In this publication we describe all the types of existing Live Storage Systems for solving warehouse storage needs.

As a general rule, live storage is a compact storage system that uses the force of gravity to store the unit loads.

There are live storage systems for both FIFO (First In, First Out) and LIFO warehouse management (Last in, First Out).

And also, for any type of load: a solution for heavy loads such as pallets and light loads with systems for cartons.

Before going into more detail on the different types of live storage, it is important to point out that all these live storage systems have clear advantages over adjustable pallet racking systems.

ADVANTAGES OF LIVE STORAGE SYSTEMS:

As a compact and high-density system, all types of live storage achieve great optimisation of the available space.

- There is increased load capacity with respect to an adjustable pallet racking system. Same available space, more storage capacity.

- Loading and unloading times are reduced significantly, as it is not necessary to enter the racking aisles.

- Higher stock flow speed, as the goods are moved automatically towards the exit.

- Reduction in movement times due to fewer aisles. Increased productivity with better use of space.

- Simple product stock control: The possibility of both FIFO and LIFO management facilitates stock management in the warehouse

- Total adaptability. All types of live storage are compatible with other adjustable pallet racking systems, depending on warehouse and product needs.

- Increased operator safety thanks to the elimination of passageway obstructions and the safety measures of the live storage systems.

Having defined the advantages of live storage, we now move on to outline the types of live storage systems, with their description and operation, divided by the type of unit loads: pallets and cartons (picking).

TYPES OF LIVE PALLET RACKING:

Live Pallet Racking (FIFO) – More information here

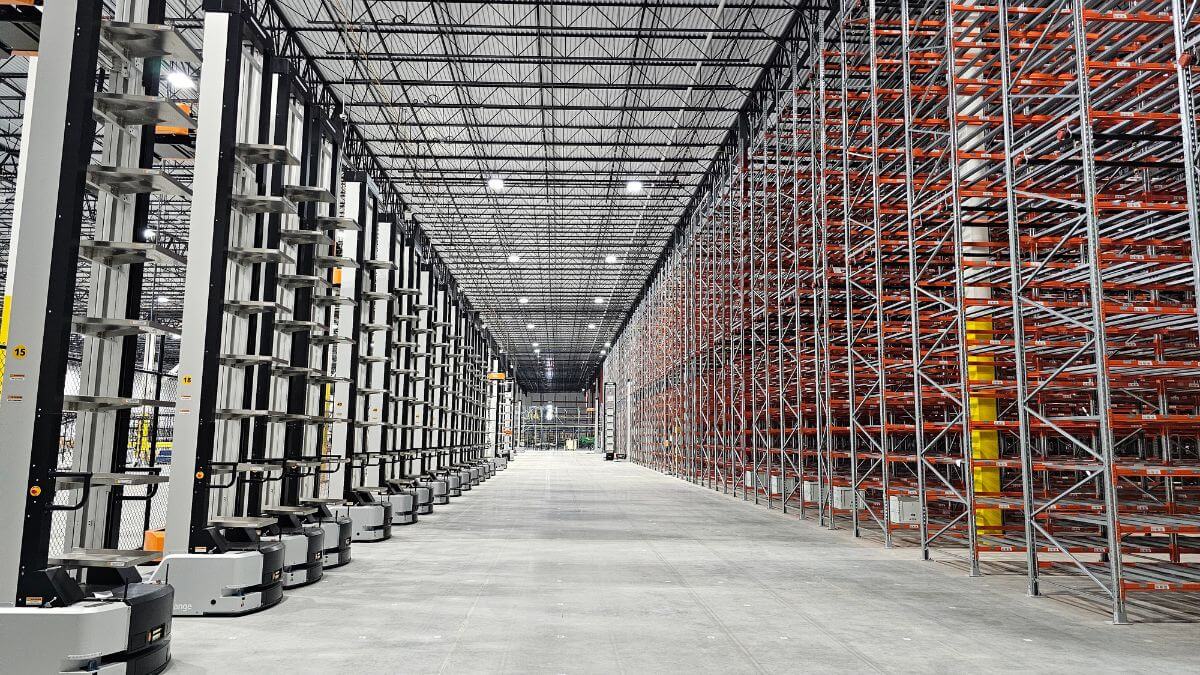

Gravity Live Pallet Racking systems for the FIFO management of the warehouse are possibly the most widely used live system of all the existing options.

This storage system consists of a compact metal structure, equipped with a system of roller conveyors on each level with a slight incline that allow unit loads, generally pallets, to slide freely.

Live pallet racking systems are a FIFO system, so the first pallet in is the first pallet out.

Operation is simple and dynamic, the pallets enter the structure through the loading area, the highest area of the level, and thanks to the incline (4% in most cases) enter the interior of the structure and move along at a controlled speed to the other end, in the unloading area.

