Warehouse stock management is a complex task that requires innovative and efficient solutions to ensure maximum precision and speed throughout the process. Automated storage is an advanced solution that optimises the use of space, reduces waiting times and improves efficiency in inventory management.

There are different types of automated warehouses that are classified according to several criteria. By type of load, they can either be light or heavy loads; by storage density, differentiating between high- and low-density systems. They can also be classified according to the warehouse structure, such as clad-rack or adjustable pallet racking systems. Another criterion is temperature, with temperature-controlled warehouses or cold stores. These factors make it possible to adapt the automated warehouse to the specific needs of each logistics operation.

What is automated storage?

Automated warehouses are the ideal solution for maximising the profitability of the storage space and for quick and automated access to the different unit loads.

These automated storage systems, for both pallets and cartons, not only optimise space, but also greatly improve efficiency and reduce work times.

Types of automated warehouses in logistics

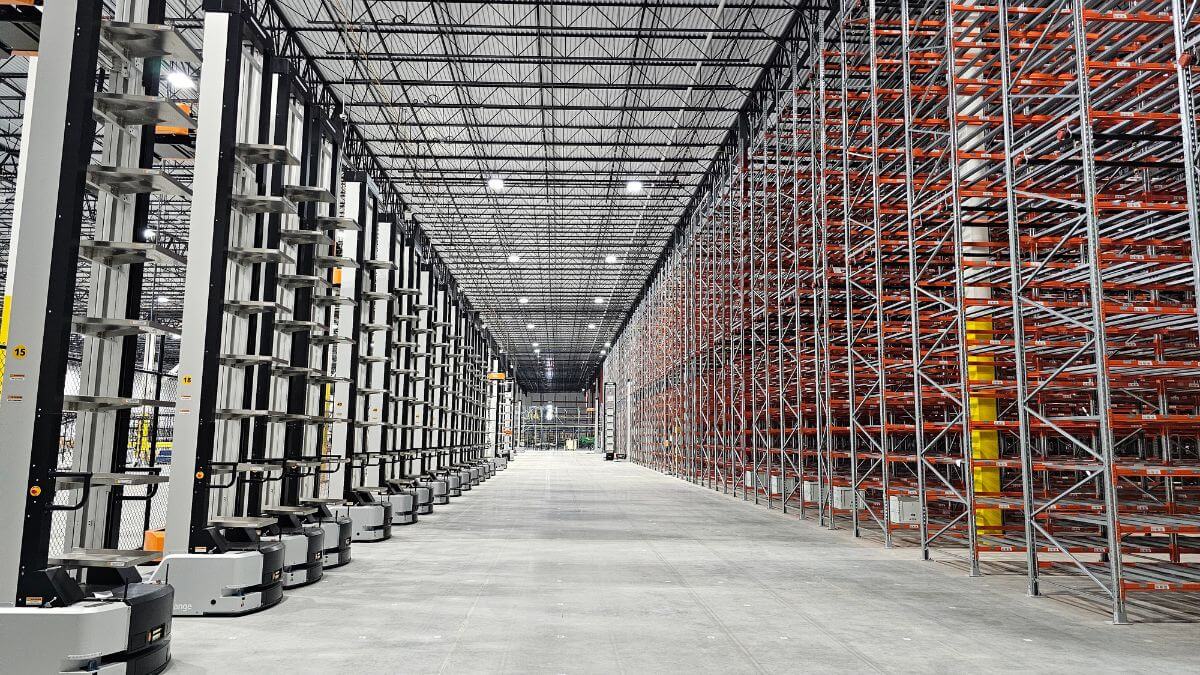

Automated warehouses are mainly classified according to the type of unit loads they handle and the automation components used. Another possible differentiation is in the racking itself: either direct access (single deep) or compact (double deep or greater depth) systems can be offered.

Automated warehouses according to type of load

Warehouses with integrated automated systems can be classified according to whether the unit loads stored are high or light in weight and volume.

- Automated storage for heavy loads or pallets.

Automated pallet storage is generally handled with stacker cranes. These devices are installed on each aisle and due to the variety of types, sizes and features available in the market, it is easy to find one suited to the specific needs of your warehouse.

- Automated storage for light loads or cartons.

For automated carton storage, the Miniload system is mainly used. It stands out for its compact and high-density design, maximising the use of space and height available in the warehouse to reduce the number of work aisles.

This characteristic is particularly useful to optimise storage in facilities with limited space.

Automated warehouses according to storage density

Depending on the number of products to be stored, the number of references and available space, two solutions can be implemented: automated warehouses with direct access or compact storage systems.

Automated warehouses with direct access racking systems are ideal for companies that manage numerous references with a low volume of pallets. The following options can be chosen in this category:

- Single deep

The stacker crane directly accesses each pallet located on the aisle where it is operating, enabling quick and efficient product handling.

- Double deep

Two pallets are placed in each location, one behind the other. To access the pallet in the second position, you will need to move the front pallet. This system offers greater storage capacity compared to single deep racking and requires fewer stacker cranes.

Automated warehouses with compact storage systems significantly increase storage capacity compared to direct access systems, as they minimise the number of aisles required. This type of solution is ideal for companies that handle a small number of references, but with a high volume of pallets for each one, being especially appropriate for mass consumption products.

Automated warehouses according to their structure and construction

Automated warehouses can be installed inside a warehouse or form part of the structure of the building.

