The FIFO (First in, First out) inventory management method is, together with the LIFO method (Last in, First out), a very widely used tool in warehouse management.

The definition and operation of the FIFO method in industrial storage has to do with the way that goods are moved and is a simple concept: first in, first out. In other words, the first good or unit load to enter the warehouse is the first one out.

Specific industrial storage systems that facilitate this type of process are developed for this, both in operational and management terms.

WHEN IS THE FIFO METHOD USED?

The FIFO method is typically used to manage perishable product stock, with an expiry date, with the most common being food, medicine and cosmetic products.

It is also a common management method for companies that store products that may become obsolete or “go out of style” relatively quickly, such as technological products (home appliances, computers, etc.), footwear and textiles.

The ultimate goal of FIFO is to achieve an excellent stock turnover in the warehouse, giving priority to the output of products that have been stored the longest and can spoil or become obsolete.

FIFO type stock management is not only applicable in a warehouse environment, but is also used daily to manage the product in supermarkets and consumer outlets.

FIFO METHOD ADVANTAGES AND BENEFITS

Carrying out warehouse stock management with the FIFO method has the following principal advantages:

- Perfect stock turnover, which ensures that the first product to enter the pallet racking system will be the first one out.

- Priority to the output of the oldest or obsolete products, or products with the earliest expiry date.

- This prevents the partial or total loss of value of the products stored or their devaluation due to their date of manufacture.

WHAT STORAGE SYSTEMS ALLOW FIFO MANAGEMENT?

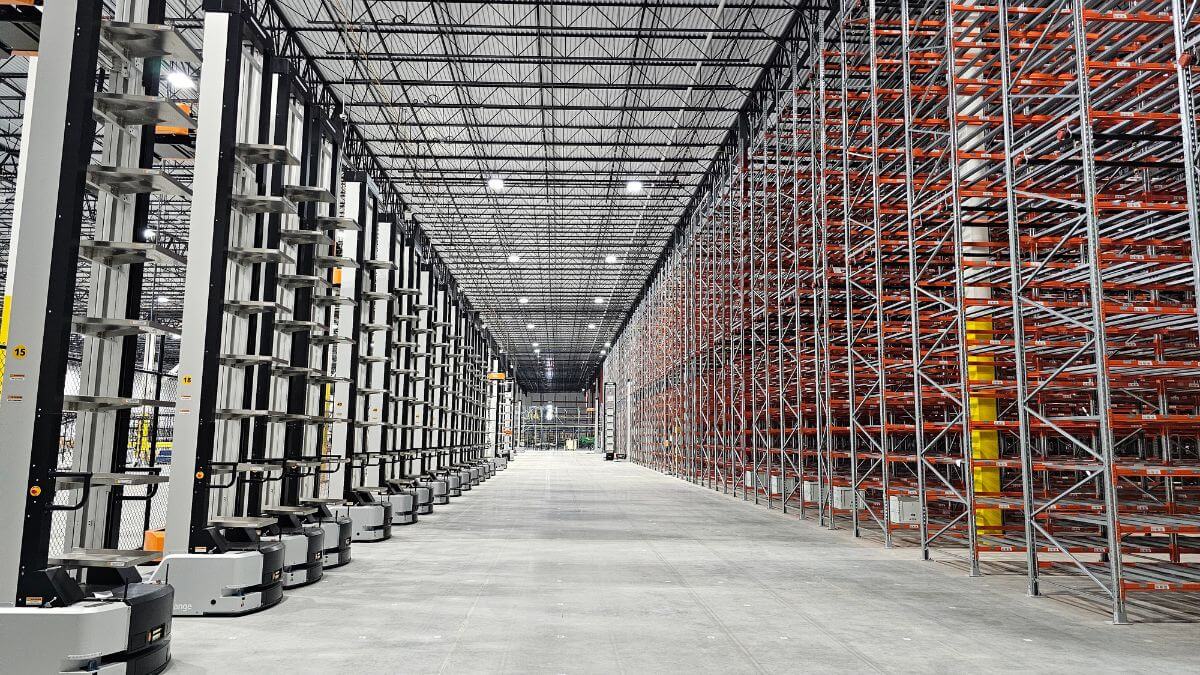

As shown, the use of FIFO warehouse management is widespread, so a series of industrial storage systems especially adapted to this method have been developed.

