A freezing chamber is a place where goods are supplied at temperatures below 0º and where various processes can be carried out to preserve the quality of food, health products and pharmaceuticals.

Companies dedicated to the cold sector face different challenges, such as optimising storage space, correctly managing and tracking goods, and minimising energy expenditure.

Differences between a freezing chamber and a cold store

The purpose of a freezing chamber is to keep a product for a long time without risk of spoilage. By contrast, a cold store is used to keep the product at an optimal temperature for its consumption and to prevent short-term spoilage. The choice of one option or another will depend on the business needs.

Freezing chambers and cold stores must be built with sandwich panels, which act as insulating elements to stop the temperature from being transferred to the outside. The only difference lies in the floor: freezing chambers need to insulate the floor to prevent condensation, while cold stores do not require this insulation.

They are usually equipped with the same storage systems; choosing one or the other will depend on the storage capacity required and their ease of use for managing the goods.

Other types of cold storage

Along with freezing chambers and cold stores, there are other types of cold storage environments.

Temperature-controlled warehouses

Unlike refrigerated warehouses, temperature-controlled warehouses maintain a constant temperature, although not necessarily below freezing. These warehouses are ideal for fresh produce such as fruits and vegetables, which require refrigeration but not freezing. Maintaining an appropriate temperature in these warehouses helps prolong the shelf life of products and maintain their quality.

Refrigerated containers

Refrigerated containers are mobile units equipped with refrigeration and temperature control systems, used primarily for the transport of perishable products by sea, land or rail. These containers ensure that products are kept at the right temperature during transportation, preventing decomposition and preserving quality until their final destination.

Cold rooms

Cold rooms are smaller facilities than cold stores and are used for the temporary storage of products at a controlled temperature. They are common in supermarkets, restaurants and distribution centres where it is necessary to store perishable products for short periods before distribution or consumption. These rooms allow quick and efficient access to the products, maintaining their freshness.

Refrigerated vehicles

Refrigerated vehicles, such as trucks or vans, are equipped with built-in refrigeration systems to maintain the proper temperature during the transport of perishable products. These vehicles are a key part of the supply chain, ensuring that products reach their final destination in optimal conditions, without loss of quality.

Main challenges of subzero storage

The main problems or challenges to overcome when implementing industrial storage in subzero environmental conditions are the following:

Temperature maintenance

One of the main challenges of subzero storage is to maintain a constant temperature within a specific range. Small temperature variations can result in loss of quality or decomposition of the stored products. It is crucial to implement efficient temperature monitoring and control systems to avoid these variations.

Humidity control

Humidity is another critical factor in cold storage. Excessive humidity can lead to the growth of bacteria and mould in food, compromising its safety and quality. It is important to maintain an adequate humidity balance in the facility to prevent these problems.

Handling during transport

The transport of perishable products presents significant logistical challenges, especially in maintaining the proper temperature throughout the process. Products may be exposed to undesirable temperatures during loading and unloading, as well as during long journeys. Using refrigerated vehicles and proper handling procedures is essential to minimising these risks.

Inventory management

Improper inventory control can lead to food loss due to expiration or spoilage. It is essential to accurately track what is in storage, the quantity and how long each product has been stored. Effective inventory management systems help prevent waste and optimise product rotation.

Energy efficiency

Refrigeration systems are large energy consumers, which can significantly increase operating costs and environmental impact. Implementing energy-efficient technologies and practices is a constant challenge to reduce these costs and minimise the ecological footprint.

Keys to designing an industrial freezing chamber

A correct distribution of operations in a freezing chamber significantly improves logistical efficiency. When designing these facilities, it is essential to make decisions that maximise the use of available surface area and ensure smooth and efficient operations.

Inflows and outflows: for receipts and shipments, the freezing chambers usually have a refrigerated antechamber where quality controls of the products are carried out.

These chambers often have a SAS (Security Airlock System) which consists of two high-speed doors (one in the chamber and one outside) that are never open simultaneously. The function of this system is to avoid sudden changes in temperature, as well as to prevent cold loss and condensation.

Storage area: it must be equipped with racking adapted to the available space and guaranteeing greater performance. In addition, it is essential to ensure proper ventilation over the entire surface.

Order preparation: it is a complicated process which in these cases is carried out at negative temperatures, so solutions that facilitate it must be found.

Suitable storage systems for freezing chambers

For any company that handles goods that require a controlled temperature, such as the agri-food, chemical or pharmaceutical industries, it is essential to have suitable cold storage for each type of product. At AR Racking we have extensive experience in implementing controlled temperature warehouses for companies from these sectors.

