The storage solutions industry faces numerous challenges: ranging from the type of storage solution that adapts to the requirement of each of the industries, through to how to design and manufacture the industrial racking to extend the useful life of the structures.

The surface finish of the elements that make up the racking will always impact the durability of a storage system or its maintenance, whether due to environmental conditions, contamination from damage caused by improper operation or simply the loss of the coat of paint as a result of non-existent treatment of the steel prior to painting.

We have already talked about the importance of good galvanised steel in industrial racking, so this post will look at the galvanising process and its differences to a paint finish.

What is a galvanising process?

Corrosion is one of the main threats to steel. However, galvanised steel and therefore galvanised industrial racking shows greater resistance to wear and erosion caused by environmental conditions.

As already explained on previous occasions, galvanising is the process of bathing steel in zinc to avoid corrosion and abrasion damage. It should be pointed out that cold galvanising does not exist: this term is quite often used, incorrectly, for zinc rich paints. Galvanising is the reaction between zinc and iron in order to create a solid and stable bond between both metals. That reaction does not exist when zinc rich paints are applied. It is therefore only correct to talk about hot-dip galvanising.

Hot-dip galvanising involves submerging the iron or steel parts or elements to be protected in a bath of molten zinc, maintained at a temperature of 450ºC. At this temperature, a process takes place that gives rise to the formation of zinc and steel alloys on the surface of the parts, like the components of storage systems. However, there are two types of hot-dip galvanising procedures:

Continuous hot-dip galvanising

This is what is known in the market as “pre-galvanised sheet”. It is also an immersion and hot dipping process, but is performed on a sheet which after being galvanised is used to transform and obtain the end products required. Parts that are galvanised using this procedure have a lower zinc coating, of between 15 and 20 microns.

Continuous galvanising is an automated process to obtain zinc coatings on sheet metal or wire, in which the products are continuously immersed in a bath of molten zinc.

Batch hot-dip galvanising

This is the zinc coating of parts that have already gone through the cutting, welding processes, etc. Products galvanised in this way have a zinc protection of greater than 45-50 microns. The thickness of the zinc layer will depend on the thickness of the base layer. The thicker the zinc layer, the more protection the elements will have.

In this procedure, the chemically clean steel is immersed, singly or in batches, in a bath of molten zinc. It is a more manual process.

In any case, it can be affirmed that the galvanised parts of storage systems will have greater durability against any type of internal or external environment thanks to that zinc coating that protects against corrosion.

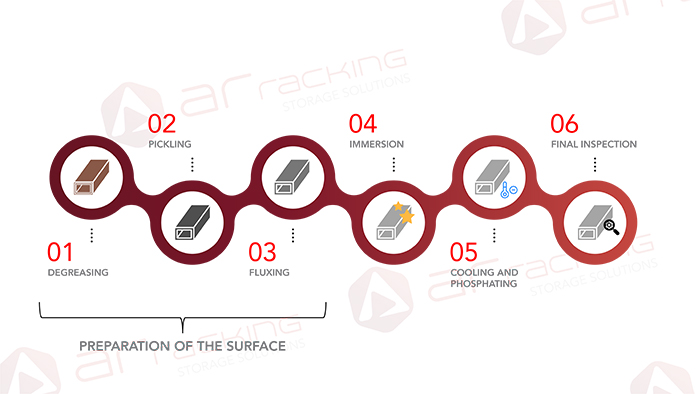

Galvanising phases: how is it performed?

Hot-dip galvanising is one of the technically most advanced steel protection systems. However, the surfaces of parts such as the industrial racking must be perfectly clean before they can be submerged in molten zinc. So, how is this process performed? What phases does it include?

- Degreasing: dirty, greasy or even rusted steel, so the first step is to clean it for a subsequent satisfactory zinc bath.

- Pickling: after cleaning the steel, the pickling phase removes any rust from the steel. Once clean, this steel is placed in a furnace for drying.

- Fluxing: this is the part of the process in which the steel is immersed in a “salt bath”, which will completely seal the surface of the steel and protect it from oxidation.

- Galvanising or immersion in the zinc crucible: the chemically clean steel is introduced into a furnace with molten zinc where both metals will react metallurgically forming intermetallic layers of zinc-iron alloy plus a layer of pure zinc that will protect the part from corrosion.

- Cooling and phosphating: this step only occurs if the components need to be used immediately.

- Final inspection: the newly galvanised steel is inspected, and coating thicknesses are statistically measured. Once everything is correct, the parts are available for dispatch.

Galvanised storage solutions: advantages

The components of galvanised storage systems offer advantages that no other protection procedure can provide:

- Maximum protection against corrosion and abrasion of the industrial racking and all its components: the zinc bath provides cathodic protection for the steel, which means that if the zinc layer is scratched or damaged locally and the steel is exposed, it will be the zinc that absorbs that damage, leaving the steel intact.

- The installation will have a much longer useful life thanks to a high degree of protection.

- Minimum maintenance of the storage system due to its robustness.

- Resistance to all types of environments, including the most extreme.

- Long-term cost reduction due to zero maintenance and there being no need to repair or replace the racking structure.

- Quality control of steel and products fully guaranteed as a result of the exclusive steel treatment for its galvanising process.

- Sustainability: hot-dip galvanising provides the product with a long useful life, resulting in a minimal medium and long-term environmental impact. What’s more, its main components, zinc and steel, are abundant and 100% recyclable, which makes galvanised steel a renewable construction material.

In other words, galvanised storage systems are fully protected against all types of external agents, which is not the case with those types of industrial racking that only have one coat of paint, where corrosion penetrates and directly affects the steel. This results in structural damage and therefore, replacement of parts, increased costs and everything involved in renovating a facility such as a warehouse or distribution centre.

| COMPARISON BETWEEN GALVANISED AND PAINT COATING | ||

| Galvanised coating | Coating with just paint | |

| Coating strength | Zinc alloys with base steel, creating a solid bond | Separate coating |

| Useful life | Very long duration | Variable duration |

| Corrosion protection | Cathodic: zinc will absorb damage in case of corrosion, protecting the steel. | In case of corrosion, it passes through the paint and penetrates the steel. |

| Shock resistance | Excellent shock resistance | Low resistance |

| Abrasion resistance | Excellent abrasion resistance | Low resistance |

| Control of the part | Easy to inspect | Difficult to control its application |

Source: ATEG

Galvanising and painting: duplex system

Although just a paint finish directly on steel does not adequately protect storage systems, galvanised steel allows for a paint coating. This is known as the duplex system: galvanising and painting are combined, increasing corrosion protection approximately twice as long as the combined durabilities of each finishing process.

If you are considering the installation of a new storage system in your warehouse or distribution centre, please contact us here and our team will advise you on the most suitable solution.