Although industrial storage is generally associated with heavy loads, mostly homogeneously grouped on pallets, industrial goods can also be stored in racking systems for picking of lighter loads such as cartons and, therefore, manually handled.

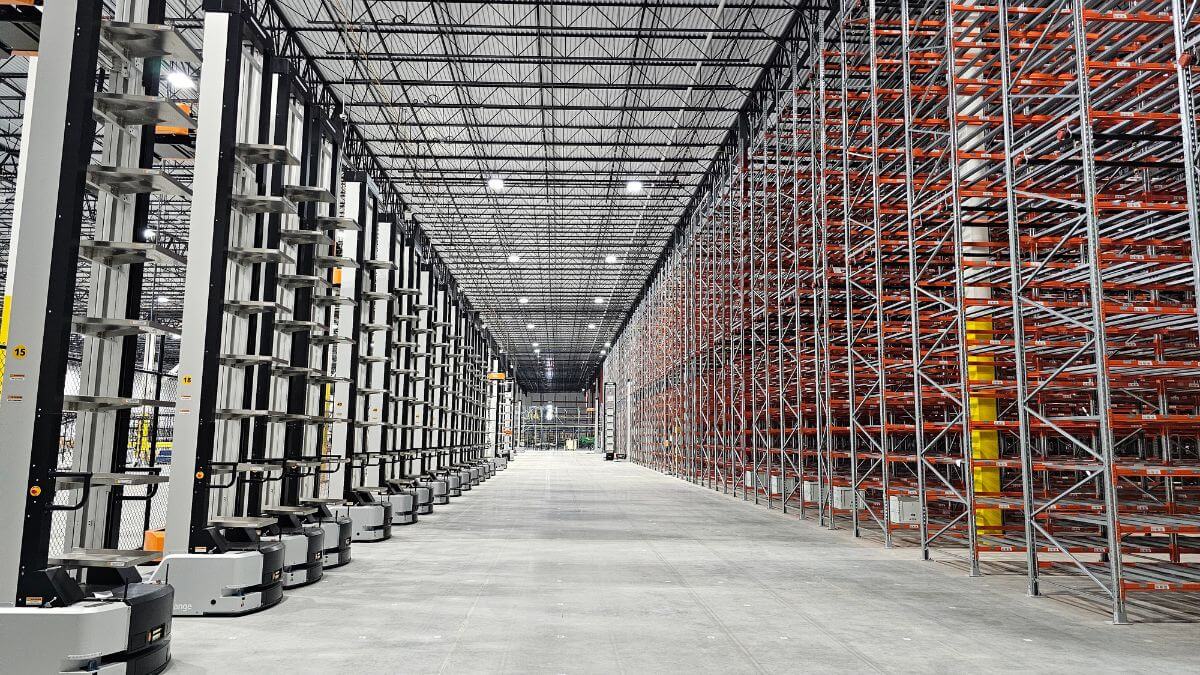

Those picking warehouses or distribution centres in which goods are stored and whose flow of movement is manual have longspan shelving or carton flow rack systems designed for manual storage and with a capacity of up to 1000 kg per rack.

In this publication we will compare the characteristics and advantages of longspan shelving and carton flow rack systems.

General characteristics of picking solutions

The main differentiating factor of picking solutions is, as mentioned, that instead of storing pallet loads their function is to store cartons or medium and light loads. But what other characteristics are typical of racking systems for medium loads?

- Their most common location in the main warehouse areas is usually the order preparation area. Picking solutions are common in spaces designed for files or areas for storing materials and packaging units that can be handled manually by operators.

- These are very versatile racking systems: they come in a wide variety of measurements and offer a wide range of components and accessories, making both adjustable and live storage picking a very scalable storage solution perfectly adapted to the specific logistics needs of companies with medium or light loads.

- Quick return on investment: the installation and maintenance of picking solutions does not entail high costs and is also a storage solution that responds immediately to logistics needs.

- Improved inventory control: longspan shelving or carton flow rack systems enable immediate visualisation of the goods, facilitating simple, fast and efficient stock management.

Although picking solutions have the above-mentioned characteristics in common, there are different types of industrial racking for picking, each one with its own specific characteristics.

The most popular solutions for the storage of cartons or medium and light loads are as follows: longspan shelving and carton flow rack systems.

Although they share some similarities, the main differences between longspan shelving and carton flow rack systems are as follows:

Longspan shelving systems:

- What: Longspan Shelving systems are an optimal solution for the storage of medium and small-size products.

- How: These types of racking systems have metal or chipboard panels on which the load to be stored is deposited.

- General uses: Longspan Shelving is a very common system in sectors such as spare parts warehouses, car parts, paints, industrial supplies and hardware stores, merchandising, pharmacy warehouses, supermarkets and cash & carry, distribution of electrical material, etc.

- Compatibility or adaptability: It is the most robust manual loading system, which does not prevent it from being a solution for easy regulation of load levels every 50 mm and with a wide variety of components and accessories (dividers, mesh racks, etc.) making it adaptable to all kinds of manual loads.

- Main advantage: Longspan Shelving systems have direct access to the units stored and a high load capacity to be a manual storage system.

Carton flow rack systems:

- What: Carton Flow Rack systems without a high-density storage system for cartons and light products.

- How: The goods slide on pulley rails with a slight incline arranged on different levels that make up the storage lanes. Carton Flow Rack systems use the FIFO system, so the first carton in is the first carton out.

- General uses: Carton Flow Rack systems can be used in many sectors, but it is common for warehouses in which this system is installed to have a high volume of rotation.

- Compatibility or adaptability: Allows the installation of pallet racking solutions at higher levels. In addition, Carton Flow Rack systems make it possible to modify the incline and the distances between pulley rails to adapt to the different sizes and shapes of cartons.

- Main advantage: High-density storage and also agile product rotation and perfect stock management.

Comparison between Longspan Shelving and Carton Flow Rack systems

| Longspan Shelving systems | Carton Flow Rack systems | |

| Load arrangement | On metal or chipboard trays | Pulley rails |

| Direct access to the goods | Yes | No |

| High-density storage | No | Yes |

| Product rotation | Medium | High |

| Differentiating factor | Robustness and load capacity | Agile order preparation |

| Influence over stock | Immediate order and control | Facilitates inventory flow |

| Enables pallet racking | No | Yes, at higher levels |

Picking solutions therefore ensure great stability and can be completed with different accessories to meet any type of storage need. However, it is important to be aware of factors such as the load access need, product rotation and space utilisation possibilities before fitting out the warehouse with one type of picking solution or another.

Full information on Longspan Shelving or Carton Flow Rack systems.