These pallet racking systems must share a common feature, which is that all of them must have an aisle for loading goods and another for unloading them. In other words, the loading and unloading aisle must be different, as in the case of Drive In or Push-Back systems.

The following storage systems have this common feature which allows warehouse management by the FIFO method:

Live Pallet Racking (FIFO):

- High-density live storage system for pallets. The palletised load moves along a bed of rollers from the loading to the unloading area.

Drive Through - Compact Pallet Racking System:

- Compact storage system which reduces the number of work aisles and which, unlike the Drive In, has an aisle for loading and another for unloading the goods. For the proper functioning of the FIFO method in this system, once the aisle has been loaded and completed, you must completely unload the aisle and leave it empty to begin the loading process again, to ensure that no pallet ends up obsolete.

AR Shuttle racking systems for pallets:

- High-density semi-automatic storage system which uses motorised pallet shuttles that transport the load autonomously inside the racking, from the loading position to the last available position at the back. To implement the FIFO method, you must load the goods on one side and unload them on the other.

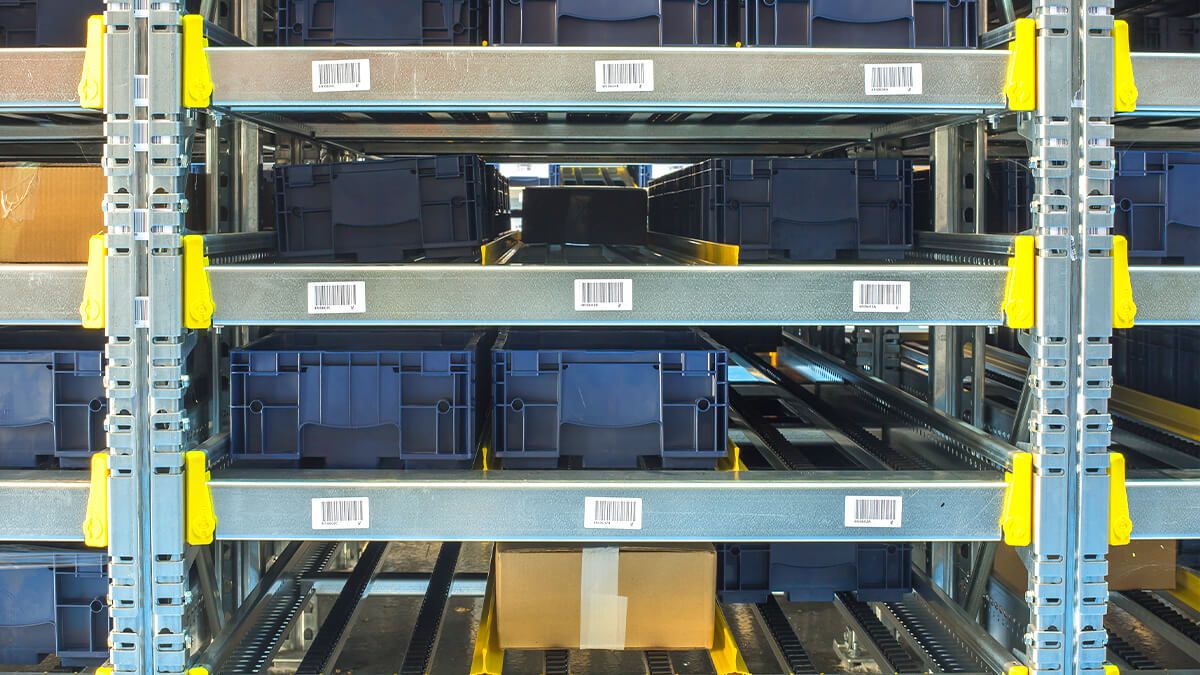

Carton Flow picking system:

- High-density live storage system for boxes and light products. The product moves along rollers from the loading to the unloading area.

If you need any advice on deciding which AR Racking LIFO storage system is best suited to the needs of your company and warehouse, please send us your query here and our professionals will advise you without any obligation.