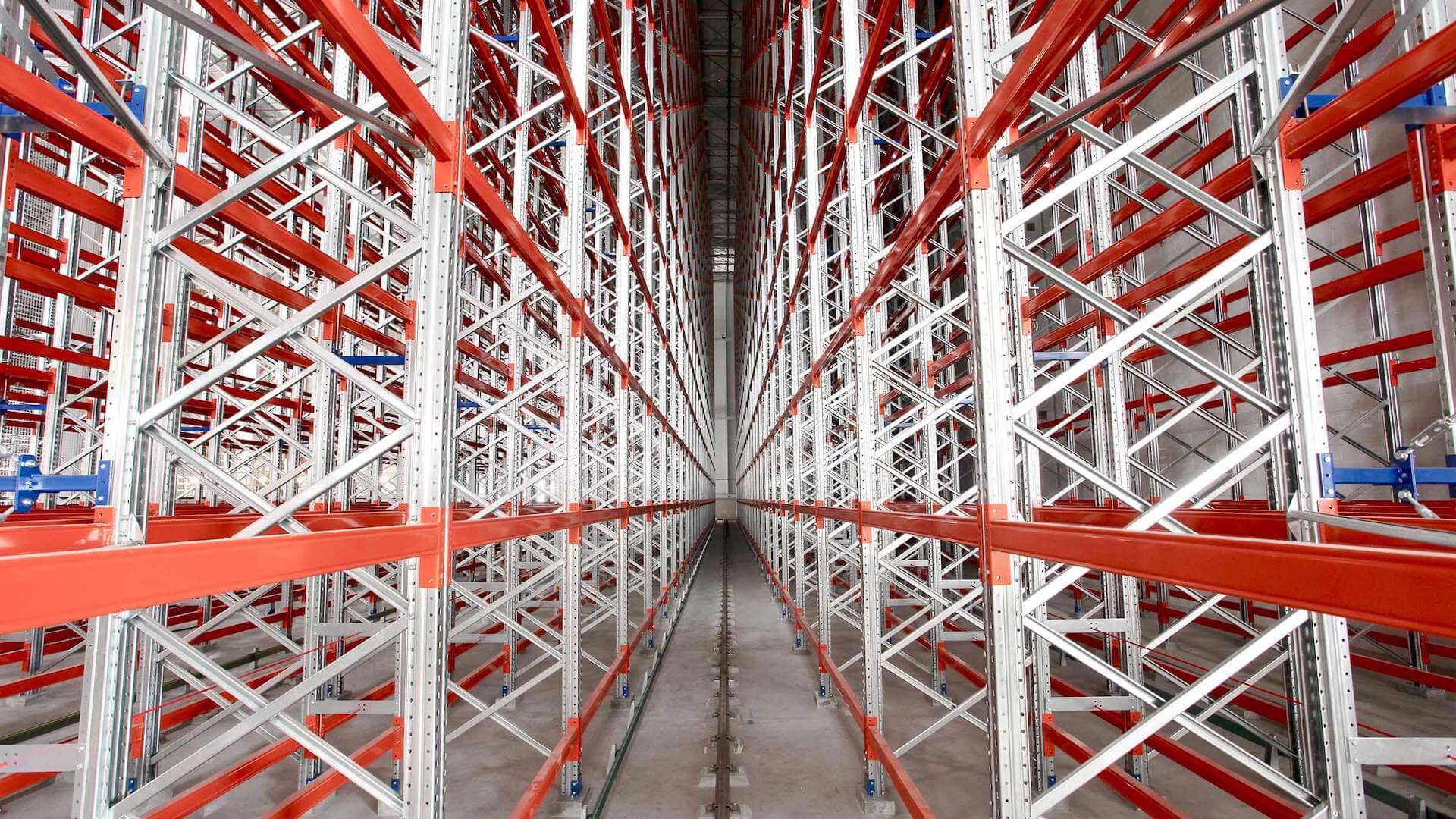

Warehouse with stacker cranes for pallets

Automated storage systems are the ultimate expression of space optimisation and streamlining warehouse operations, but they also require greater investment.