Warehouses inside a normal warehouse are normally between 13 and 15 metres high. Whether it is a new or existing building, racking specifically designed to bear the loads and stresses generated by the stacker cranes is installed inside it. In addition, at the top of the storage aisles, additional structures are added to support the upper rail of the stacker cranes, thus ensuring their correct operation.

Clad-rack warehouses, however, are made up of racking that supports the entire structure, including the roof and side enclosures. When building these types of warehouses, it is essential to consider factors such as the weight of the goods, the loads generated by the handling equipment, wind resistance and the seismic coefficient of the area. The height of a clad-rack warehouse exceeds that of traditional warehouses and can reach over 40 metres, being limited solely by local regulations or the lifting capacities of forklifts and stacker cranes.

Automated warehouses according to the required temperature

An automated warehouse, whether for pallets or cartons, can operate at ambient temperature, in temperature-controlled conditions or in a freezing environment. In fact, automated systems are usually ideal for temperature-controlled storage for several reasons:

- It eliminates the need for people to work outdoors.

- It minimises cold loss, which results in significant energy savings.

- It optimises use of the available space.

- It facilitates constant stock control through an efficient management system.

There are 3 types of warehouses according to ambient temperature:

- Automated warehouses at ambient temperature

Automated warehouses at ambient temperature are facilities that do not require special thermal conditions for product storage.

They are mainly used for goods that are not affected by changes in ambient temperature, such as non-perishable products, consumer durable goods, industrial tools and components.

By eliminating manual intervention, precision and speed in internal logistics are improved, reducing operating costs and minimising errors.

- Refrigerated or temperature-controlled automated warehouses

Refrigerated or temperature-controlled automated warehouses are designed for products that require maintaining specific temperatures to preserve their quality and safety. They are normally used in food, pharmaceutical and chemical industries, where it is crucial to guarantee the cold chain.

Various sensors and monitoring systems ensure that the temperature is maintained within the appropriate ranges, avoiding spoilage or losses. Automation also reduces the exposure of products to external heat during their handling.

Energy efficiency is key, and the systems are optimised to reduce electricity consumption, while maintaining the ideal environmental conditions.

- Automated warehouses in a freezing environment

Automated warehouses in a freezing environment are highly specialised facilities designed for keeping products at below zero temperatures, generally between -15°C y -40°C, depending on the requirements of the stored products. They are essential in the food industry, particularly for products such as meat, fish and frozen products, as well as in some pharmaceutical and biomedical sectors.

Automation in these warehouses not only improves operational efficiency, but also protects workers from being exposed to extreme temperatures for long periods of time.

Automated warehouses according to level of automation

There are different degrees of automation, which range from manual warehouses with a minimum level of automation to those with fully automated operations.

Semi-automated warehouse

An example of this level would be a semi-automated Pallet Shuttle system. In this case, a motorised pallet shuttle autonomously moves the goods within the storage channels. However, an operator will have to place or remove the goods at each location and relocate the shuttle to different channels when necessary.

Fully automated warehouse

These facilities fully entrust the transport and storage of goods to advanced handling systems. Automation can be complete, with stacker cranes and conveyors that manage all goods movements, or mixed, where only some products are stored automatically, while others are handled manually or semi-automatically.

Advantages of the automated warehouse over the traditional warehouse

Automated storage has many advantages over traditional storage systems.

Firstly, it increases efficiency and productivity by minimising downtime, increasing the storage capacity and expediting product retrieval. By automating product handling, the risk of human error is reduced, improving accuracy and speed in the retrieval process. In addition, an automated warehouse optimises space, as the system can be adapted to demand and to changes in inventory turnover.

Finally, automated storage improves product handling safety, since the robots and storage units are designed to handle and transport products safely and undamaged.

Automated storage, the present and future of logistics

Automated storage has become a key solution in modern logistics, transforming the way in which companies manage their inventory.

This type of storage not only optimises the use of space, but also improves operational efficiency by automating tasks such as transportation, sorting and retrieval of goods. Thanks to advanced technologies, automated warehouses enable precise stock control, reduce human errors and expedite order preparation. They are also fundamental to adapt to the growing demand for fast delivery and product customisation.

As technology advances, the future of logistics will be increasingly determined by complete automation, where the processes will be faster, more precise and sustainable, meeting the demands of an ever-evolving global market.

What technologies are used in automated warehouses?

Different types of technologies are used for the automation of warehouse tasks:

- Robots: Warehouse robots are designed to move and handle goods inside the warehouse. There are several types of robots used in these environments, such as autonomous mobile robots (AMR), articulated arm robots and palletising robots, among others.

- Automated conveyors: Automated conveyors are systems that facilitate product movement inside the warehouse without requiring human intervention. They can include roller conveyors, belt conveyors, chain conveyors, among other types.

- Automated control systems: These systems are computer systems that manage and coordinate storage processes and inventory management in the warehouse. These systems allow task programming and control over the movements of robots and conveyors.

- Inventory management software: Inventory management software is used to monitor and control inventory in the warehouse ensuring that there is sufficient stock to meet demand. These types of systems are easy to integrate with other warehouse automation systems in order to optimise inventory management.

- Communication systems: Communication systems in warehouses refer to the exchange of information between warehouse management software and automation devices. These systems ensure the efficient coordination of product storage and retrieval operations.

There are different types of automated warehouses according to their construction, the type of goods stored, their compactness, their sector, etc. Whatever type of warehouse you have, at AR Racking we can help you with the automation process. Contact our team and they will advise you on the best option for your needs.