Some common storage systems for the cold storage sector are:

Mobile pallet racking

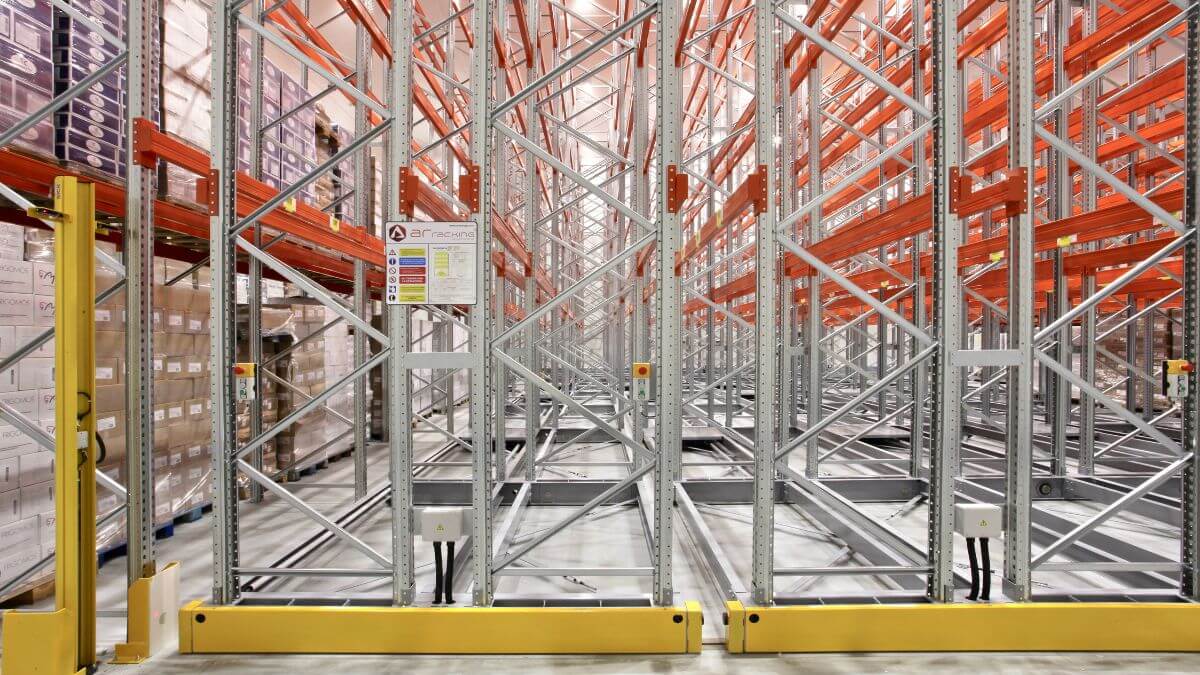

Mobile pallet racking is an exceptional solution for storage in cold stores or freezing chambers, as it is specifically designed to maximise the use of space and minimise the volume to be cooled. This system allows the racking to move laterally, eliminating the need for permanent aisles and creating a single mobile aisle where and when needed. This not only optimises the available space, but also significantly reduces the area that needs to be refrigerated, resulting in lower energy and operating costs.

A notable feature of this racking is the “night setting” mode. During periods of inactivity, the racking can be opened slightly to improve air circulation within the chamber. This feature ensures a more even temperature distribution, avoiding the formation of variable temperature zones that could affect the quality of stored products.

In short, mobile pallet racking is ideal for freezing and refrigerated environments due to its energy efficiency, space optimisation and ability to maintain consistent storage conditions.

Drive in Compact Pallet Racking Systems

Drive In compact pallet racking is particularly suitable for warehouses with cold rooms or freezing chambers due to its ability to maximise available space through a highly compact design.

This storage system allows forklifts to enter the aisles formed by the racking to deposit and remove loads, eliminating the need for additional aisles. This results in more efficient use of horizontal and vertical space, which is crucial in environments where temperature control is vital.

Compact storage not only optimises the use of space, but also contributes to a more homogeneous distribution of temperature in the chamber. By reducing the empty spaces between products, the efficiency of the refrigeration system is improved, allowing for faster and more uniform cooling of the products.

This system also helps reduce operating costs by reducing the volume of air that needs to be cooled and by improving the energy efficiency of the installation. For these reasons, Drive In compact pallet racking is a preferred option for cold and freezing storage.

Clad-rack warehouses

Clad-rack warehouses are an optimal solution for warehouses operating in extreme cold conditions or in freezing chambers, due to their robust and adaptable design. In this system, the racking is not only used to store products, but also forms an integral part of the building structure. This eliminates the need for columns and other additional supporting elements, allowing for more efficient use of the available space.

In addition, clad-rack warehouses facilitate the integration of refrigeration and temperature control systems, ensuring uniform cold distribution throughout the facility. This not only helps maintain the quality and safety of the stored products, but also optimises energy consumption, reducing operating costs and environmental impact.

For many companies in sectors such as food or pharmaceuticals, the freezing chamber is an essential work space. It must provide the greatest possible storage capacity and maximise energy use to be sufficiently effective.

At AR Racking we have a long track record in the design and equipping of cold storage facilities. Contact our team of experts to help you with your company’s needs.