The safety of the system and movement is absolutely guaranteed, thanks to the control, braking and protection measures with which the FIFO live storage systems are equipped.

The separate aisles for the loading and unloading make it possible to separate flows and improve the productivity and safety of the transit of vehicles. It is an ideal solution for products with shorter expiration dates.

Explanatory video of Live Pallet Racking system here.

Push-back Pallet Racking (LIFO) - More information here

Push-back pallet racking systems, unlike gravity live storage, are designed for LIFO type warehouse management, where the last pallet in is the first pallet out. In other words, the loading and unloading process takes place in the same work aisle.

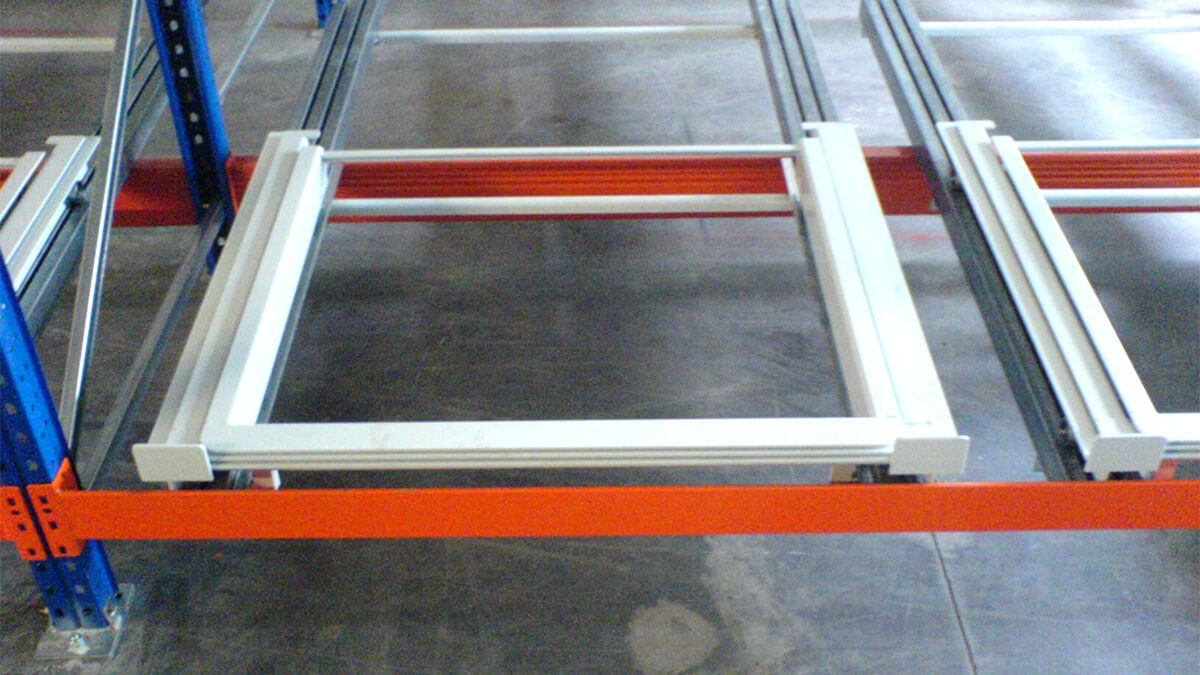

The operation of the push-back pallet racking systems is based on the unit load deposited pushing the previous loads towards the back of the structure, thanks to the system displacement method (rollers or shuttles). For unloading, the slight incline of the rail is exploited so that the pallets slide as they are unloaded.

In short, the pushing force is used for the loading of the pallets and the force of gravity for their unloading.

There are two types of push-back pallet racking systems, depending on the element used to move the unit loads, rollers or shuttles; however, their operation is similar:

- Push-back pallet racking with rollers: the pallets are pushed towards the back of the racking and slide on roller beds with a slight incline.

- Push-back pallet racking with shuttles: in this storage system, the pallets are deposited on a set of shuttles, which are placed on rails with a slight incline.

TYPES OF LIVE STORAGE SYSTEMS FOR PICKING

Carton Flow System - More information here

Carton flow systems, also known as carton live storage, are a gravity-controlled high-density compact system to facilitate manual loading tasks.

It is a similar system to gravity live pallet racking with the same operation with roller beds and FIFO type warehouse management, but adapted for light loads, usually cartons.

The cartons slide on pulley rails from the loading area to the back of the racking, in the unloading area, thanks to a slight incline.

It is the ideal storage system for warehouses with a large volume of picking operations, due to the reduced distance to be travelled by the operators and the time savings in performing operations.

It is a very versatile and high productivity system for the preparation of orders, particularly loose units, allowing for the replenishment of goods without interfering with outward stock movements.

It is also a highly versatile and compatible system with other pallet racking systems.